7 Systems

6 720 646 864 (12/2010) – Technical guide Logano GE315, GE515 and GE615

54

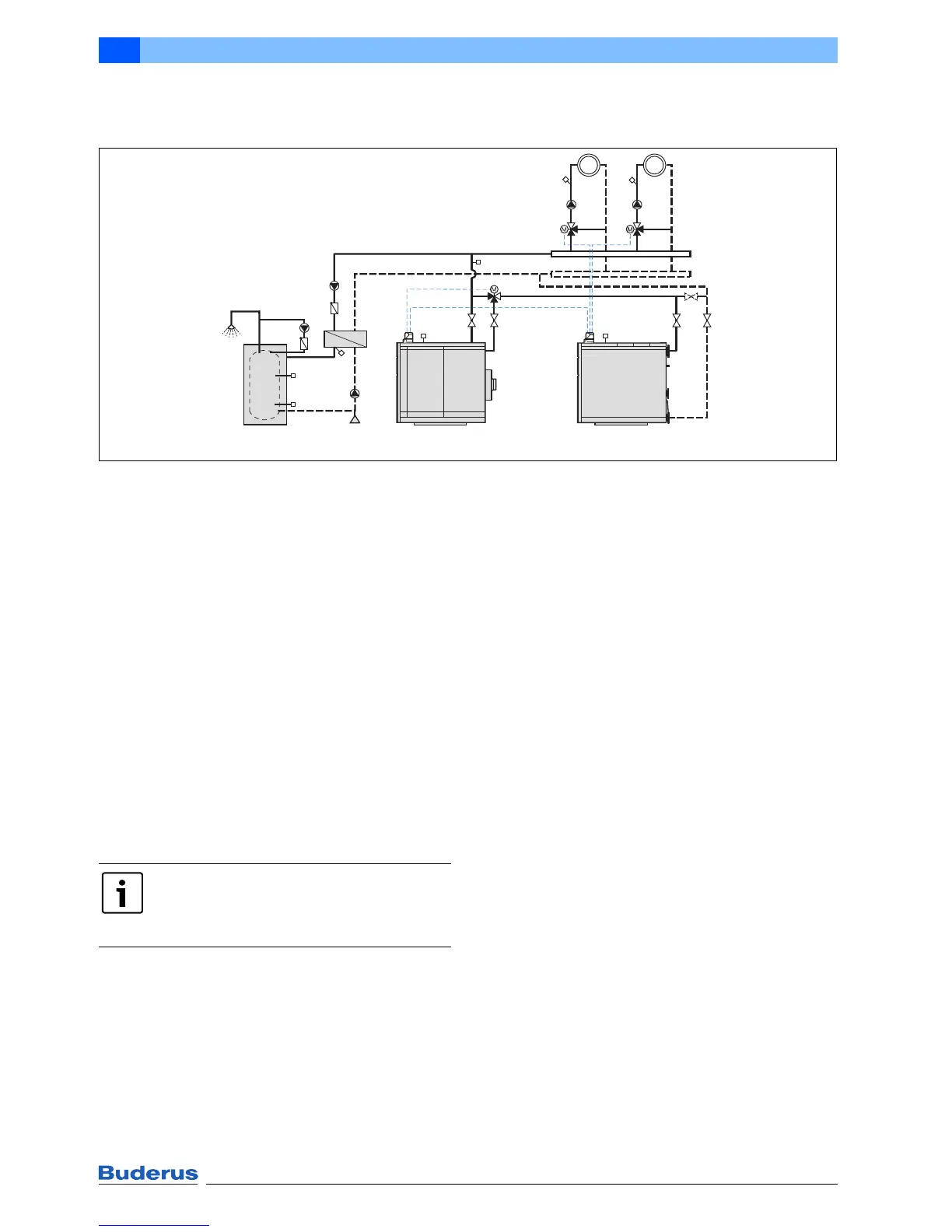

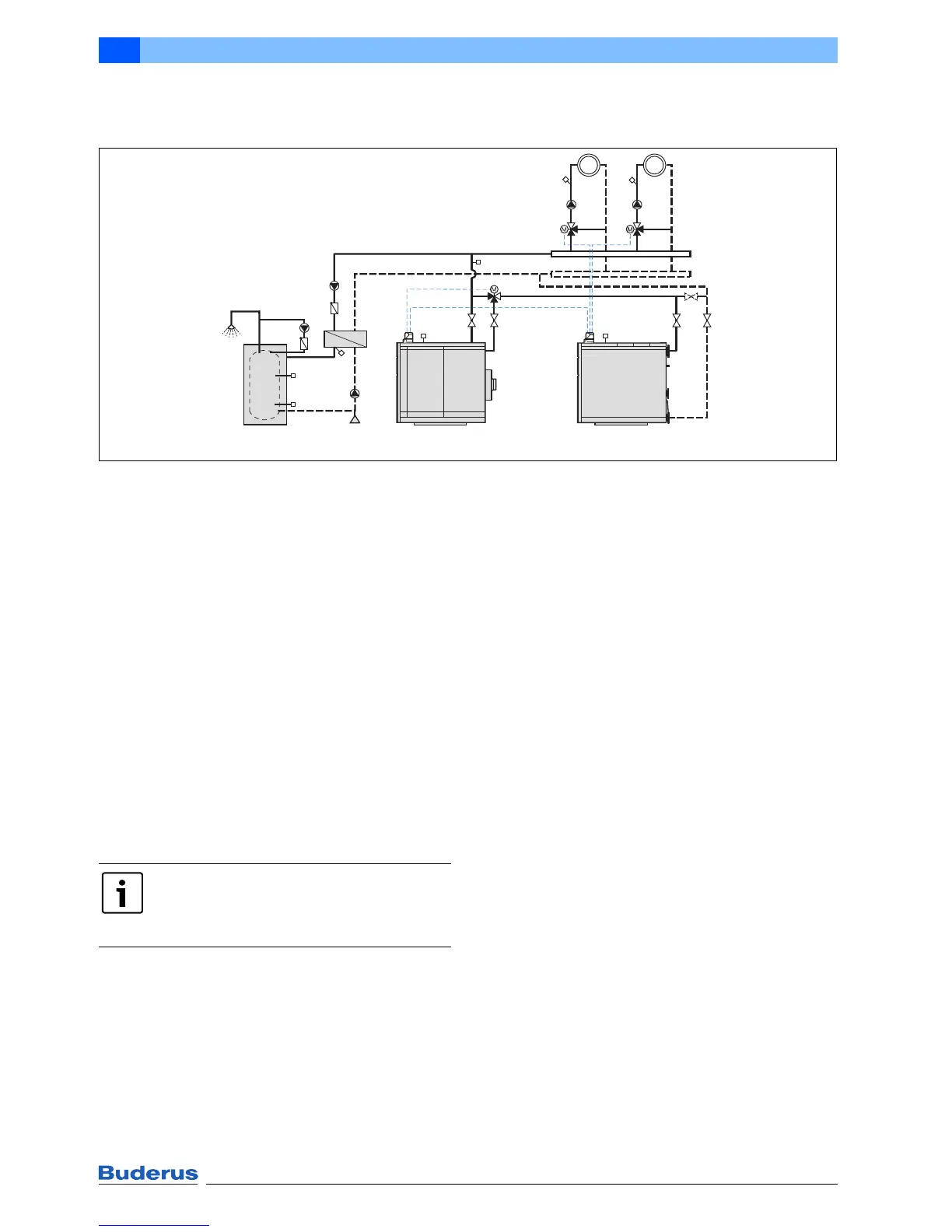

7.10 2-boiler system Ecostream cast iron boiler/gas condensing boiler with boiler

control and heating circuit control

Fig. 40 System example for an Ecostream cast iron boiler and a Logano plus SB315 or SB615 gas condensing boiler;

DHW heating with primary store system; number and version of the heating circuits dependent on the control

unit

EK Cold water inlet

FK Boiler water temperature sensor

FV Flow temperature sensor

FVS Strategy flow temperature sensor

FW DHW temperature sensor

HK Heating circuit

KR Check valve

PH Heating circuit pump

PS Cylinder primary pump

PW Stratification pump

PZ DHW circulation pump

RK Return

RK1 Low temperature return to condensing boiler

SH Heating circuit actuator

SK Boiler circuit actuator

VK Boiler flow

WT Heat exchanger

1 Gas condensing boiler

2 Primary store system (DHW cylinder as option)

1)

Inspection bypass (optional)

Application area

• Logano plus SB315 and SB615 gas condensing

boilers

• Ecostream cast iron boilers Logano GE315, GE515

and GE615

• Boiler circuit control with the Logamatic 4211 and

4312 control units, also in conjunction with third party

heating circuit control or special applications

Function description

The boiler sequence can be controlled via the multi boiler

strategy module subject to load and time. If the

temperature at the strategy sensor FVS falls below the set

