Installation 31/72

RE 92050-01-X-B1/2019.08.23, Axial piston variable pump A4VSO, BoschRexrothAG

7.2 Installation conditions

The installation position and location oftheaxial piston unit essentially determine

how itisinstalled and commissioned (such aswhen filling and air bleeding theaxial

piston unit).

▶ Fasten theaxial piston unit sothat theexpected forces and torque can

betransferred without any danger. The machine/system manufacturer

isresponsible for sizing thefasteners.

▶ Observe the permissible radial forces as indicated on page 7 of the

datasheet(Part II) on the drive shaft when transferring output drive with radial

loading. Donot use belt drives; see chapter 7.4.3 "General instructions" on

page38.

▶ Make sure theaxial piston unit isalways filled with hydraulic fluid during

commissioning and operation. Also do this also after relatively long standstill

periods, since theaxial piston unit may drain out through thehydraulic lines.

▶ Install carefully and in accordance with ATEX guidelines to prevent damage to the

bearings, housing, clamp collar and drive shaft.

▶ The case drain fluid in the case interior must be directed to the reservoir via the

highest case drain port. Use aline size that matches theport.

▶ A check valve in the drain line is only permissible on a case-by-case basis upon

request. Please consult your proper contact person atBoschRexroth.

▶ To keep noise values low, use elastic elements toisolate all connecting lines from

all vibration-capable components (e.g. reservoir).

▶ Make sure that the suction, reservoir and return lines lead into the reservoir

below the minimum fluid level in all operating conditions. This will prevent air

from being drawn inand foam from forming.

