2. Setting up GT-3 Series

2-6-2. Installing Ink

The following procedures are the steps of installing the Ink. Mount the Print Heads first by “2-4-1. Installing the

Print Heads” first.

Install the Color Ink on GT-341; both Color and White on GT-381 and GT-361.The process is not identical

between the Color and White. Confirm the process beforehand.

The Maintenance Solution should be installed before the White Ink. If the inside of the Tubes are dry, then the

White Ink will not run smoothly in the Tubes and very small bubbles will surely be produced, which may cause

serious missing nozzles in the test print.

Follow the procedures below for smooth and stable print quality.

Installing the White Ink (for GT-381 and GT-361)

When carrying out white tube cleaning, use a clean Bottle and fresh Maintenance Solution to avoid the risk of

blockages occurring inside the Print Head. When filling the bottle with the Maintenance Solution, be sure to

follow the instructions given below. Go to the procedure to installing the White Ink after you clean the Bottle.

1. Throw away the old maintenance solution first if there is some maintenance solution remaining inside the

Bottle, first discard the old maintenance solution.

2.

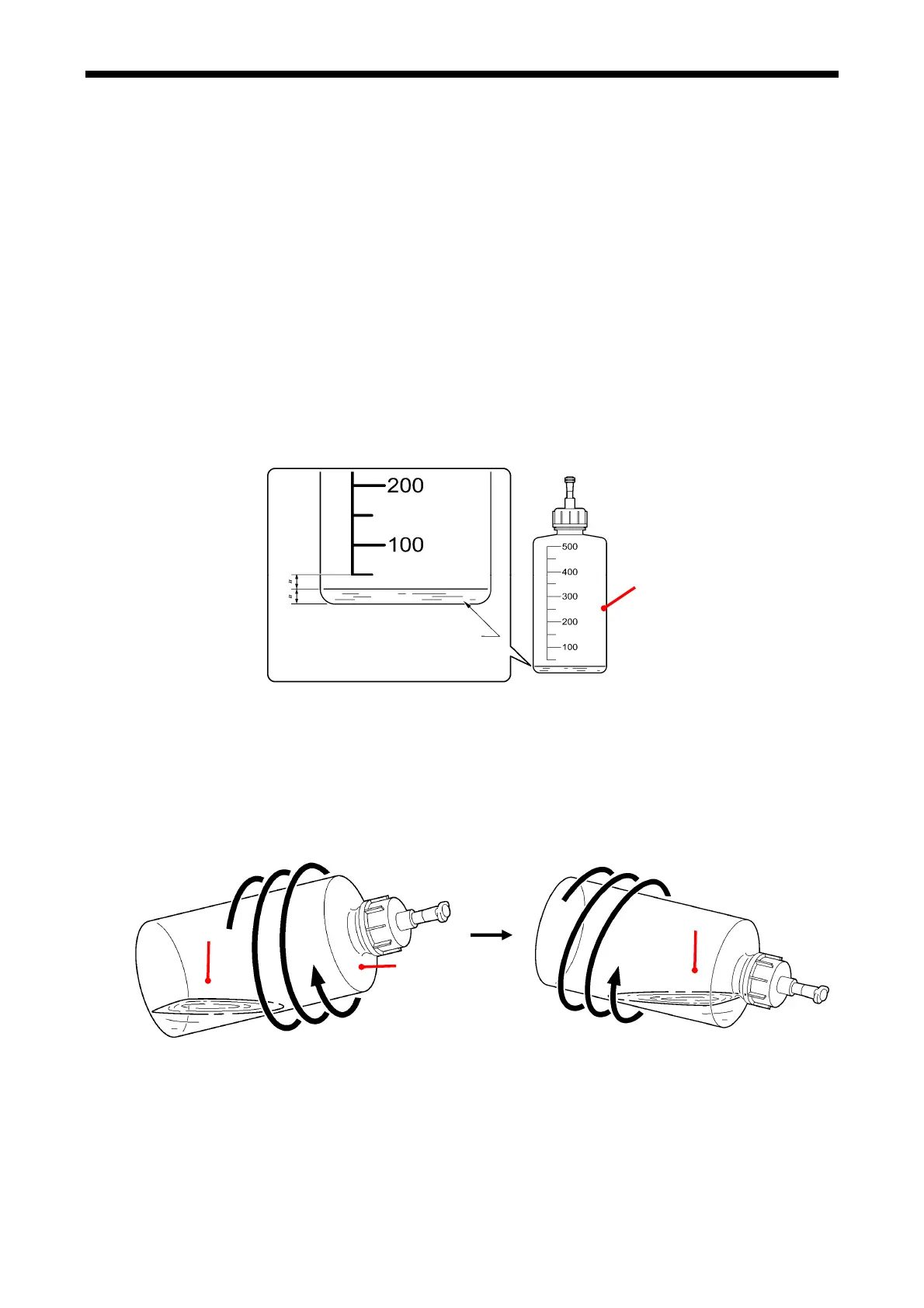

Pour about 25 ml of fresh Maintenance Solution (2) into the Bottle (1), about half-way between the

bottom and the first line on the scale.

