43

.ROUTINE SERVICE

ANTI-CORROSION PROTECTION

2

ANTI-CORROSION

PROTECTION

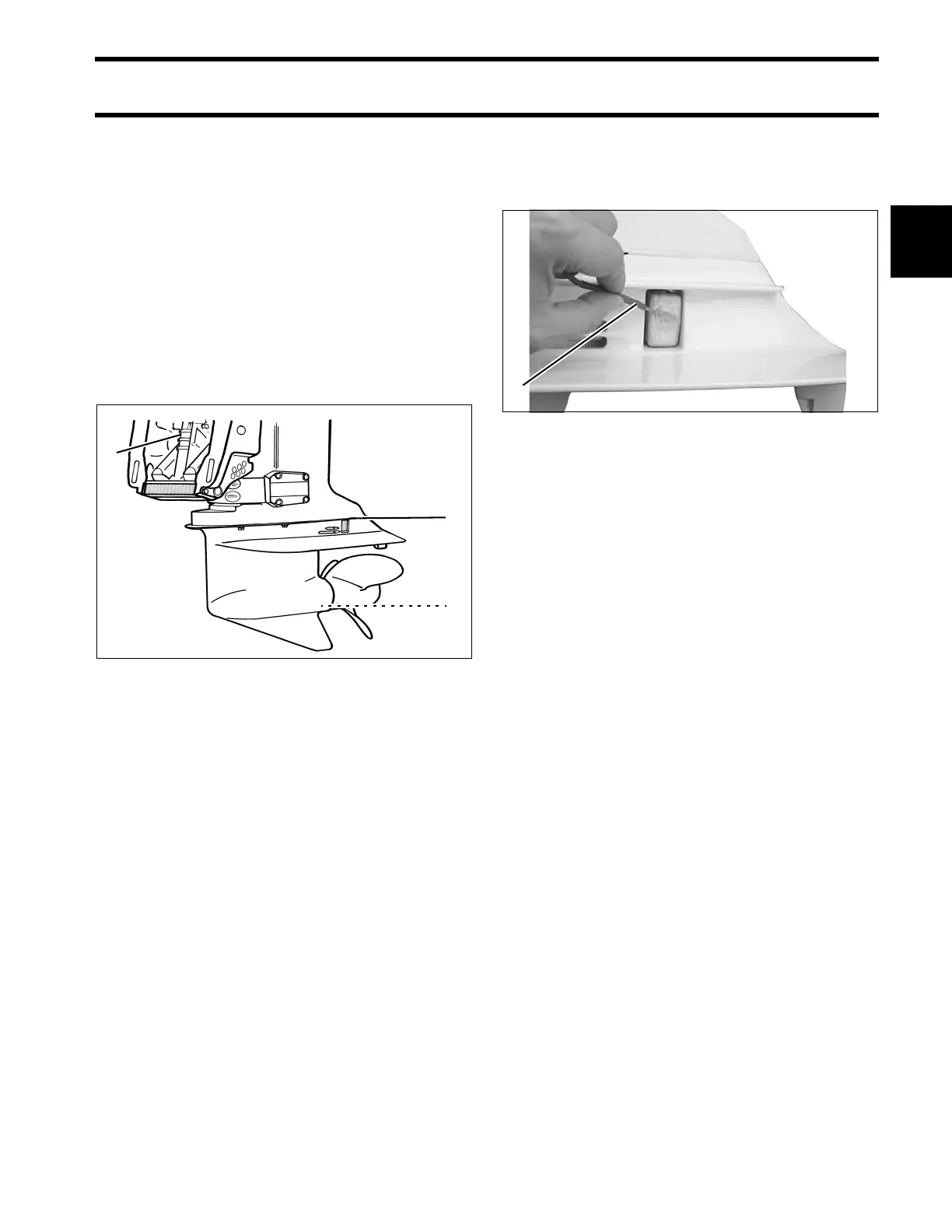

Sacrificial Anodes

Galvanic corrosion occurs in fre sh or salt wa ter.

Salt, brackish, and polluted water can accelerate

corrosion. “Sacrificial” anodes are intended to pro-

tect the underwater metal components of the out-

board from galvanic corrosion.

Outboards are equ ipped with three sacrificial

anodes.

Visually inspect ano des and metal co mponents

below water level. Erosion of anode s is normal

and indicates the anodes are functioning properly.

IMPORTANT: Anodes that are no t eroding ma y

not be properly grounded. Anodes and the mount-

ing screws must be clean an d tig ht for effective

corrosion protection.

For best anode performance:

• Replace all anodes that have eroded or disinte-

grated to two-thirds of their original size

• Do not p aint or app ly pro tective co atings to

anodes or anode fasteners

• Avoid using metal-based antifouling paint on the

boat or outboard.

