291

GEARCASE

GEARCASE REMOVAL AND INSTALLATION

13

IMPORTANT: New gearcase screws are treated

with a thread-locking material. Apply Triple-Guard

grease to thre ads t o ensure th at the correct

clamping force is ach ieved when tig htening—If a

previously inst alled screw is re-used, use a wire

brush to remove any old thread-locking material or

corrosion and lu bricate threads with Triple-Guard

grease.

Install screws and washers and tighten to a torque

of:

• 3/8 in. screws – 26 to 28 ft. lbs. (35 to 38 N·m)

• 7/16 in. screw – 45 to 50 ft. lbs. (61 to 68 N·m)

Apply Triple-Guard gre ase to threads o f the trim

tab screw . Install gasket on “M”-type gearcase s.

Install an d align the trim t ab (cover on “L”-type)

with the inde x ma rks noted prior to disassemb ly.

Tighten the trim tab screw to a torque of 35 to 40

ft. lbs. (47 to 54 N· m). For adjustme nt, refer to

Trim Tab Adjustment on p. 30.

Standard rotation and counter rota-

tion trim t abs must not be inte rchanged. This

would result in inad equate cooling water sup-

ply to the propeller hub.

Place the shift rod in the shift rod lever. Install the

retaining pin and washer. Tighten pin to a torque

of 60 to 84 in. lbs. (7 to 9.5 N·m).

IMPORTANT: During break-in pe riod of a reas-

sembled gearcase, change the gearcase lubricant

between 10 to 20 hours of operation.

