Installation 35/72

RE 92050-01-X-B1/2019.08.23, Axial piston variable pump A4VSO, BoschRexrothAG

To guarantee lubrication of the front bearing and of the shaft seal with

above-reservoir installation, Rexroth specifies a working bearing flushing at "U".

CAUTION

Risk of damage due to inadequate lubrication!

Ensure adequate lubrication

to avoid damage to the axial piston unit.

▶ Make sure the case is completely filled with hydraulic fluid during

commissioning and operation when installed with the drive shaft up

(e.g.,noairinclusions).

▶ Check the hydraulic fluid level in the housing regularly and recommission, if

necessary. With above-reservoir installation, the housing area may drain via the

drain line after longer standstill periods (air enters via the shaft seal ring) or via

the working line (gap leakage). The bearings are thus insufficiently lubricated

when recommissioning.

▶ Make sure that the suction line is always filled with hydraulic fluid during

commissioning and operation.

▶ Make sure that the bearing flushing is working properly for above-reservoir

installation and in all installation positions with the drive shaft up. To do

this, check, for example, the flushing pressure or the minimum flushing flow,

seedatasheet (Part II).

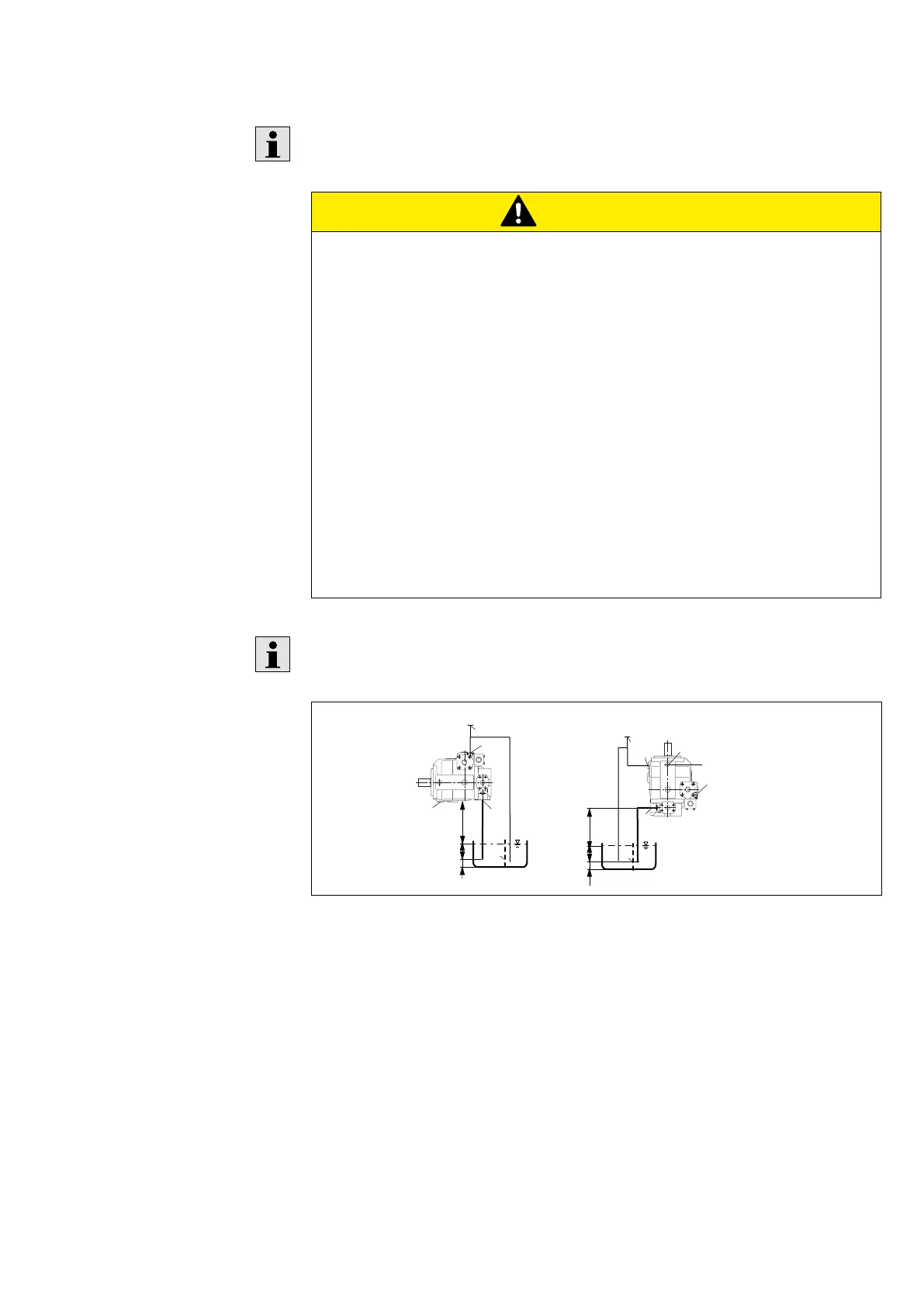

Observe themaximum permissible suction heighth

Smax

= 800mm.

Thepermissible suction heighth

S

isderived from thetotal pressure loss.

1)

5

6

SB

F

h

t min

h

min

R(L)

T

S

h

s max

F

h

t min

h

min

R(L)

T

S

h

s max

U

Fig. 8: Above-reservoir installation with horizontal installation position5 and vertical installation

position 6

1)

Install bearing flushing, please refer to data sheet (Part II) for minimum flushing flow

R(L) Fluid filling and air bleeding

(drainport)

h

min

Minimum required distance

toreservoir bottom (100mm)

T Fluid drain h

t min

Minimum required immersion depth

(200mm)

S Suction port SB Baffle (baffle plate)

U Flushing port

Loading...

Loading...