23

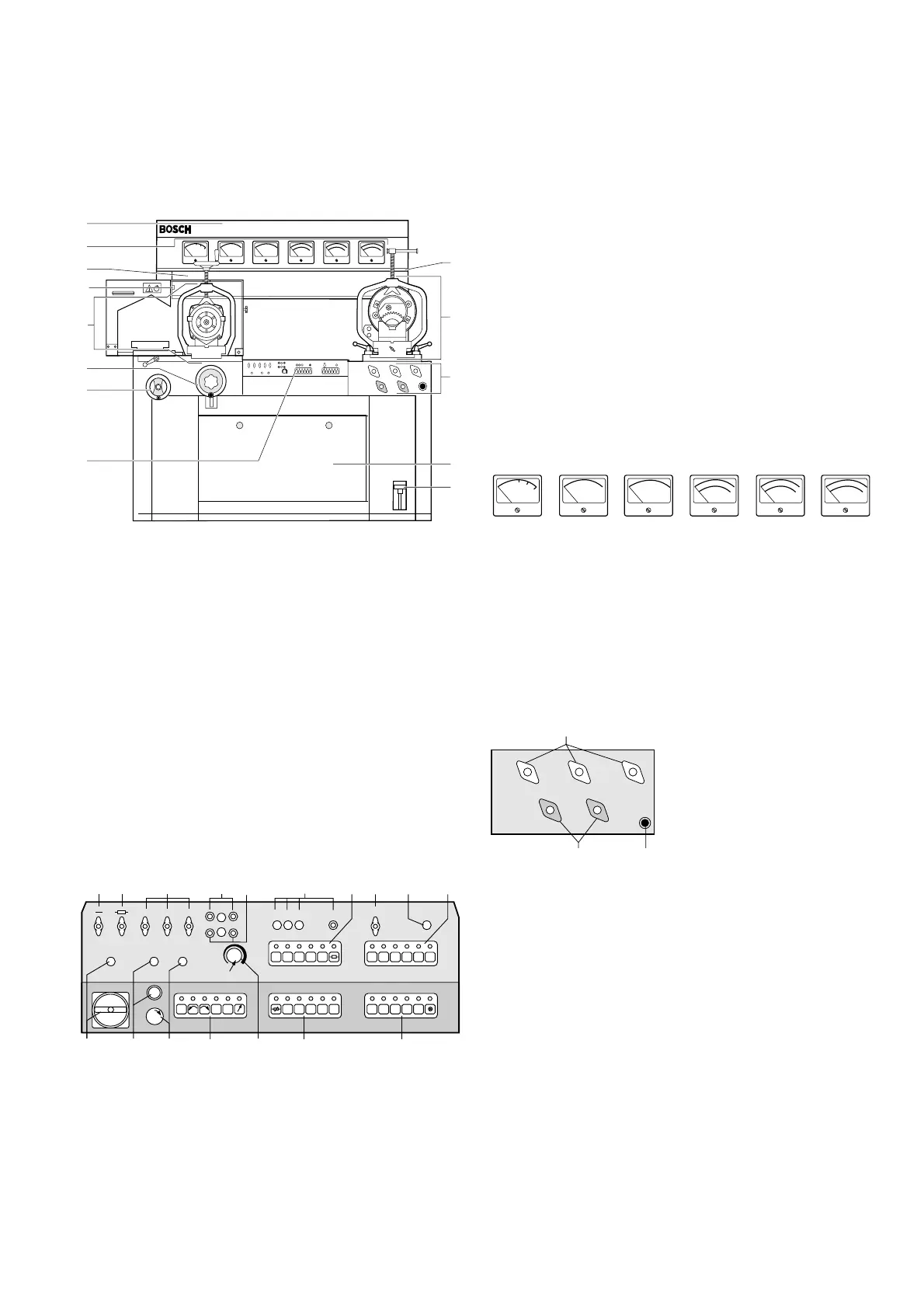

3. Description of Test Bench

The KPS 003 combination test bench consists of a generator

testing section, a starting motor testing section, indicator unit and

operating unit.