1. Alignment bolt

2. 3/8-16 x 1.75 in. screw

005403

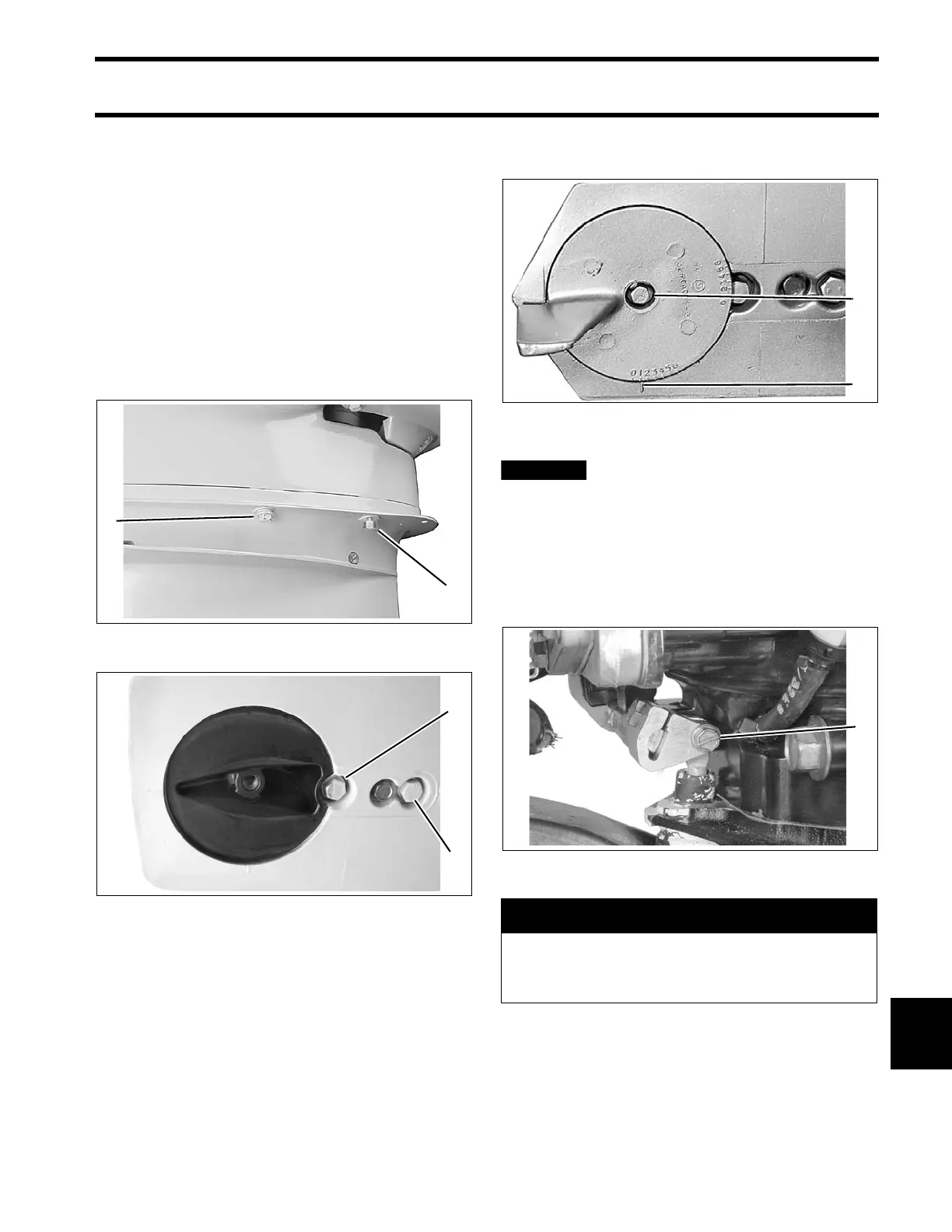

1. 3/8-16 x 3.5 in. screw

2. 7/16-14 x 3.5 in. screw

006869

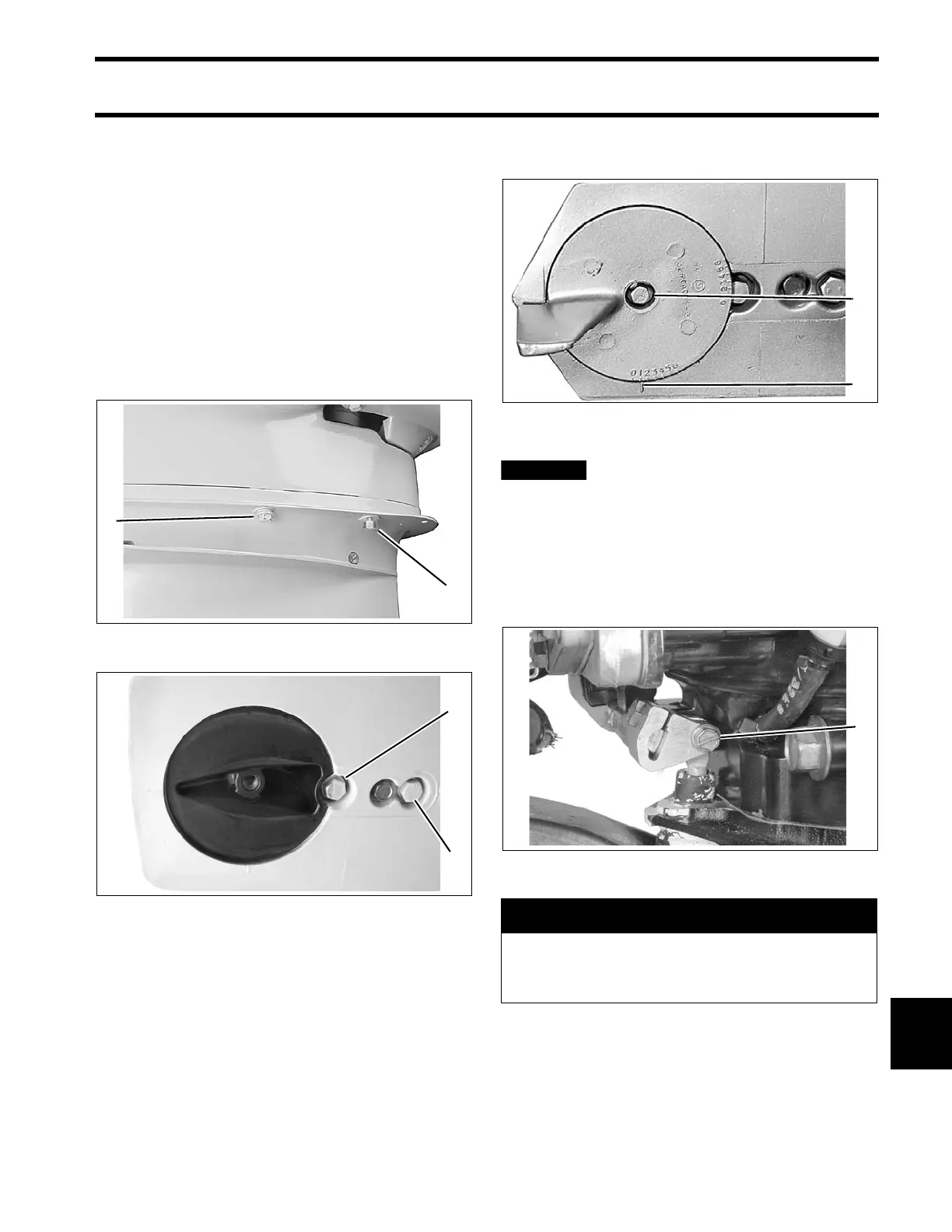

1. Trim tab screw

2. Index mark

COA3663

1. Shift rod screw 004241

A WARNING

To prevent loss of operator control, check

for proper shifting operation and adjust, if

necessary.

Loading...

Loading...