(1)

(2)

4725M

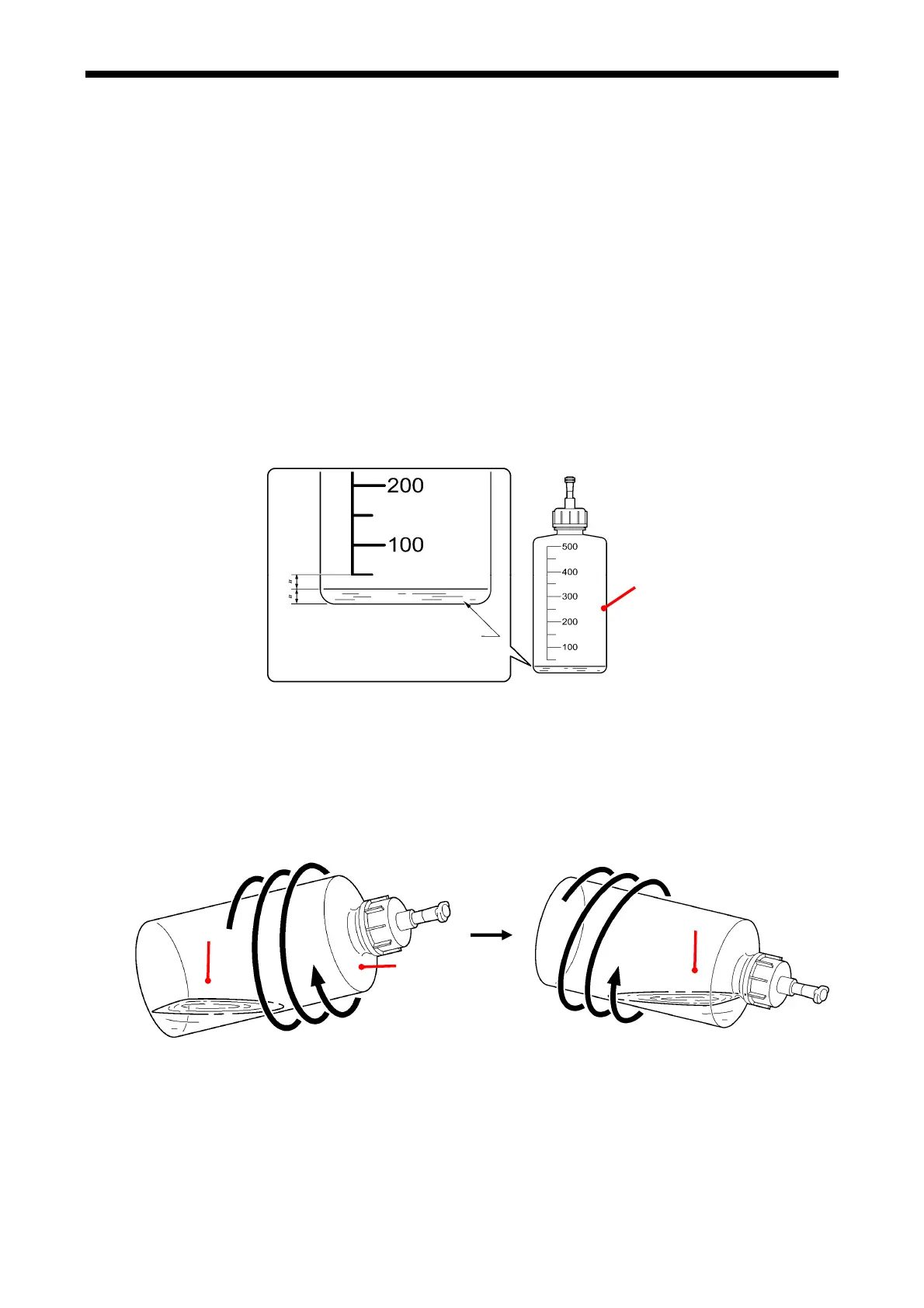

3. Tilt the Bottle (1) and rotate it about three times as shown in the illustration so that the Maintenance

Solution (2) flows around the base and sides inside the bottle to clean them.

<Note>

If you shake the Bottle with Maintenance Solution, bubbles will form and will not allow flowing around so

easily inside the bottle. Carry out the rinsing action gently so that the maintenance solution washes the

insides walls of the bottle.

62

GT-3 Series

4726M. 4727M

4. Tilt the top of the Bottle also as shown in the right figure and then rotate it three times in the same way as

described in step 3 above to clean the top and sides inside the Bottle.

5. Throw away the Maintenance Solution (2) which is inside the bottle.

6. Pour some maintenance solution into the bottle to use for carrying out tube cleaning. Carry out this step

quickly to avoid letting any dirt or other foreign particles get in at this time.

7. Fill the bottle with approx. 500cc Maintenance Solution. The printer cannot detect the volume of the

Maintenance Solution inside the Bottle. If the air goes into the Tubes and Print Heads with less

Maintenance Solution left in the Bottle, poor print quality will cause; missing nozzles will not be solved

easily in the test print.

(2)

(2)

(1)

Loading...

Loading...