Fig. 1Fig. 1

Fig. 1Fig. 1

Fig. 1: Overall view

1 Operating panel for generator and starting-motor testing

2 Variable load resistor (generator testing)

3 Handwheel for height adjustment of clamping table, with stop (for

generators)

4 Generator test table with protective cowl

5 Socket for rotational speed sensor (generator testing)

6 Stacking plate

7 Indicators

8 Lighting console

9 Socket for rotational speed sensor (starting motor testing)

10 Starting motor test table

11 Terminals for starting motor

12 Battery compartment, lockable cover containing wiring and acces-

sories

13 Operating pedal for starting motor loading device (drum brake)

Fig. 2:Fig. 2:

Fig. 2:Fig. 2:

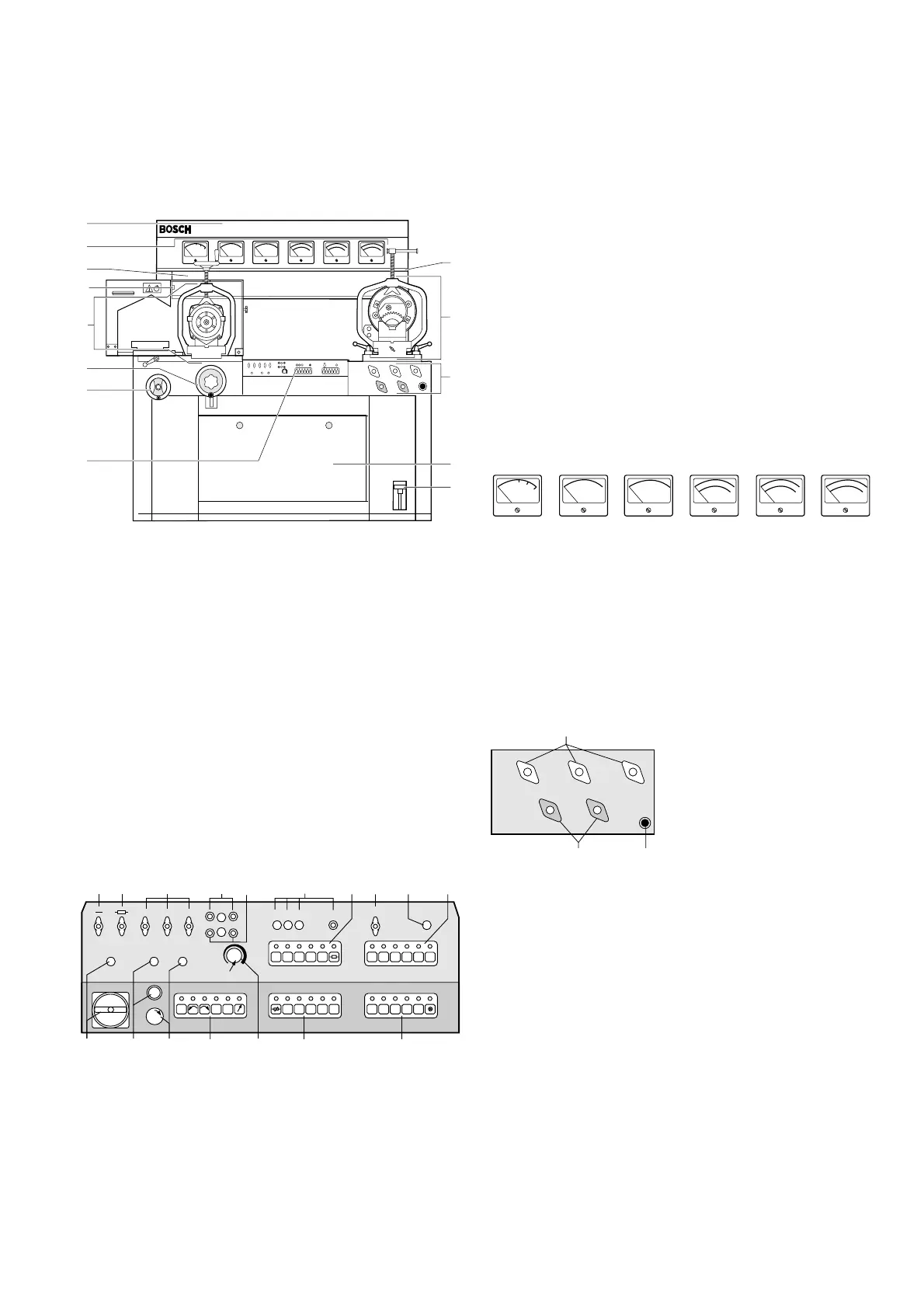

Fig. 2: Operating panel

20 Terminal to battery - (generator testing)

21 Terminal to the load resistor (generator testing)

22 Terminal to battery + (generator testing)

23 Connector bushings for ammeter 10A (generator testing)

24 Connector bushings for ammeter 10A (generator testing)

25 Charge indicator lamps with connector bushing D + / 61

(Generator testing)

26 Voltage selection key,

INT/EXTINT/EXT

INT/EXTINT/EXT

INT/EXT key, back-up resistance

(generator testing)

27 Terminal for terminal 50 for actuating the engagement switch on

starting motors (starting motor testing)

28

AKKU MINUSAKKU MINUS

AKKU MINUSAKKU MINUS

AKKU MINUS indicator lamp

29 Voltage selection key, current selection (starting motor testing)

AKKU MINUSAKKU MINUS

AKKU MINUSAKKU MINUS

AKKU MINUS key (starting motor and generator testing)

30

Key (6000/12000 rpm) for rotational speed selection (generator and

starting motor testing)

Key (60/120 A) measuring-range selection generator testing