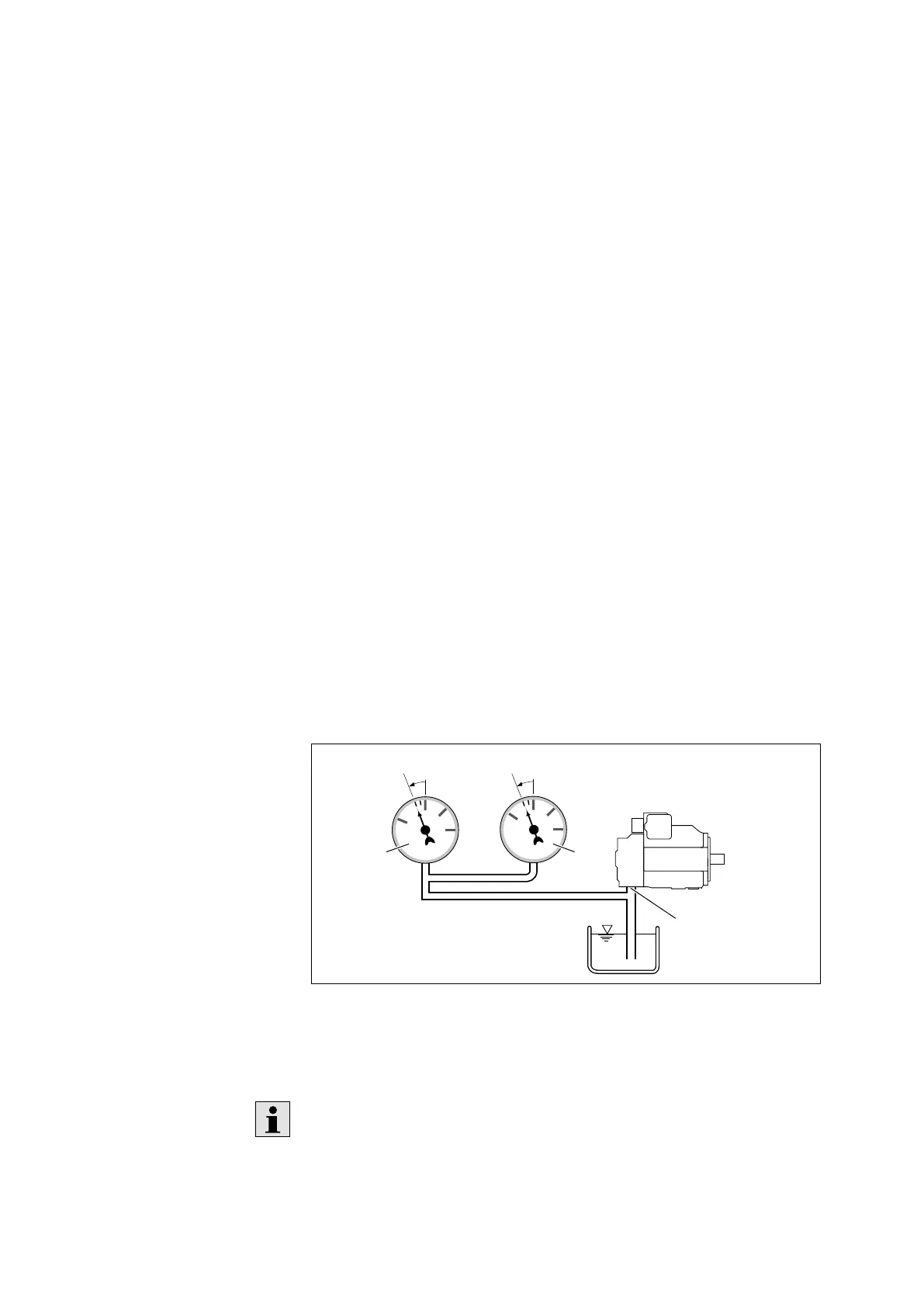

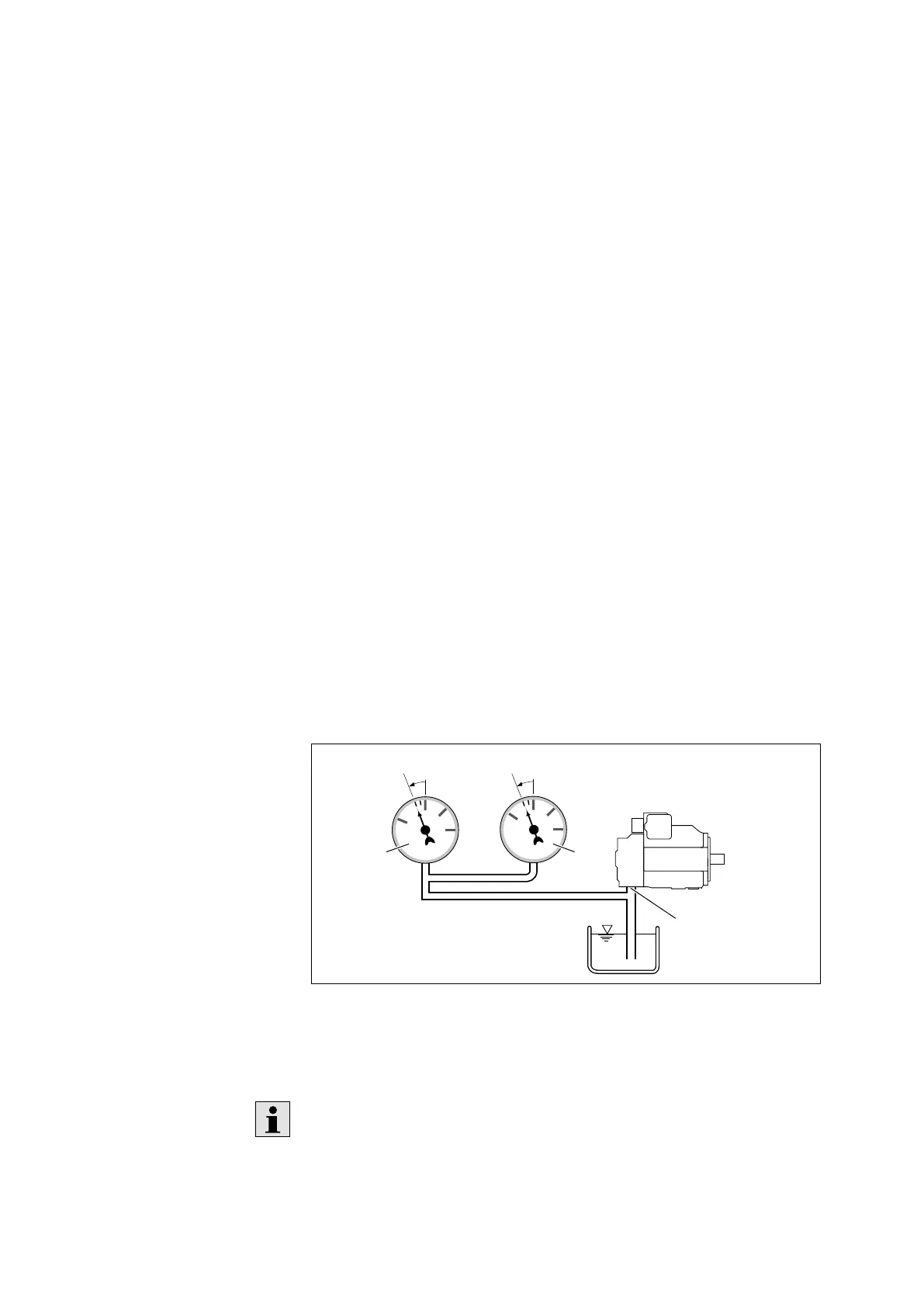

▶ Make sure that a minimum suction pressure of 0.8bar absolute is present at

portS during operation for all installation positions and installation locations

of the axial piston unit; see Fig. 5. See the data sheet (Part II) for additional

pressure levels.

1

2

3

0

0

1

2

-1

-0.2

0.8 abs.

21

S

Fig. 5: Suction pressure

1 Absolute pressure gauge

2 Standard pressure gauge (relative)

The suction conditions improve with below-reservoir installation

Loading...

Loading...