2 Technical description

6 720 646 864 (12/2010) – Technical guide Logano GE315, GE515 and GE615

17

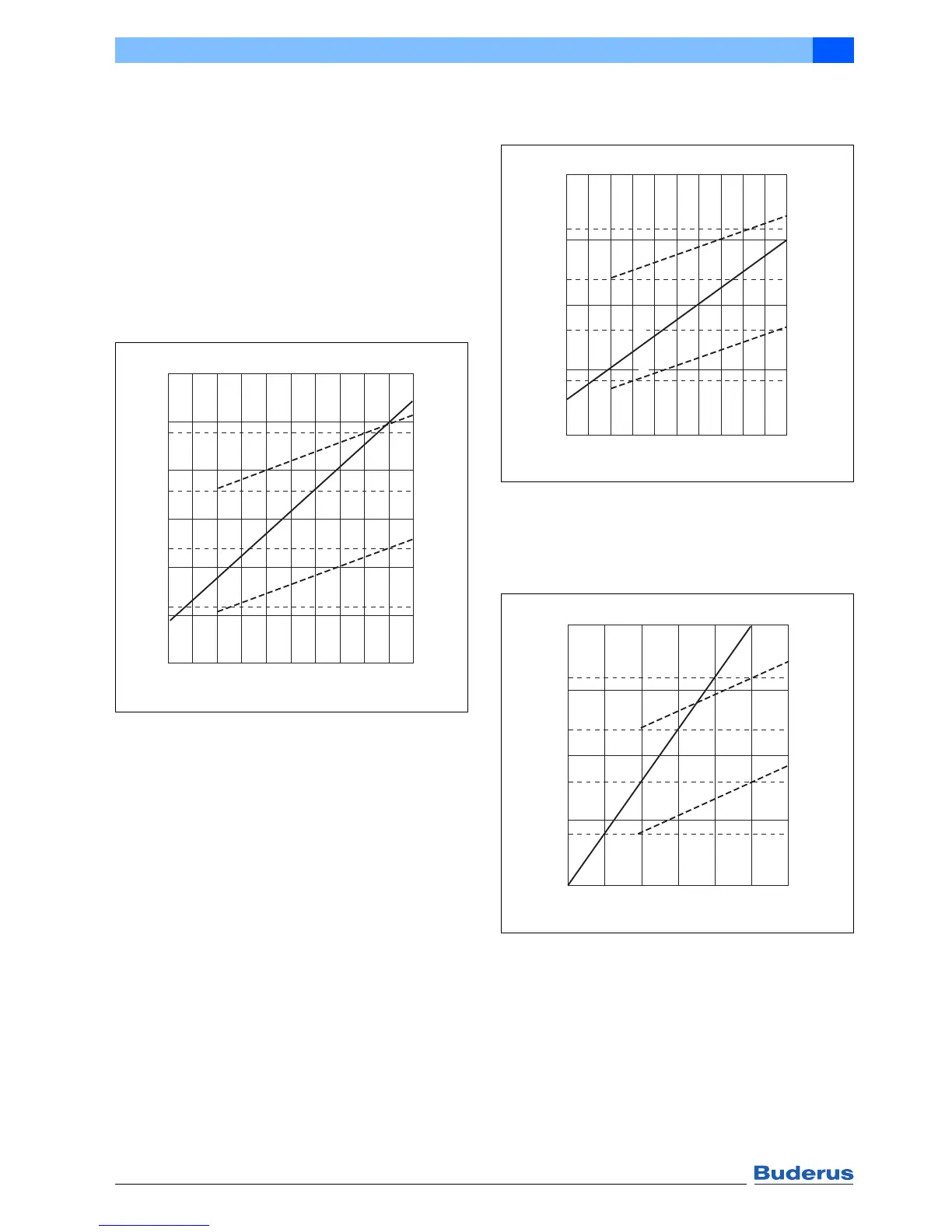

2.4.4 Standby loss and flue gas temperature

The standby loss is part of the rated heat input that is

required to achieve the specified boiler water

temperature.

The cause of this loss is the cooling down of the boiler

through radiation and convection during the standby time

(burner idle time). Radiation and convection result in part

of the output being transferred continuously from the

boiler surface to the ambient air. In addition to this surface

loss, the boiler can also cool down to a lesser degree

through the chimney draught.