LampLamp

LampLamp

Lamp

key for lighting

31 Key for load resistances (generator testing)

32 Drive motor rotational speed adjustment (generator testing)

33 Key for selecting direction and speed of rotation, drive motor

(generator testing)

34

EMERGENCYEMERGENCY

EMERGENCYEMERGENCY

EMERGENCY push-button = drive

OffOff

OffOff

Off and indicator lamp

OnOn

OnOn

On

(generator testing)

35

MOTORMOTOR

MOTORMOTOR

MOTOR push-button and indicator lamp (generator testing)

36 Main switch =

EMERGENCY-OFFEMERGENCY-OFF

EMERGENCY-OFFEMERGENCY-OFF

EMERGENCY-OFF function and indicator lamp

Fig. 3Fig. 3

Fig. 3Fig. 3

Fig. 3: Display instrument unit

40 Rotational speed 6000 rpm

41 Ammeter 60/120 A

42 Ammeter 10 A

43 Voltmeter 0-10/20/40 V

44 Rotational speed 6000/12000 rpm

45 Ammeter 300/1800 A

Fig. 4Fig. 4

Fig. 4Fig. 4

Fig. 4: Starting motor terminals

50 Terminals for starting motor plus wire 6/12/24 V

51 Starting-motor push-button

52 Terminals for starting motor minus wire

- connect small starting motor to -300 A terminal

- connect large starting motor to -1800 A terminal

458712P

120

60

A

41

V

43

min

x100

44

10

A

42

1800

300

A

45

-1

40

min

x100

-1

458468P

50

52

+6V

+12V

+24V

-300A

-1800A

51

9

11

13

8

7

6

5

4

3

2

1

12

458470P

10

120

60

A

41

V

43

min

x100

44

10

A

42

1800

300

A

45

-1

40

min

x100

-1

7 14 28 INT. EXT.

458473P

START

6V 12V 24V

300

AKKU

MINUS

123 5

RUN 1500 3000

4

RPM.

30

27

25

23

2221

20

24

RPM.

35 34

32

+6V +12V +24V

10A

A

V

+

_

6V 12V 24V D+/61

AKKU

MINUS

50

WARNING

ON/OFF

MOTOR

EMERGENCY

2826

29

31

36

33

1800

60

120

6000

12000

Loading...

Loading...