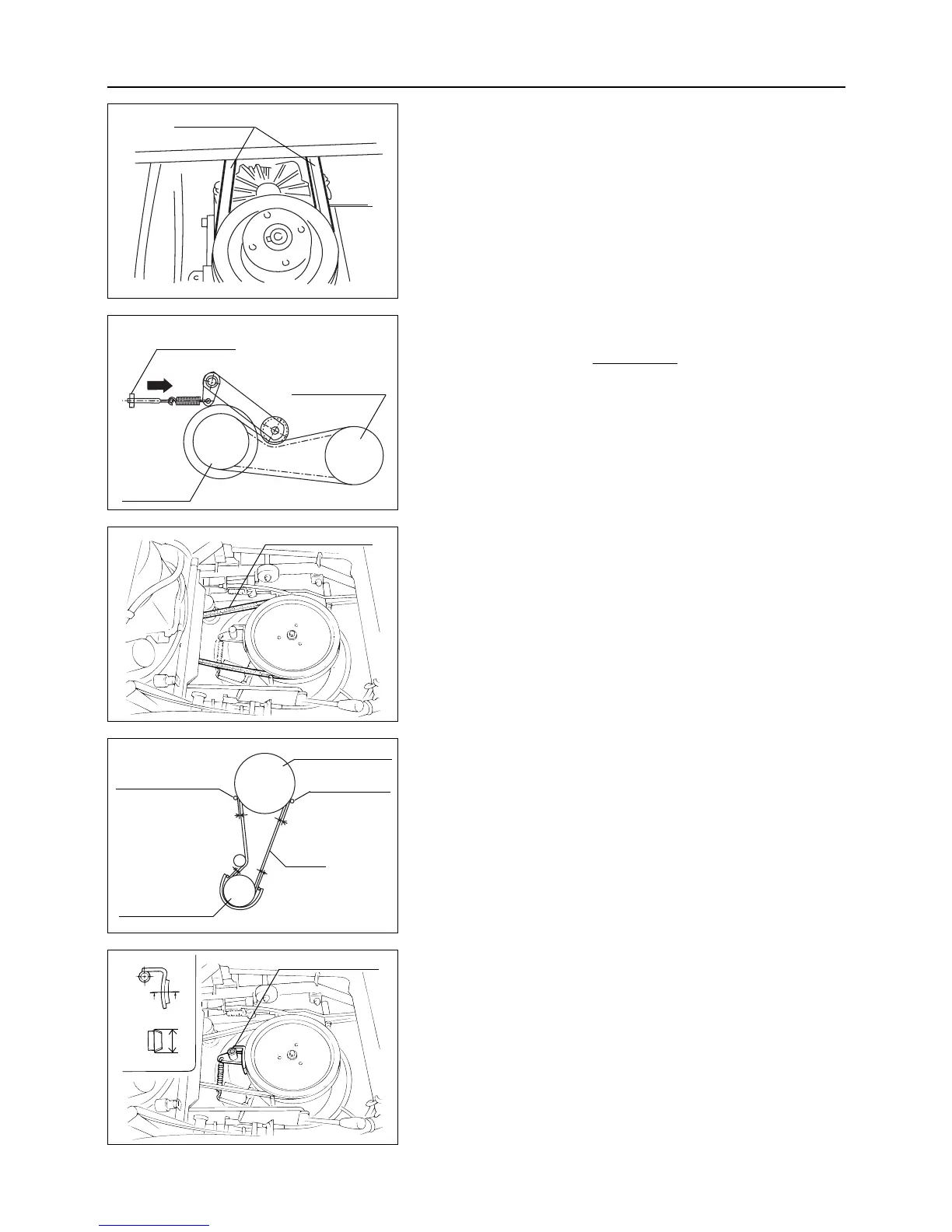

Adjusting

Adjust drive belt only when it slips during driv-

ing. Drive belt should always be in tension dur-

ing operation.

1. To adjust drive belt, turn adjusting nut in direction A.

7.8.2 Rotary Drive Belt

Inspecting

1. Visually check rotary drive belt for damages. If any dam-

age is found, replace rotary drive belt.

