32

To ignite the arc, proceed as follows:

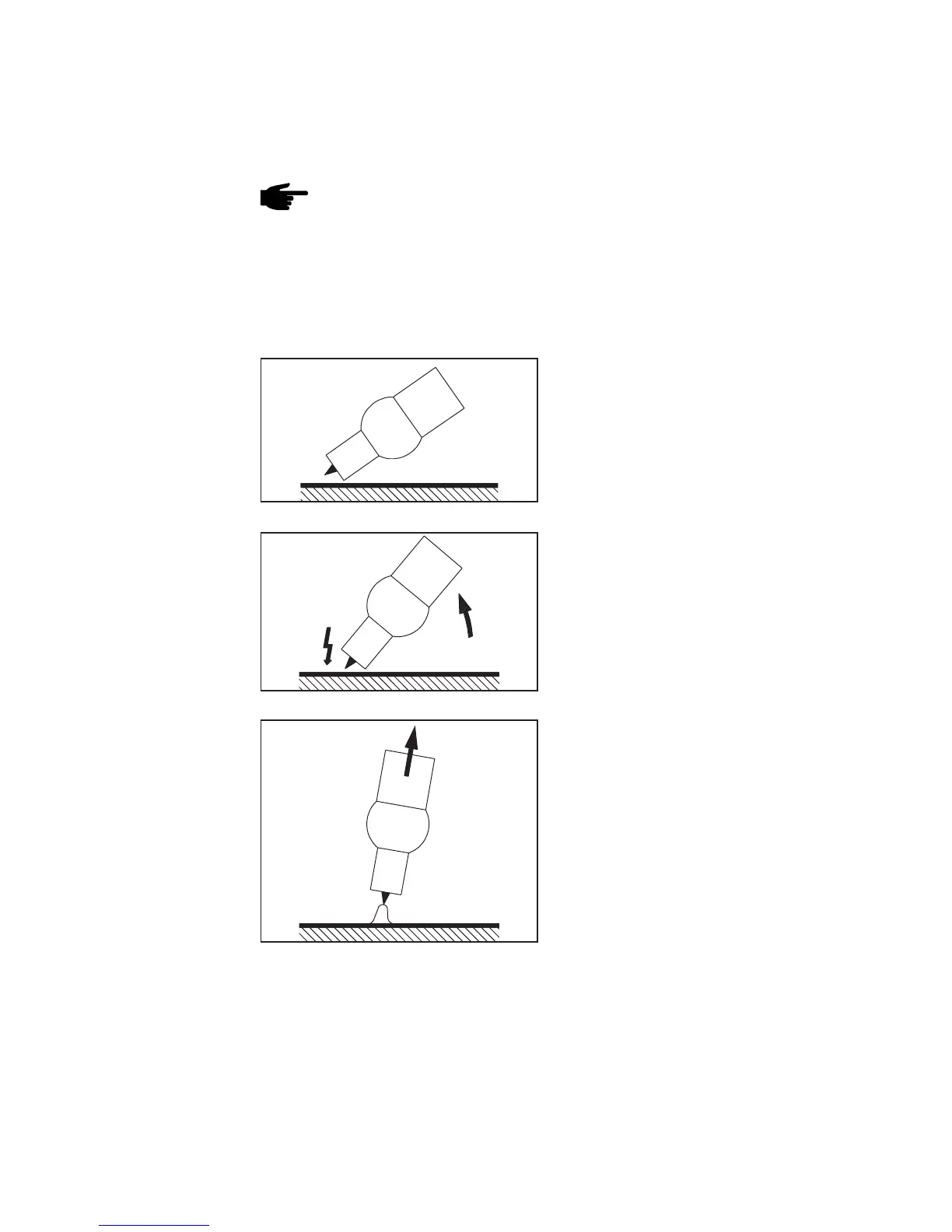

- Place the gas nozzle down on the

ignition location in such a way that

there is a gap of approx. 2 to 3 mm

(0.08 to 0.12’’) between the tungsten

electrode and the workpiece .