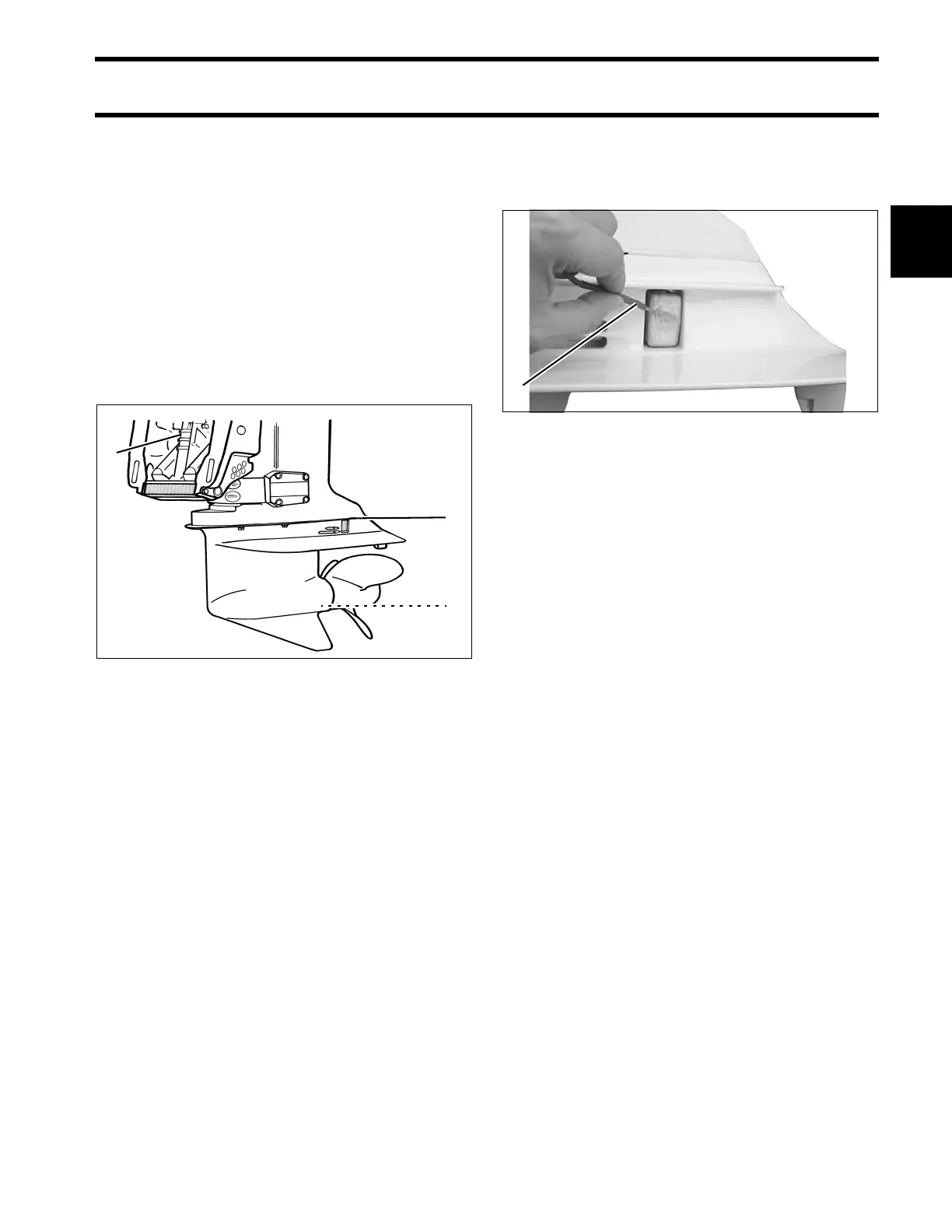

Testing Procedure – Continuity

Connect ohmmeter leads between engine ground

and anode surface.

The mete r sho uld show little or no re sistance. If

resistance is high, check the following:

• Remove the an ode and clean the area where

the anode is installed

• Clean the mounting screws

• Install the anode and test again.

Metallic Component Protection

Protect metal components on outboards from cor-

rosion. Use the following product s to minimize

corrosion:

• Anti-Corrosion Spray provides a heavy , waxy

coating to protect components

• “6 in 1” Multi-Purpose Lubricant provides a thin

film of anti-corrosion protection.

Exterior Finishes

Maintain the outboard’s ext erior finish to preve nt

corrosion and reduce oxidation:

• Use a utomotive wa x to prot ect the outboa rd’s

exterior finish from oxidation

• Clean regularly using clean wa ter and mild

detergent soap

• Touch-up damage to painted surfaces promptly.

• Protect moving compo nents with app ropriate

lubricants.

1. Stern bracket anode

2. Propeller shaft bearing housing anode

(inside of gearcase housing)

3. Gearcase housing anode

DR5082

1. Meter lead to anode 000677

Loading...

Loading...