22

Warning! Operating the equipment incorrectly can cause serious injury and

damage. Do not use the functions described here until you have read and com-

pletely understood all of the following documents:

- these Operating Instructions

- all "Operating Instructions" for the system components, especially the

"Safety rules"

Please see the section headed “The Set-up menu: Level 1” for information on the set-

tings, setting range and units of measurement of the available parameters.

Symbol Explanation

GPr Gas pre-flow time

I

S

Starting-current phase: The temperature is raised gently, at low welding

amperage, so that the filler metal can be positioned correctly

t

up

Upslope phase: The starting current is continuously increased, until it

reaches the welding amperage

I

1

Welding-current phase: Uniform thermal input into the base metal, whose

temperature is raised by the advancing heat

I

2

Reduced-current phase: Intermediate lowering of the welding amperage, in

order to prevent any local overheating of the base metal

t

2

Downslope phase: The welding current is continuously lowered, until it

reaches the final current.

I

E

End-crater (final-current) phase: To prevent any local overheating of the

base metal due to heat build-ups towards the end of welding. This eliminates

any risk of weld drop-through.

SPt Spot-welding time

G-H/G-L Gas post-flow time

G-H Gas post-flow time at maximum welding amperage

G-L Gas post-flow time at minimum welding amperage

Symbols and

their explanati-

ons

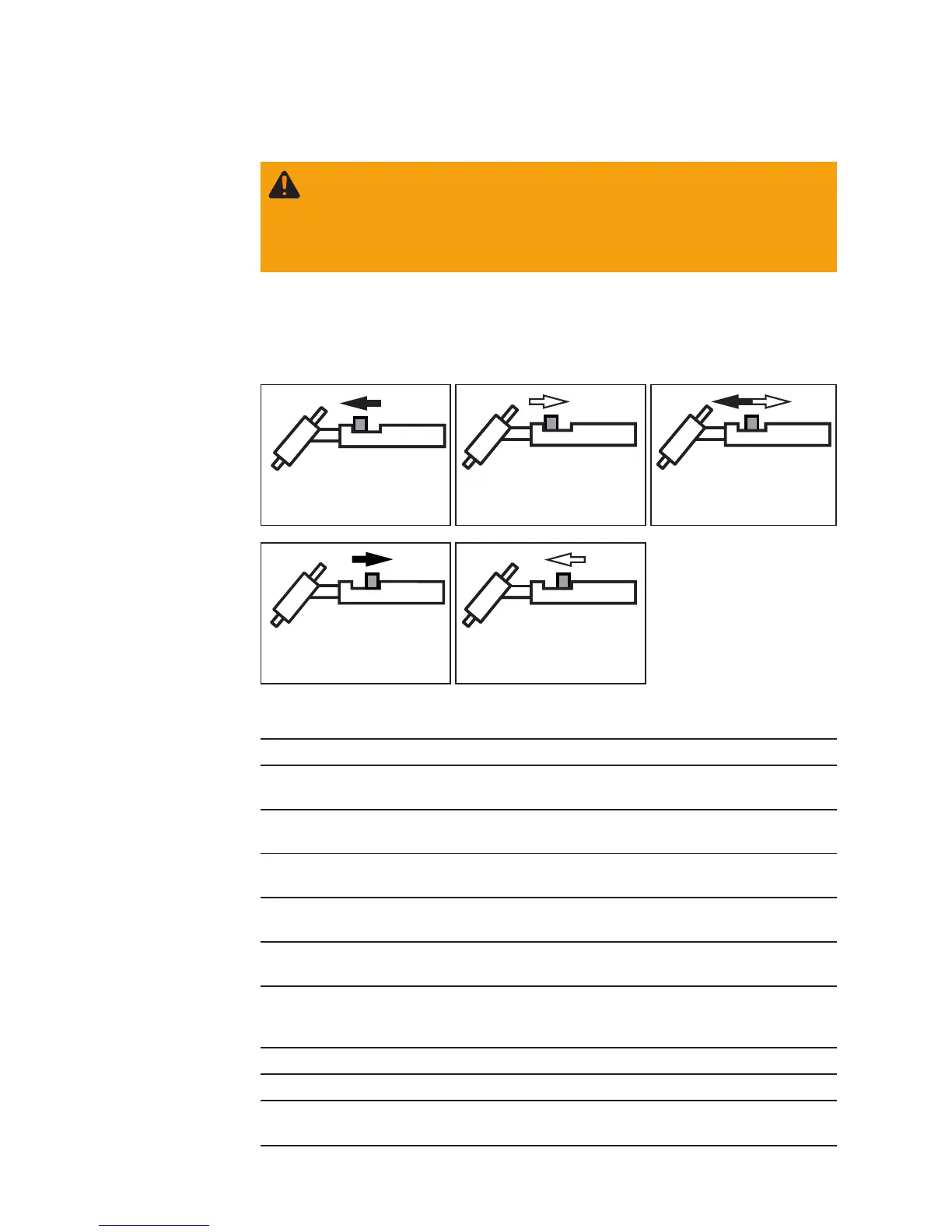

Push forward and hold the

torch trigger

Release the torch trigger Briefly push forward the

torch trigger (< 0.5 s)

Pull back and hold the

torch trigger

Release the torch trigger

TIG operating modes

General remarks

Loading...

Loading...