Multi-DM™ User Manual Section 4 - Introduction

BMC Document Number: DOC-0009 Rev. 5.2 Page 5

4. Introduction

4.1 About Boston Micromachines Deformable Mirrors

Boston Micromachines (BMC) Deformable Mirrors (DMs) are advanced wavefront control

devices that consist of a mirror membrane supported by an underlying actuator array.

• Each actuator can be individually deflected by electrostatic actuation,

thus changing the shape of the mirror, to achieve the desired pattern of deformation.

• BMC DMs are capable of achieving high spatial resolution shapes

due to high actuator count and low to no inter-actuator coupling.

• BMC DMs are available with continuous or segmented mirror surfaces.

• BMC DMs exhibit highly stable operation with no hysteresis.

• BMC provides compact, high resolution DM drive electronics

that are suitable for bench-top or OEM integration.

• BMC's DM Software Development Kit (SDK), including Windows and Linux hardware

drivers, software drivers for C/C++, Python, MathWorks MATLAB and National

Instruments LabVIEW software, and command line and GUI based DM control

applications.

• BMC's DM software is capable of operating multiple DM systems simultaneously.

4.2 Included Components

All Multi- series DMs are supplied with the following items:

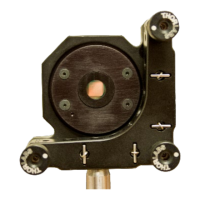

• The Multi-DM Deformable Mirror.

For detailed specifications see Section 4.3.1, Multi Deformable Mirrors.

For detailed description see Section 5.1, System Diagram.

• The Multi Driver Control Electronics.

For detailed specifications see Section 4.3.2, Multi Driver.

For detailed description see Section 5.3, Multi Driver Electronics.

• The BMC Deformable Mirror Software Development Kit (SDK).

For detailed information see Section 5.4, SDK and Demonstration Software.

• A DM- and Driver-specific configuration file.

• A DM-specific half bias flat shape data file.

• A DM- and Driver-specific System Data Sheet file.

• A USB Male A to Male Mini-B cable for connecting the Multi Driver to a PC.

• An ESD wrist strap.

• A complete set of hardware and software documentation.

Loading...

Loading...