Electrical | 9WW & WT Models

8733943362 (2016/08)Revised 08-16

Safety controls include the following:

• High pressure switch located in the refrigerant

discharge line and wired across the HPC terminals

on the UPM.

• Low pressure switch located in the unit refrigerant

suction line and wired across terminals LPC1 and

LPC2 on the UPM.

• Water side freeze protection sensor, mounted close

to condensing water coil, monitors refrigerant

temperature between condensing water coil and

thermal expansion valve. If temperature drops

below or remains at freeze limit trip for 30 seconds,

the controller will shut down the compressor and

enter into a soft lockout condition. The default

freeze limit trip is 26°F, however this can be

changed to 15°F by cutting the R30 or Freeze1

resistor located on top of DIP switch SW1 (Refer to

Figure #3, item [3] for resistor location), Refer to

Figure #5 for sensor location

.

Figure # 5

The UPM Board includes the following features:

• ANTI-SHORT CYCLE TIMER: 5 minute delay on

break timer to prevent compressor short cycling.

• RANDOM START: Each controller has an unique

random start delay ranging from 270 to 300 seconds

on initial power up to reduce the chance of multiple

unit simultaneously starting at the same time after

power up or after a power interruption, thus

avoiding creating large electrical spike.

• LOW PRESSURE BYPASS TIMER: If the compressor

is running and the low pressure switch opens, the

controller will keep the compressor on for 120

seconds. After 2 minutes if the low pressure switch

remains open, the controllers will shut down the

compressor and enter a soft lockout. The

compressor will not be energized until the low

pressure switch closes and the anti-short cycle time

delay expires. If the low pressure switch opens 2-4

times in 1 hour, the unit will enter a hard lockout. In

order to exit hard lockout power to the unit would

need to be reset.

• BROWNOUT/SURGE/POWER INTERRUPTION

PROTECTION: The brownout protection in the UPM

board will shut does the compressor if the incoming

power falls below 18 VAC. The compressor will

remain OFF until the voltage is above 18 VAC and

ANTI-SHORT CYCLE TIMER (300 seconds) times out.

The unit will not go into a hard lockout.

• MALFUNCTION OUTPUT: Alarm output is Normally

Open (NO) dry contact. If pulse is selected the alarm

output will be pulsed. The fault output will depend

on the dip switch setting for "ALARM". If it is set to

"CONST", a constant signal will be produced to

indicate a fault has occurred and the unit requires

inspection to determine the type of fault. If it is set

to "PULSE", a pulse signal is produced and a fault

code is detected by a remote device indicating the

fault. See L.E.D Fault Indication below for blink code

explanation. The remote device must have a

malfunction detection capability when the UPM

board is set to "PULSE".

UPM Board Dry Contacts are Normally Open (NO)

NOTICE: If unit is employing a fresh water

system (no anti-freeze protection), it is

extremely important to have the Freeze1

R30 resistor set to 26°F in order to shut

down the unit at the appropriate leaving

water temperature and protect your heat

pump from freezing if a freeze sensor is

included.

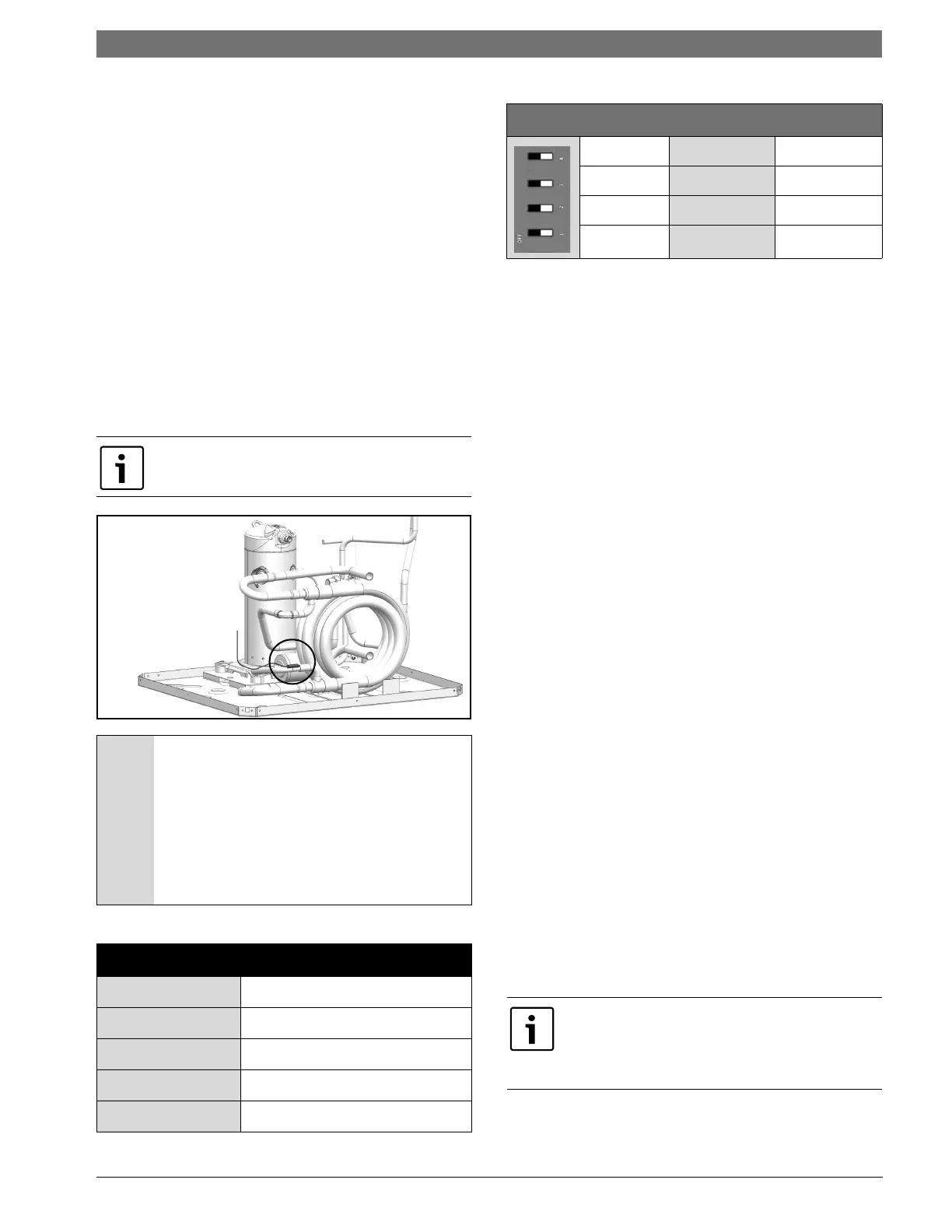

UPM Board Factory Default Settings

TEMP

26°F

LOCKOUT

2

RESET

Y

ALARM

PULSE

TEST

NO

UPM DIP SWITCH DEFAULT POSITION

lockout 42

reset

RY

alarm

Cont pulse

test

yes no

If 24 VAC output is needed, R must be wired to

ALR-COM terminal; 24 VAC will be available on

the ALR-OUT terminal when the unit is in the alarm

condition.

Loading...

Loading...