2 Technical description

6 720 646 864 (12/2010) – Technical guide Logano GE315, GE515 and GE615

6

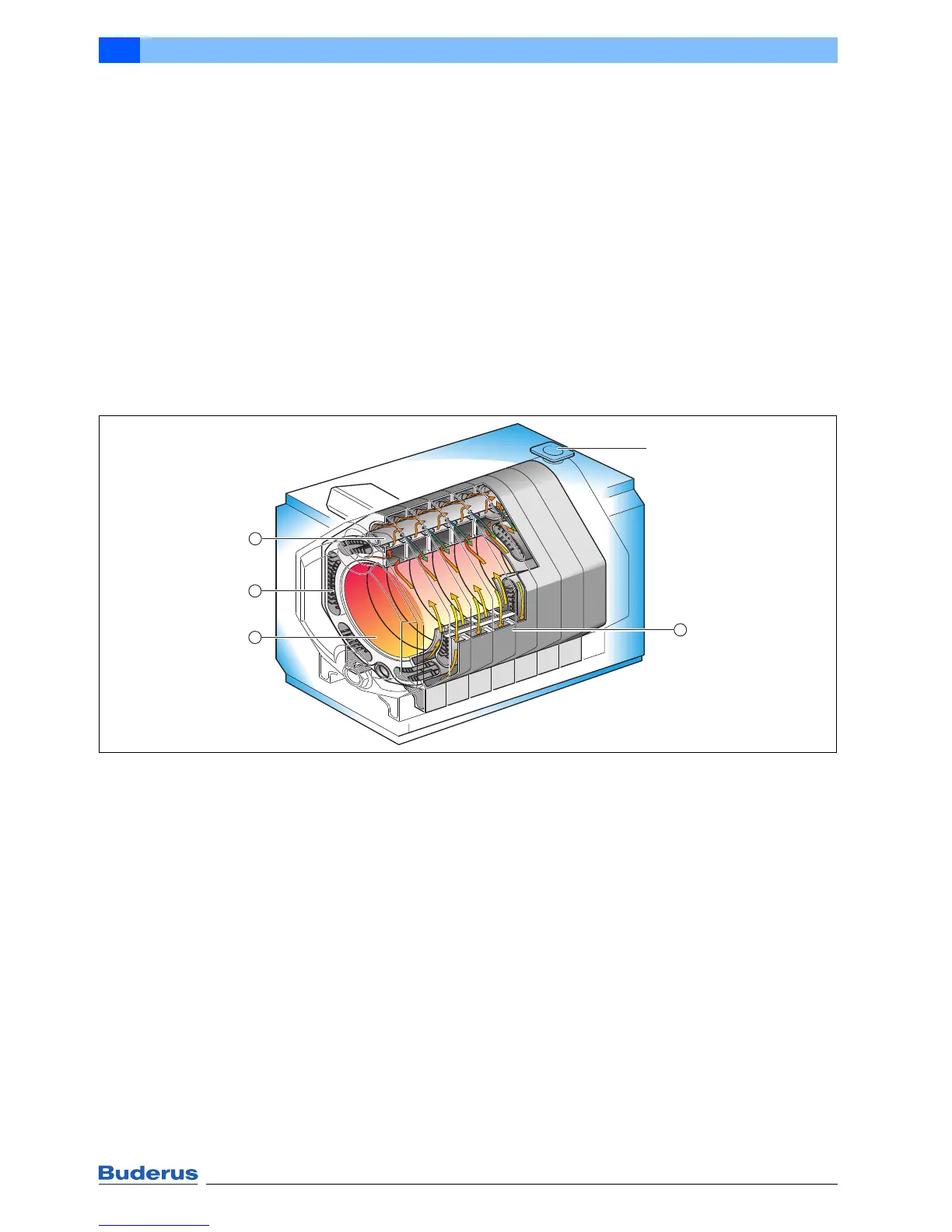

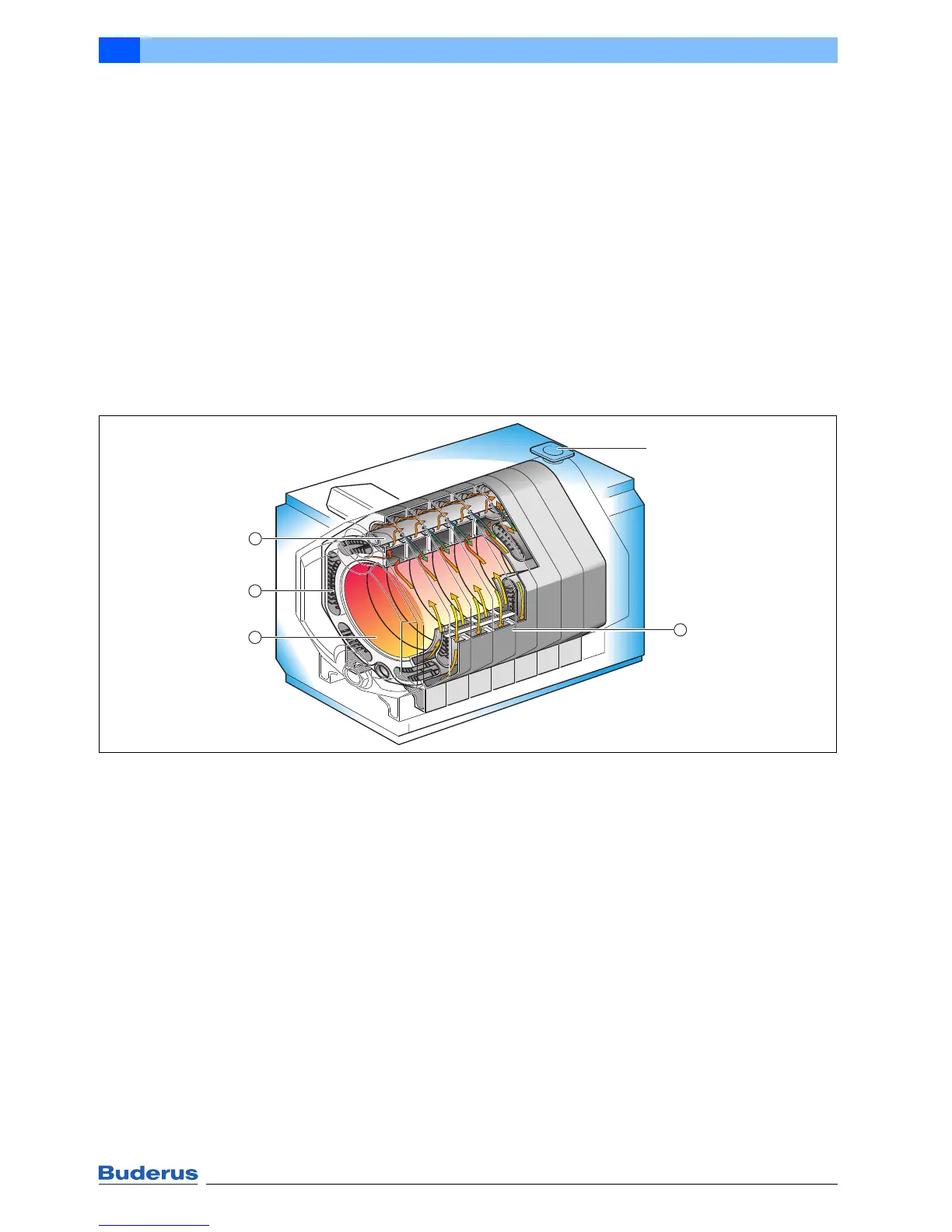

2.2 Thermostream technology of the Ecostream cast iron boilers

2.2.1 Function principle

Thermostream technology is based on the mixing of cold

return water with hot flow water inside the boiler. Return

temperature raising takes place in the upper section of the

boiler. The return water therefore reaches a higher

temperature level before it flows to the heating surfaces.

A thermal shock to the heating surfaces is consistently

prevented, even if there is a sudden inflow of cold return

water.

No additional measures are required to raise the return

temperature or maintain a minimum flow rate under certain

operating conditions.

In steady operation, the surface temperatures on the hot

gas side are above the dew point of the hot gases. No

condensate is formed in the combustion chamber or

secondary heating surfaces. As a consequence,

corrosion inside the boiler is prevented.

The combustion chamber and heating surfaces receive a

flow of boiler water through natural circulation, and they

continually extract heating energy from the hot gas flow.

This results in high energy utilisation, stable operating

characteristics and simple hydraulic connections.

Thermostream technology means the boiler is

constructed with single-skin direct heating surfaces,

making it extremely compact.

Fig. 2 Thermostream technology taking the Ecostream cast iron boiler Logano GE515 as an example

VK Boiler flow

1 Boiler section with heating water channels

2 Combustion chamber

3 Secondary heating surfaces

4 Feed pipe for return water

6 720 644 097-01.1il

VK

1

2

3

4

Loading...

Loading...