44/72 Installation

BoschRexrothAG, axial piston variable pump A4VSO, RE 92050-01-X-B1/2019.08.23

The following tightening torques apply:

• Fittings:

Observe themanufacturer's specifications regarding thetightening torques

ofthefittings used.

• Female threads inthe axial piston unit:

The maximum permissible tightening torques M

Gmax

are the maximum values for the

female threads and should not be exceeded. For values, see Table 16.

• Threaded plugs:

For the metal threaded plugs that come with the axial piston unit, the required

tightening torques for the threaded plugs M

V

apply. For values, see Table 16.

• Mounting bolts:

For mounting bolts with metric ISO threads according to DIN13 and/orASME

B1.1 threads, we recommend checking thetightening torque inindividual cases

inaccordance with VDI2230.

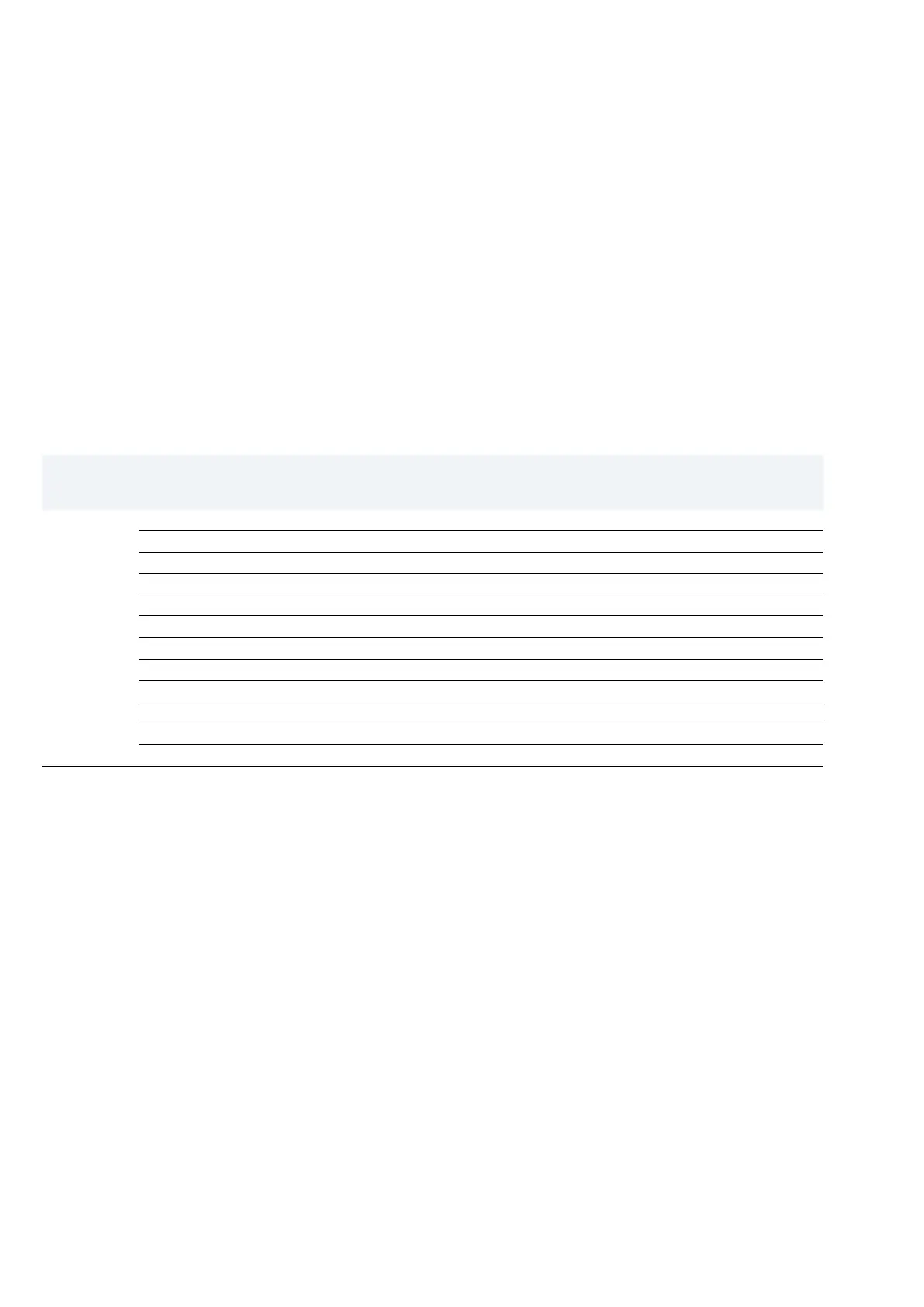

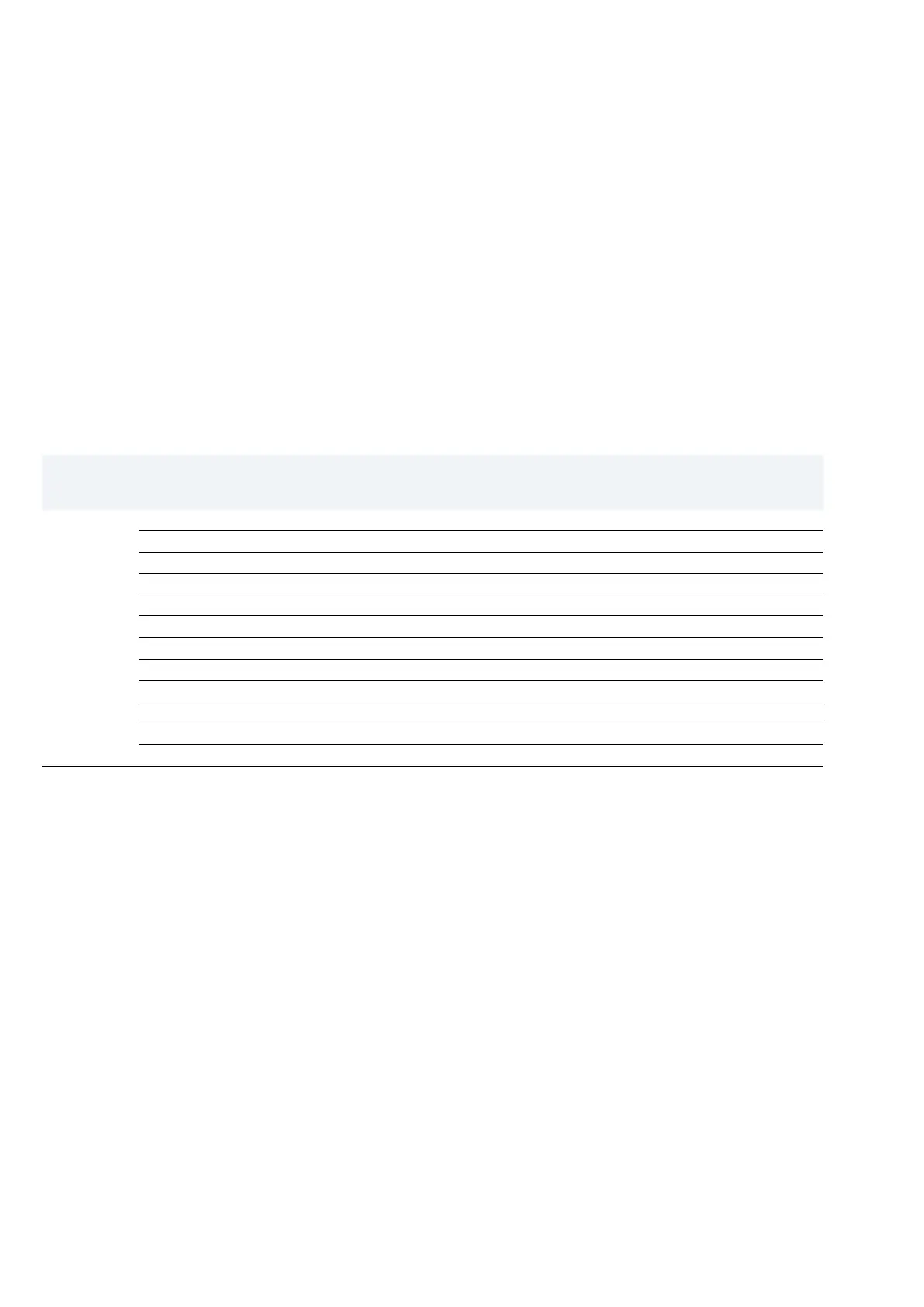

Table 16: Tightening torques for female threads and threaded plugs

Ports

Maximum permissible

tightening torque offemale

threads M

Gmax

Required tightening torque

ofthreaded plugs M

V

WAF hexagon socket

ofthethreaded plug

Standard Thread size

DIN 3852

1)

M8 x 1 10Nm 7Nm 3mm

M10 x 1 30Nm 15Nm

2)

5mm

M12 x 1.5 50Nm 25Nm

2)

6mm

M14 x 1.5 80Nm 35Nm 6mm

M16 x 1.5 100Nm 50Nm 8mm

