4 Regulations and operating conditions

6 720 646 864 (12/2010) – Technical guide Logano GE315, GE515 and GE615

22

4.2 Pressure Equipment Directive (PED)

and Health & Safety at Work Act

4.2.1 Application area

The Pressure Equipment Directive applies to safety

temperatures > 110 °C, i.e. a boiler equipped with a high

limit safety cut-out for 110 °C is excluded from applying

the Pressure Equipment Directive and from the Health &

Safety at Work Act [Germany].

4.2.2 Boiler classification

The Pressure Equipment Directive has four categories,

graded according to the pressure/volume product.

Depending on their size, the boilers are classified into

these four categories.

4.2.3 Initial and repeat inspections

The revised Health & Safety at Work Act [Germany],

passed on 3 October 2002 and applicable to hot water

and steam boiler systems as of 1 January 2003, specifies

much more demanding requirements, particularly for

category III and category IV boilers.

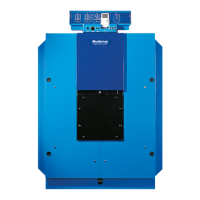

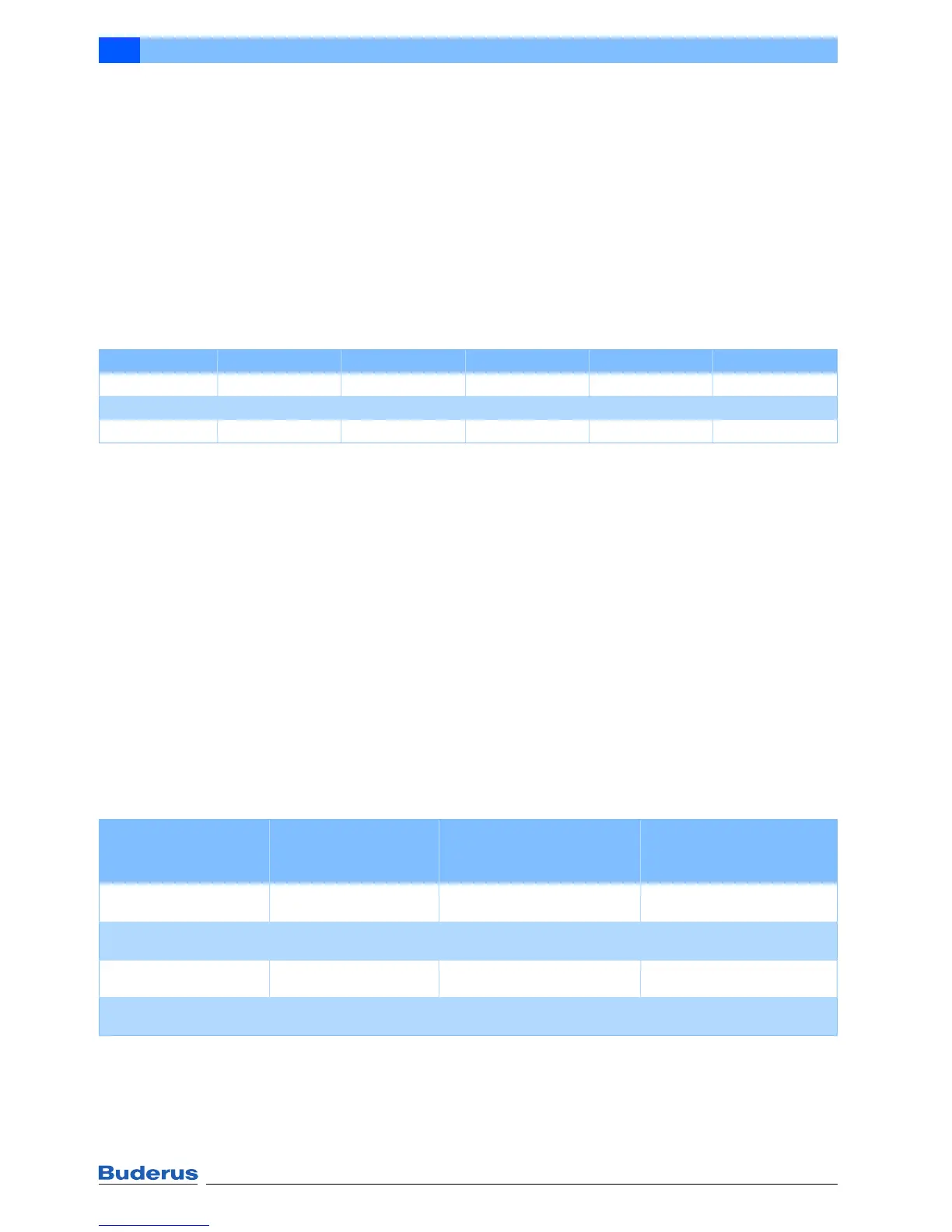

4.2.4 Boiler category classification according to Pressure Equipment Directive 97/23/EC

z Applicable

– N/A

4.2.5 Health & Safety at Work Act regarding steam and hot water boilers

Reservation with regard to granting permission

(paragraph 13 BetrSichV) [Germany]

Assembly, installation and the operation of category IV

boilers require permission from the relevant authority

[Germany].

Inspection prior to commissioning

(paragraph 14 BetrSichV)

• Boilers in categories I and II can be inspected in situ,

i.e. as part of the system, by a competent person

(master heating system builder).

• Boilers in categories III and IV must be checked by an

authorised supervisory body in situ, i.e. as part of the

system, prior to commissioning.

Repeat inspections (paragraph 15 BetrSichV)

Boilers in category III with a pressure/volume product

p × V greater than 1000 and boilers in category IV must

be inspected on a repeat basis:

• External inspection after no more than a year

• Internal inspection after no more than three years

• Strength tests after no more than nine years

The inspection intervals should be determined by the

system operator based on a technical safety assessment.

4.2.6 Overview of the Health & Safety at Work Act [Germany]

z Required – Not required

Logano Category I Category II Category III p × V > 1000 Category IV

GE315 ––Allz –

GE515 – – All z –

GE615 ––––All

Tab. 8 Boiler category classification according to Pressure Equipment Directive 97/23/EC

Reservation with regard

to granting permission

Paragraph 13

Inspection prior to

commissioning

Paragraph 14

Repeat inspections

Paragraph 15

Category I and II boilers

(up to 200 bar × litres)

– z

1)

–

Category III boilers

(up to 1000 bar × litres)

– z –

Category III boilers

(> 1000 bar × litres)

– z

2)

z

2)

Category IV boilers

(> 3000 bar × litres)

z z

3)

z

3)

Tab. 9 Overview of the Health & Safety at Work Act [Germany]

1) May be carried out by a competent person

2) Logano GE315 and GE615

3) Logano GE615

Loading...

Loading...