53

ENG

pCO5plus +0300020EN rel. 1.2 - 07.11.2013

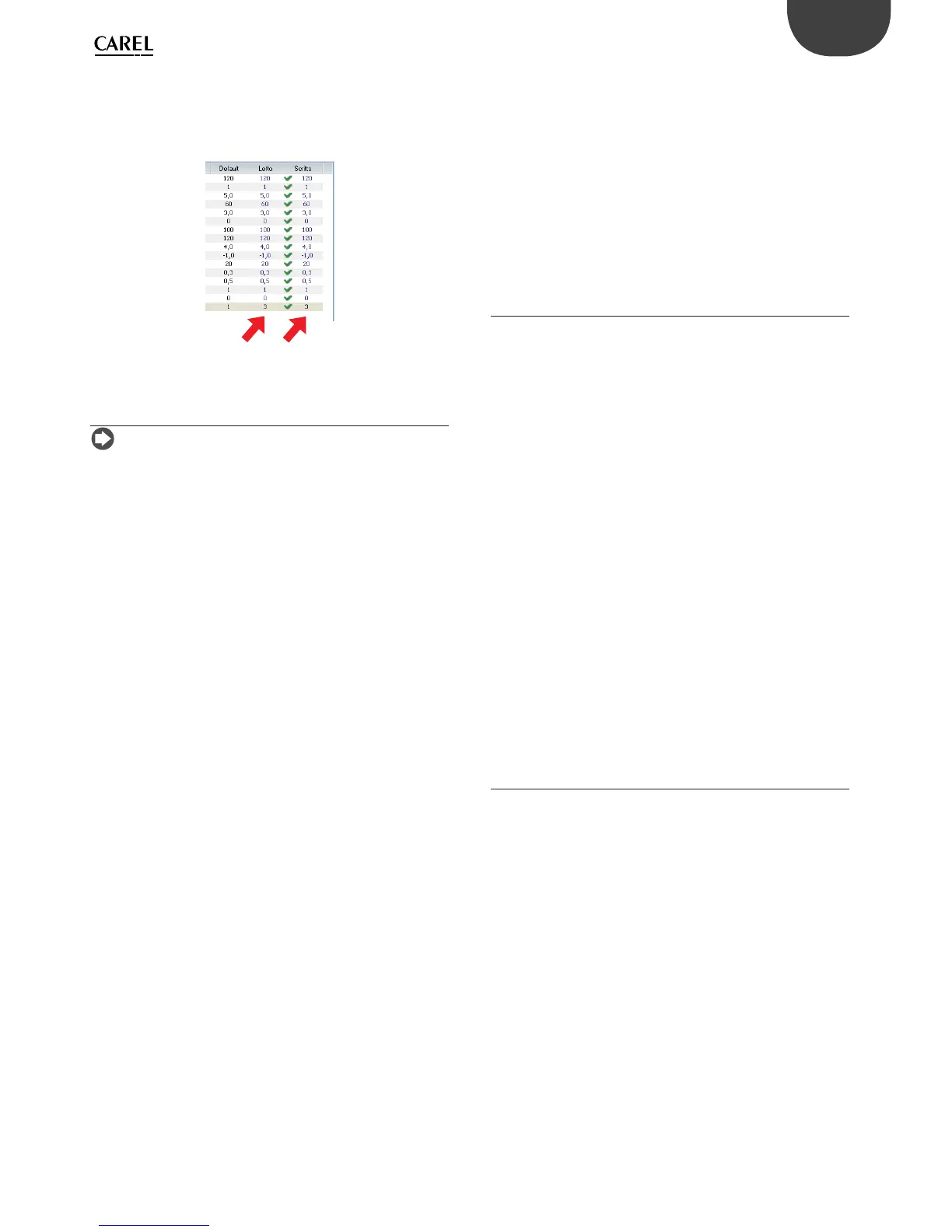

2) Enter the new value (e.g. 3) and click OK. The new value will appear in

the col

umn marked “scritto” [written]. To write the parameter to the pCO

controller, right-click and select “scrivi selezionate” [write selected]. The

new value will appear in the column marked “scritto” [written], meaning

that the parameter has been written to the controller.

Fig. 9.j

Click on “Salva” [Save] to generate the project’s “.2cw” fi le.

Commissioning: basic concepts

Note: The following paragraphs are from the online help of pCO

Manager, to which the user is referred for further details.

Commissioning is a confi guring and real-time monitoring software that

can be used to supervise the performance of an application program

installed on a pCO, to start up the pCO and to perform debugging and

maintenance.