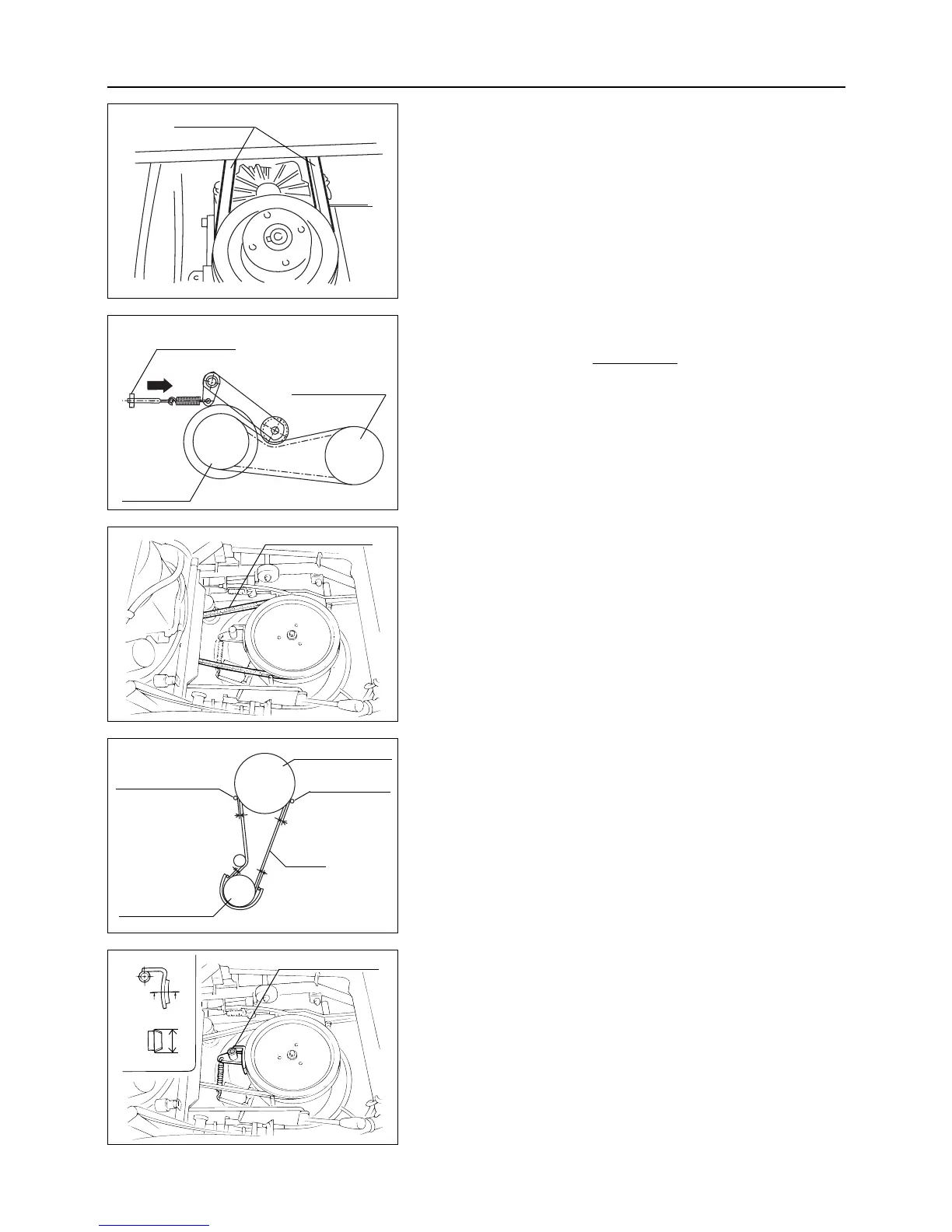

Adjusting

After replacing rotary drive belt, make adjustment as follows :

1. On engine-side, set the clearances on belt stoppers A

between 2 and 4 mm and B approximately 10 mm.

2. Set the clearance between rotary belt holder and rotary

drive belt between 3 and 5 mm (when belt slips out of

rotary, check the clearance on belt holder at rotary side).

– 43 –

7

Maintenance

7.8 Adjusting

7.8.1 Drive Belt

Inspection

1. Visually check drive belt for damages. If any damage is

found, replace drive belt.

7.8.3 Rotary Brake

Inspecting

1. Examine if rotary stops within 4 seconds after moving

rotary clutch lever to [OFF] position. If rotary does not

stop within 4 seconds, inspect rotary brake lining for

wear. If the height of lining is 20 mm or less, consult

your dealer to replace it.

Drive belt

A

Engine pulley

Adjusting nut

HST pulley

Rotary drive belt

Rotary belt holder

Engine pulley

V belt

3-5mm

A

B

3-5mm

20

Rotary belt holder

Cutting blade pulley

Rotary brake

Loading...

Loading...