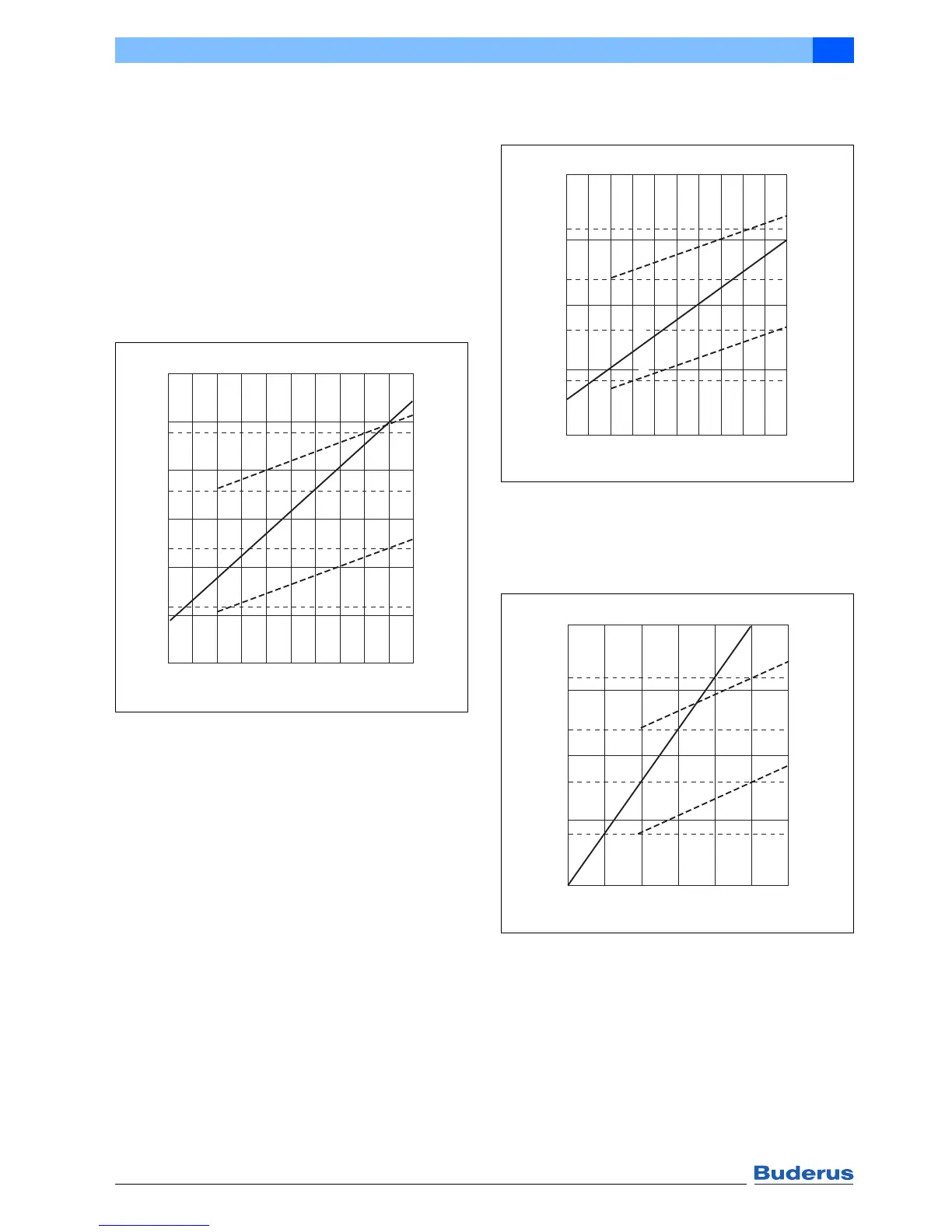

Logano GE315

Fig. 18 Standby loss and flue gas temperature of the

Ecostream cast iron boilers and Ecostream cast

iron boiler units Logano GE315, subject to the

average boiler water temperature

Key to Fig. 18, Fig. 19 and Fig. 20:

ϑ

A

Flue gas temperature

ϑ

K

Average boiler water temperature

q

B

Standby loss

a

1

Flue gas temperature at stage 1

(partial load here approx. 60 % of rated output)

a

2

Flue gas temperature at stage 2, full load

b Standby loss

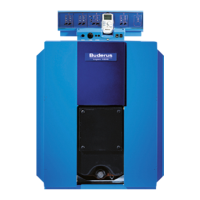

Logano GE515

Fig. 19 Standby loss and flue gas temperature of the

Ecostream cast iron boilers and Ecostream cast

iron boiler units Logano GE515, subject to the

average boiler water temperature

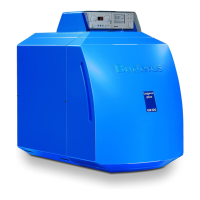

Logano GE615

Fig. 20 Standby loss and flue gas temperature of the

Ecostream cast iron boilers and Ecostream cast

iron boiler units Logano GE615, subject to the

average boiler water temperature

8035

30

0

0,1

0,2

0,3

0,4

0,5

0,6

40

45 50 55 60 65 70 75

200

180

160

140

120

ϑ

A

[°C]

ϑ

K

[°C]

q

B

[%]

6 720 644 097-17.1il

a

2

b

a

1

80

30

0

0,2

0,1

0,3

0,4

40

45 50 55

120

140

160

180

200

60 65 70 75

q

B

[%]

ϑ

A

[°C]

35

6 720 644 097-18.1il

a

2

b

a

1

ϑ

K

[°C]

80

20

0

0,05

0,10

0,15

0,2

30 40 50 60 70

200

180

160

140

120

a

2

b

a

1

6 720 644 097-19.1il

q

B

[%]

ϑ

A

[°C]

ϑ

K

[°C]

Loading...

Loading...