Bucher Municipal

V Range

Routine Maintenance

155

V50 • V65 • V80 Operator’s Guide

(1) Water pump.

(2) Channel brush - (i) Grease when

renewing brush stock.

(3) Wide sweep brush - (i) Grease when

renewing brush stock.

(4) ‘Z’ drive gearbox and Fluid Coupling.

(5) Supawash hose reel.

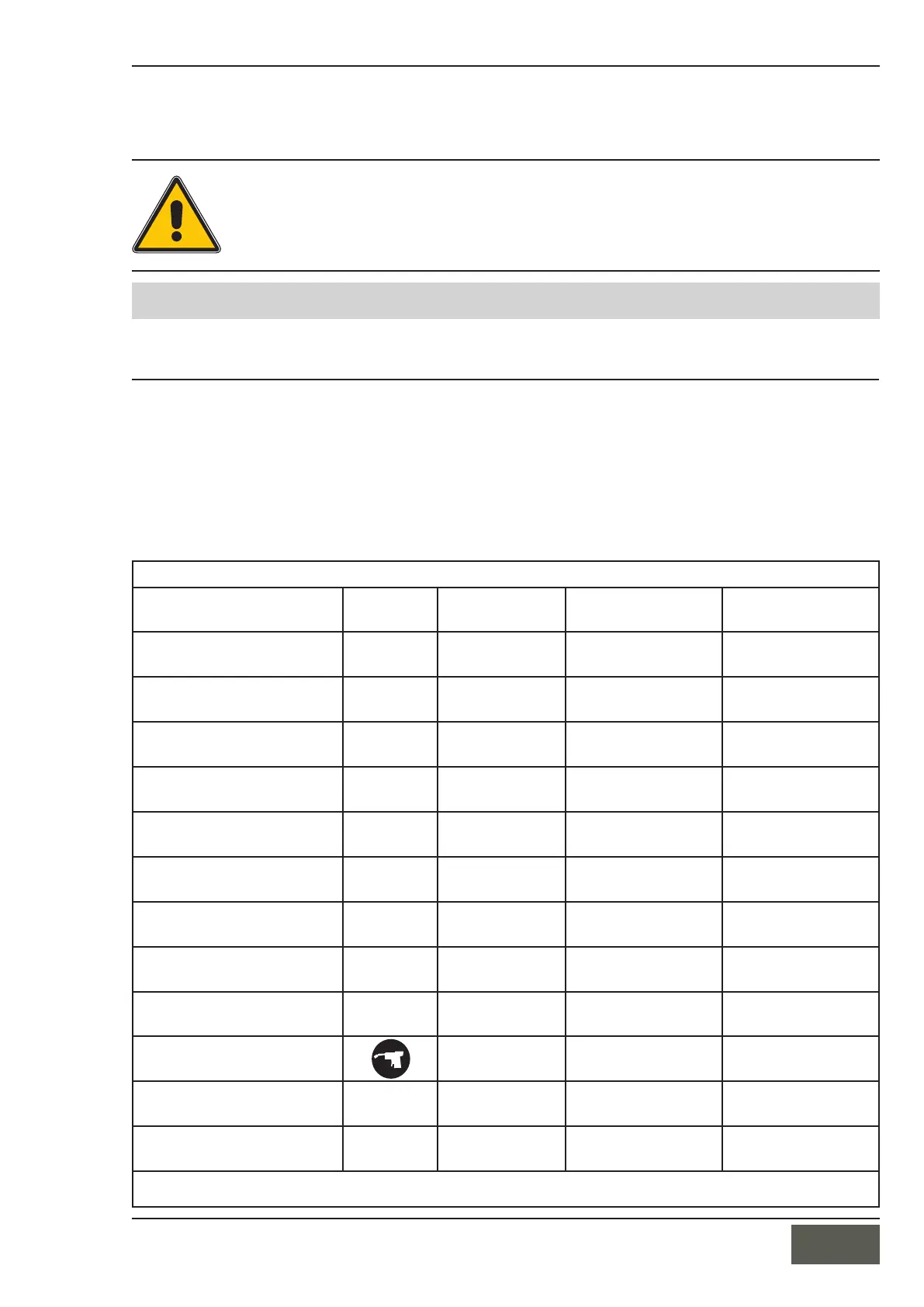

LUBRICATION DIAGRAMS

Refer to Maintenance Schedules for lubrication intervals

(6) Wanderhose - (i) Rotate boom to

distribute grease around bearing.

(7) Hopper tip pivot pin.

(8) Rear door.

(9) Nozzle wheel.

(10) Body raise cylinder.

Vt - Twin Engine

Approved Lubricants

Capacity ISO Oil Grade

Bucher Municipal

Part No.

Fuchs /

(**)

Klüber

(A) Hydraulic System 65L ISO 6743-4 HV 94-12

Renolin

B46 HVI

(B) Gearbox 2.5L API GL-4 / GL-5 94-67

Titan Cytrac

HSY 75W-90

(C) Supawash 0.37L API GL-4 / GL-5 94-67

Titan Cytrac

HSY 75W-90

(C) Powawash 3.8L SAE 85W-90 -

Renolin

212 / DTA220

(D) Fluid Flywheel 4.85L ISO 6743-4 HV 94-12

Renolin

B46 HVI

(E) Engine 14L

API CJ4

ACEA E6/E9

94-23

Titan Cargo

15W-40

(F) Drive Splines - - 94-24

Klüberpaste

46 MR 401**

(G) Antifreeze 15L - 94-21 Fricofrin HDD

(H) Chassis PAS - Auto

Gearbox

See Chassis

Handbook

- - -

Grease Points - 94-69 Renolit EP2

Auto-Lube - - 94-69 Renolit EP2

Battery Terminals - - -

Petroleum

Jelly

The above oils are those approved by Bucher Municipal. Other manufacturer’s oils must be of equivalent grade.

Item Description Item Description

WARNING

Ensure the machine is standing on firm, level ground and there are no obstructions above or

to the rear before raising the body.

Ensure the safety prop is engaged at all times when working under the body.

Loading...

Loading...