341

TRIM AND TILT

TROUBLESHOOTING

14

If the outboa rd does not tilt as hig h as it should,

and the tilt mot or TURNS OF F at maximum tilt

(does not sound like it is st alled at the maximum

tilt position), adjust the tilt limit switch higher a nd

retest. Refer to Tilt Limit Switch Adju stment on

p. 28.

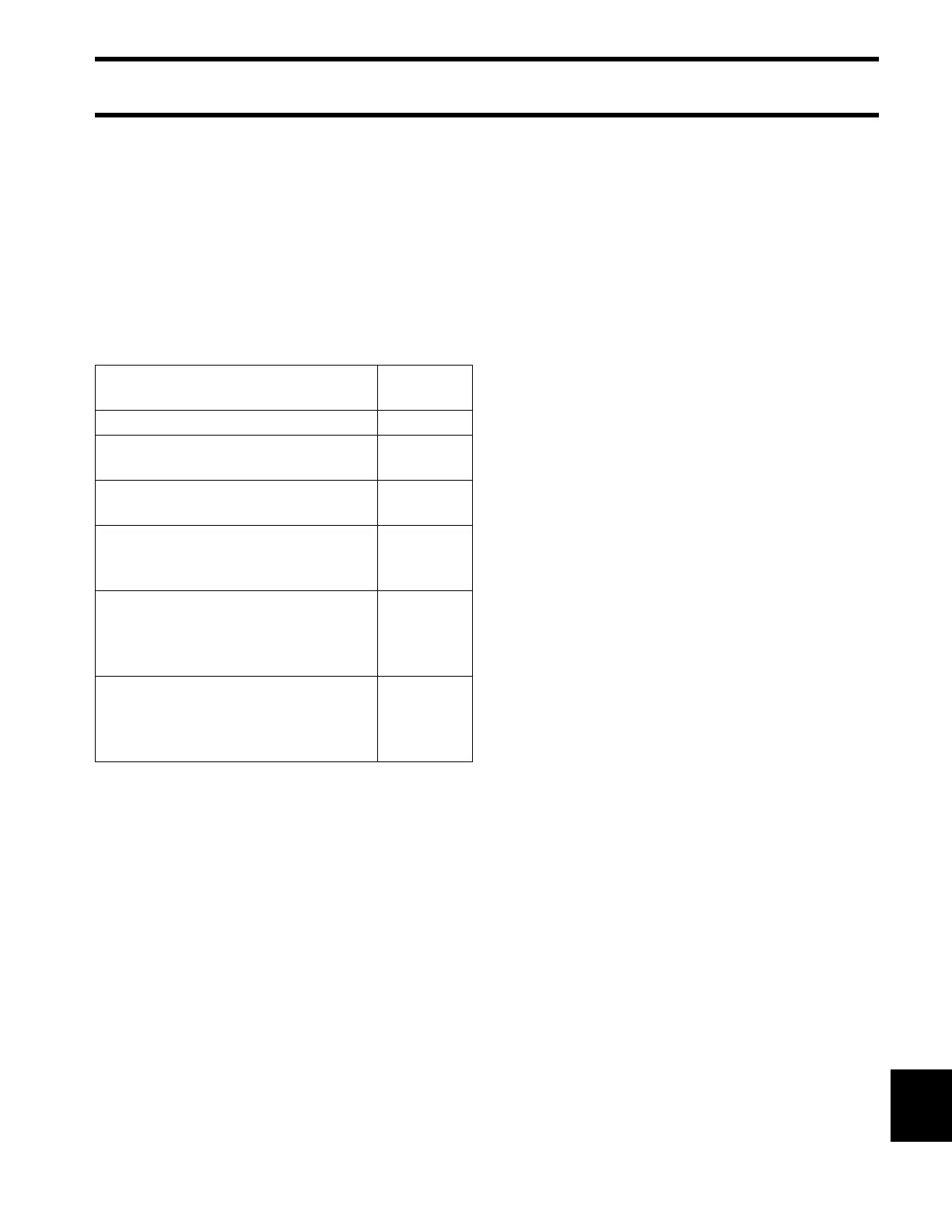

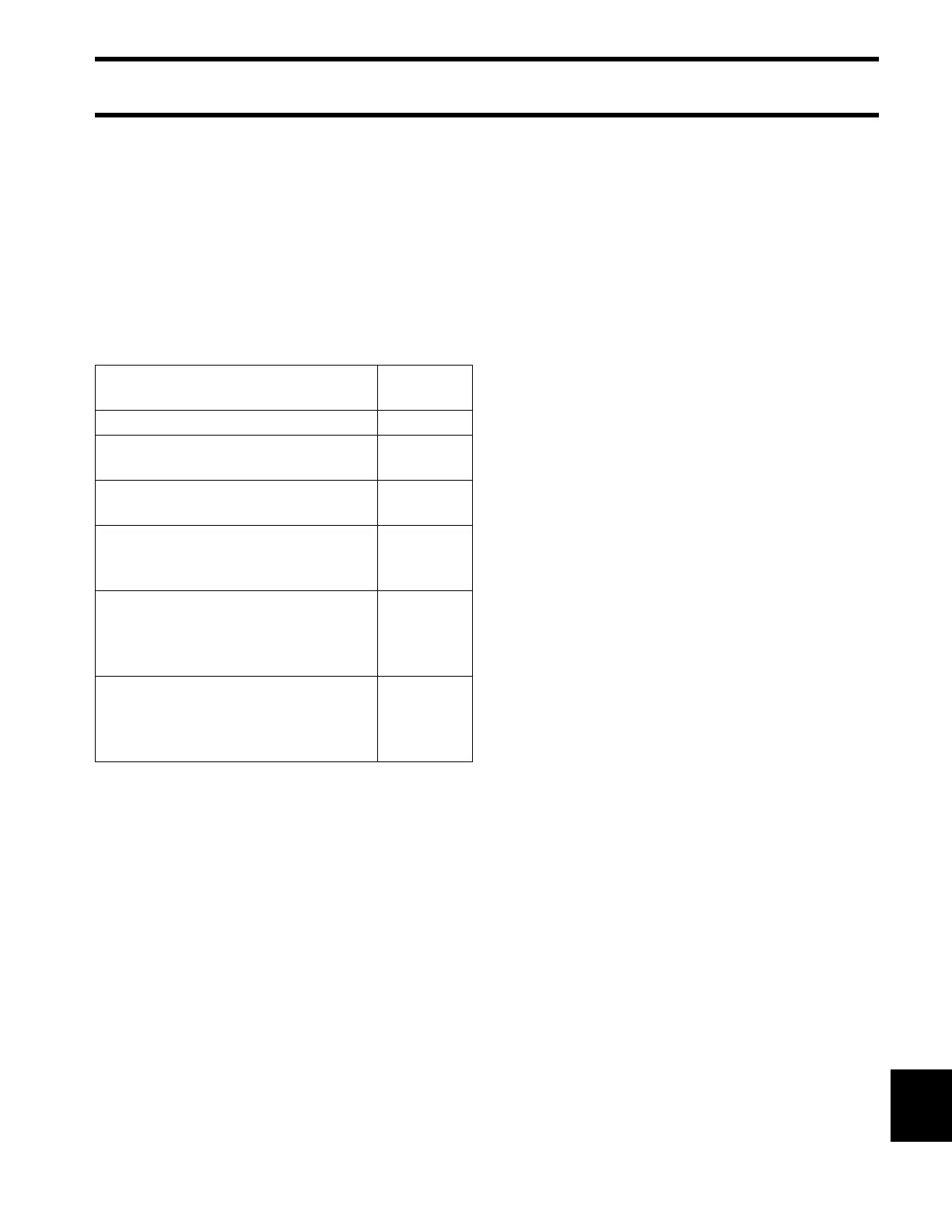

Symptoms Chart

If any of these symptoms describe the unit, follow

the ind icated Service Proce dures, in the o rder

listed, to locate and correct the problem.

Service Procedures

STEP 1

Be sure the manu al relea se valve is clo sed. If

NOT, torque to 45 to 55 in. lbs. (5.1 to 6.2 N·m).

STEP 2

Temporarily install a known good manual release

valve and r etest. If sympt oms rema in, origin al

valve is not the problem. Reinstall original valve.

If symptoms disap pear, t he origina l va lve wa s

faulty. Remove temp orary valve and replace with

correct new valve.

STEP 3

Go to TILT/TRIM RELA Y TEST on p. 105 to

determine if problem is power supply.

STEP 4

Remove trim mo tor a nd c heck condition of drive

coupling. If coupling is damaged, replace it.

STEP 5

Temporarily inst all a known go od pump ma nifold

assembly and retest. If symptoms remain, original

assembly is n ot the prob lem. Rein stall origina l

assembly.

If symptoms d isappear, the o riginal p ump mani-

fold assembly was faulty . Remove temporary

assembly and replace it with correct one.