With this software the user can set the confi guration parameters, edit the

values of volatile and permanent variables, save on fi le the trends of the

unit’s main quantities, manually manage the unit’s I/O using simulation fi les

and monitor/reset the alarms of the unit on which the device is installed.

Work carried out with Commissioning is preceded by confi guring the work

environment, which is typically done by the project designer. The active

project in 1Tool is automatically loaded by pCO Manager.

The project designer can use the confi guration functions of Commissioning

to decide which variables should be subjected to monitoring, logging,

trend-monitoring and event-monitoring, to organize variables into

categories and to create sets of confi guration parameters.

Operators using Commissioning for maintenance will be able to see the

necessary variables and to draw from preset confi guration values.

Support les

Once the design of the application is completed, 1Tool generates a

number of fi les in the compiling stage, two of which are required by

Commissioning:

• <nomeApplicativo>.2CF [<ApplicationName>.2CF] (variable descriptor)

• <nomeApplicativo>.2CD [<ApplicationName>.2CD] (category and

access profi le descriptor)

In addition to these fi les, the software also manages the <nome

applicativo>.DEV [<Application Name>.DEV] fi le, which contains the unit’s

preset parameters.

When the user has fi nished using Commissioning, whether for confi guration

or monitoring purposes, the following fi les can be generated:

• <nomeApplicativo>.2CW [<ApplicationName>.2CW] (descriptor for

categories, access profi les, monitoring groups)

• <nomefi leCommissioningLog>.CSV [<FilenameCommissioningLog>.

CSV] (fi le used for the commissioning log, containing data of the

variables logged during monitoring)

Therefore, to confi gure Commissioning the following fi les are required: .2CF,

2CD and, if necessary, the .DEV fi le, which can be imported or exported.

For monitoring purposes, in addition to the fi les above, it might also be

necessary to have the .2CW fi le, containing the defi nition of the work

environment. The commissioning log fi le is a simple output fi le.

pCO Load: basic concepts

pCOLoad is the module that manages:

• uploading to the fl ash memory (of the device or of the ProgKeyX key

installed on the pCO);

• uploading to the NAND memory of certain devices;

• downloading the log fi le, .DEV fi le and P memory (from the fl ash

memory);

• downloading fi les from the NAND memory, if present.

The fi les exchanged with the Flash memories of pCO controllers are:

• BOOT.BIN (download reserved, upload enabled from menu)

• BIOS.BIN (download reserved)

• <nomeApplicativo>.BLB [<ApplicationName>.BLB] (download

reserved)

• <nomeApplicativo>.BIN [<ApplicationName>.BIN] (download reserved)

• <nomeApplicativo>.DEV [<ApplicationName>.DEV]

• <nomeApplicativo>.GRT [<ApplicationName>.GRT] (upload only, from

which the .GRP fi le is extracted)

• <nomeApplicativo>.IUP [<ApplicationName>.IUP]

• <nomeApplicativo>.LCT [<ApplicationName>.LCT]

• <nomeApplicativo>.PVT [<ApplicationName>.PVT]

• <nomepCOlog>.BIN, <nomepCOlog>.CSV, <nomepCOlog_GRAPH>.

CSV [<pCOlogName>.BIN, <pCOlogName>.CSV, <pCOlog_

GRAPHName>.CSV] (only if log fi les have been confi gured, download

only).

The fi les exchanged with the NAND memories of pCO controllers are:

• any fi le that the pCO can independently copy to the fl ash memory (see

above list);

• external fi les (e.g. .pdf or .doc fi les for documentation).

LogEditor: basic concepts

LogEditor is the module used to confi gure the log fi les of pCO devices

(pCO logs). Confi guring pCO logs consists in defi ning a number of sets

of variables in which to specify which variables should be logged, the

logging method (by frequency or by event) and the minimum number

of loggings required. Confi guration is based on a binary fi le (.PVT – Public

Variable Table), which is generated by 1Tool and contains the descriptive

data of the variables that can be logged.

All the log confi gurations so defi ned are saved in the .LCT (Log

Confi guration Table) binary fi le, which must be uploaded to the pCO

together with the .PVT fi le. Log confi guration data is also saved in a fi le

that can be used only by LogEditor – the .LEF fi le, which must be saved to

be edited with LogEditor as necessary.

LogEditor can be used even when the device is not connected.

Once the fi les for logging are uploaded to the pCO, the pCO

saves the logged data in the following fi les:

• .BIN fi le containing all the data in binary format;

• .CSV fi le containing the same data in a generic format with values

separated by commas;

• *_GRAPH.CSV containing the same data to be used for charting purposes

Loading...

Loading...