M18 x 1.5 140Nm 60Nm 8mm

M22 x 1.5 210Nm 80Nm 10mm

M26 x 1.5 230Nm 120Nm 12mm

M27 x 2 330Nm 135Nm 12mm

M33 x 2 540Nm 225Nm 17mm

M42 x 2 720Nm 360Nm 22mm

M48 x 2 900Nm 400Nm 24mm

1)

The tightening torques of the threaded plugs M

V

apply to the unit when "dry" and to the plugs when "lightly oiled" for installation.

2)

When "lightly oiled", M

V

is reduced to 10Nm for M10 x 1 and 17Nm for M12 x 1.5. When the unit is "dry" and M

V

reduced, 10Nm for

M10x1 and 17Nm for M12x1.5, the maximum permissible pressure is 420bar.

To connect theaxial piston unit tothe hydraulic system:

1. Remove theprotective plugs and/or threaded plugs from theports where

theconnections should bemade according tothe hydraulic circuit diagram.

2. Make sure thesealing surfaces ofthehydraulic ports and functional surfaces are

not damaged.

3. Use only clean hydraulic lines orflush them before installation.

(Observechapter8.1.6 "Performing flushing cycle" onpage51 when you flush

out theentire system.)

4. If using an external bearing flushing, screw the throttle screw in port"U" in to

thestop.

5. Connect thelines inaccordance with theinstallation drawing and themachine

orsystem circuit diagram. Check that all ports are connected orplugged with

threaded plugs.

Tightening torques

Procedure

Loading...

Loading...