STEP 6

Install replacement pump manifold assembly and

retest. If all symp toms are not corrected, reco n-

sider the problem using the new symptoms.

STEP 7

Install O-ring kit. Loo k for any cylinder damage.

Look for chip s in fluid or imp act valves. L ook for

other abnormal conditions. If all symptoms are not

corrected, reconsider th e problem using the new

symptoms.

Pressure Leakdown Test

Before servicin g a hydraulic unit, it should b e

pressure te sted to de termine the unit's malfunc-

tion. This test must be performed with the hydrau-

lic unit remo ved from the outboard and mounted

in a vise or holding fixture.

Power T rim/Tilt Service Kit, P/N 434524, allo ws

testing of trim/tilt operation and component condi-

tion.

• The “A” adapter, P/N 336658, checks operation

of the UP circuit.

Symptom

Service

Procedures

Unit will not move in either direction. 1, 2, 3, 4, 6

Unit runs slowly in one direction,

normal speed in other direction.

1, 2, 6

Unit runs slowly. (if low hours)

(if high hours)

1, 2, 7

1, 2, 5, 7

Unit leaks DOWN and/or will not

hold trim position against thrust in

forward.

1, 2, 6

Unit leaks both UP and DOWN –

Leaks down in tilt range and/or will

not hold trim position against thrust

in forward or reverse.

1, 2, 7

Unit will not trim/tilt one way, but

works the other way. Unit will not run

DOWN, but runs UP; or it runs

DOWN, but will not run UP.

2, 3, 6

Loading...

Loading...