flow temperature, the (1) lead boiler starts. If the heat

demand increases, the Logano (2) lag boiler is

automatically switched on.

When the operating flow temperature at temperature

sensor FK2 for the lag boiler is reached, the boiler circuit

actuator SK opens in the flow direction of the Ecostream

cast iron boiler and the entire flow rate is routed via the

Ecostream cast iron boiler. If the load falls, the switching

processes run in reverse order.

Special design information

• The boiler sequence cannot be reversed.

• Size the heating circuit pumps in accordance with the

maximum calculated pressure drop in the heating

circuit and boiler circuit (sum of the pressure drop

levels on the water side of both boilers). The pressure

drop levels of both boilers must be reliably overcome.

Alternatives for hydraulic circuits if the pressure drop

on the water side is too high are available on request.

• To keep the pressure drop on the water side low, when

sizing the heating circuits maintain a minimum spread

of 20 K.

• We recommend distributing the total output between

the boilers so each has 50 %.

• Design the connections in such a way that the boilers

can be separated, independently of each other, to

ensure an emergency supply during maintenance work.

HK2HK1

SK

1)

SH2

PH2

SH1

PH1

FK2

FK1

VK

RK1

VK RK

FVS

FV1 FV2

6 720 644 097-34.1il

Logano (2)

1 (1)

2

KR

PS

PW

FW2

KR

PZ

FW3

FW1

EK

WT

The circuit diagram is only a schematic

illustration!

For information on all system examples,

Æ page 36.

Loading...

Loading...