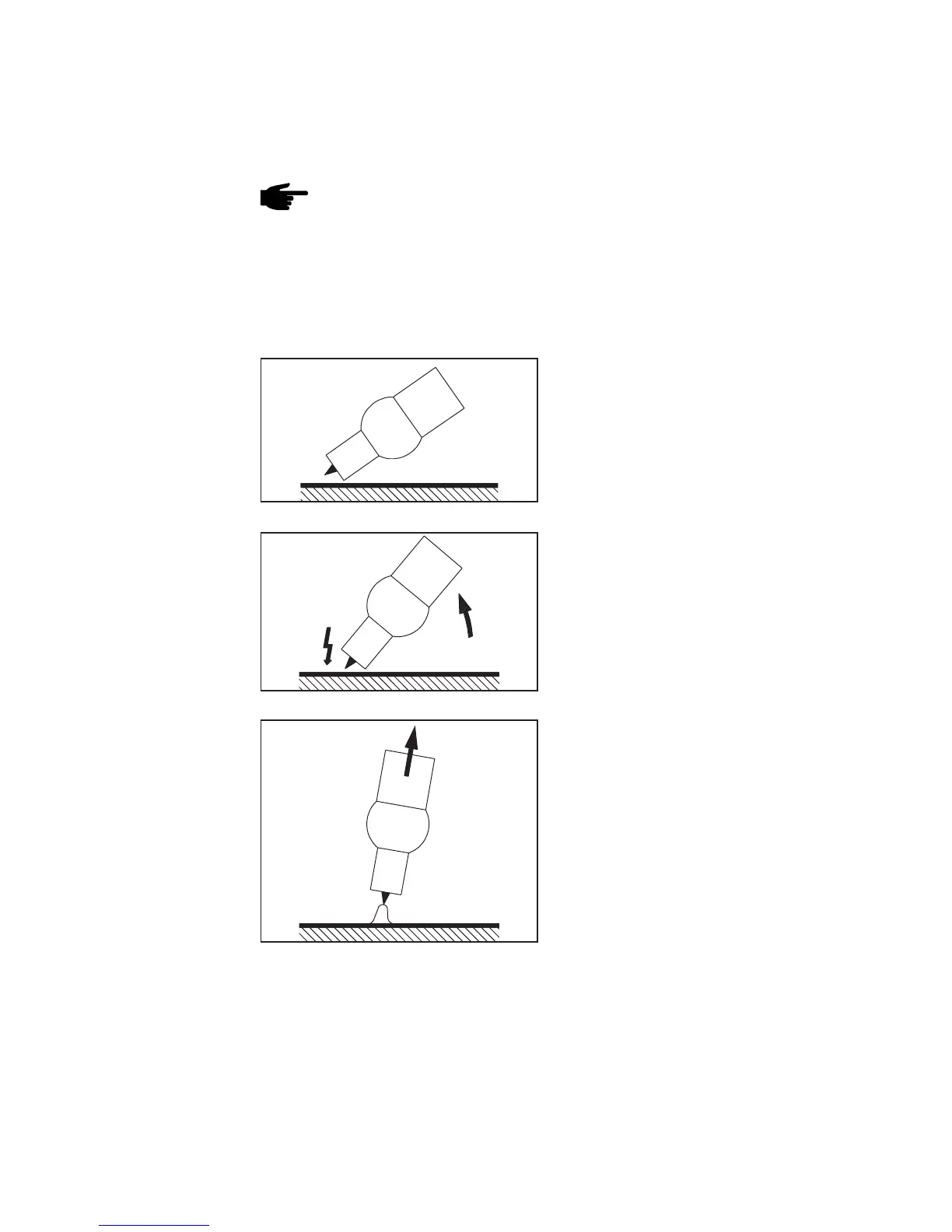

- Increase the tilt angle of the torch,

and actuate the torch trigger in the

sequence required for the operating

mode you have selected

(see the section headed “TIG opera-

ting modes”)

- The arc ignites, without the electrode

touching down on the workpiece

- Tilt the torch back into the normal

position

Fig.14 Place the gas nozzle down

Fig.15 Non-contacting HF ignition

Fig.16 Welding

HF ignition

(continued)

For details of how to adjust the set-up parameter “HFt”, please refer to the section

headed “The set-up menu: Level 2” - sub-section “TIG set-up parameters”.

Use the HFt parameter to set the time interval of the HF impulses to 0.01 s. The factory

setting (i.e. in which the power source is delivered) is: Parameter HFt = “0.01s”.

Note! If there are problems with sensitive equipment in the immediate vicinity,

increase the parameter HFt to a maximum of 0.4 s.

As compared with touchdown ignition, HF ignition eliminates the risk of contamination of

the electrode and of the workpiece.

HF ignition

Loading...

Loading...