37

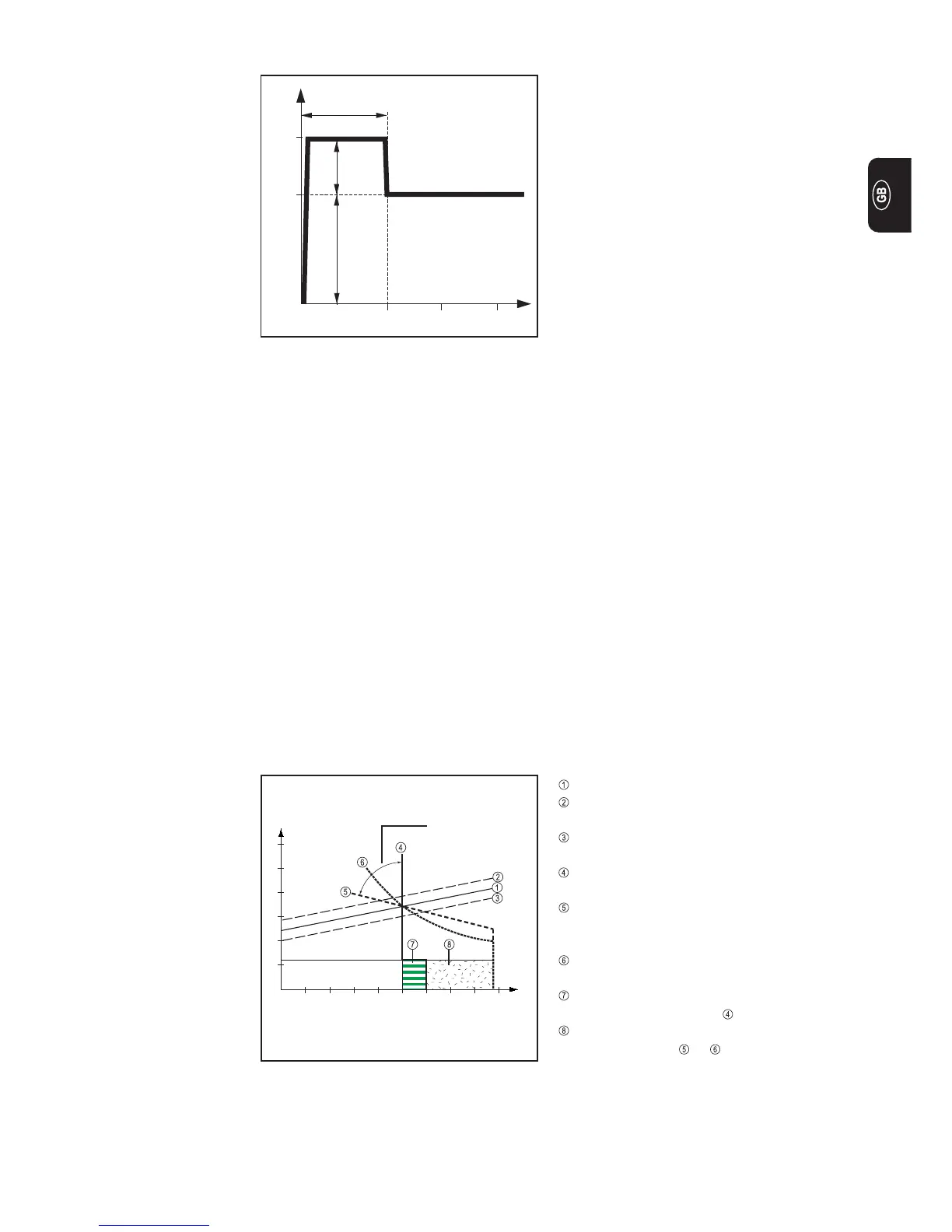

U (V)

con - 20 A / V

... Load line for rod electrode

... Load line for rod electrode where arc

length is increased

... Load line for rod electrode where arc

length is reduced

... Characteristic where “con” parameter

is selected (constant welding current)

... Characteristic where “0.1 - 20” para-

meter is selected (falling characteris-

tic with adjustable slope)

... Characteristic where “P” parameter is

selected (constant welding power)

... Example of pre-set arc force dynamic

where characteristic is selected

... Ex. of preset arc force dynamic where

characteristic or is selected

0 1005025 75 I (A)

Fig.22 Characteristics that can be selected using

the Eln function

“Eln” characteri-

stic-selection

function

Important! For details on setting the “Eln” set-up parameter, please see “The set-up

menu: Level 2” - sub-section “Rod-electrode set-up parameters”.

Dynamic (arc

force) function

In order to obtain optimum welding results, it will sometimes be necessary to set or

adjust the “Dynamic (arc-force)” function. For details on setting the “dYn” parameter,

please see “The Set-up menu: Level 1” - sub-section “Rod-electrode set-up parameters”.

Functional principle

At the instant of droplet transfer, i.e. when a short circuit occurs, there is a momentary

rise in the amperage. In order to obtain a stable arc, the welding current is temporarily

increased. If the rod electrode threatens to sink into the weld pool, this measure pre-

vents the weld-pool solidifying, as well as preventing more prolonged short-circuiting of

the arc. This largely prevents the rod-electrode from “sticking”.

Setting-range of the dYn parameter

0 ........ soft, low-spatter arc

100 .... harder, more stable arc

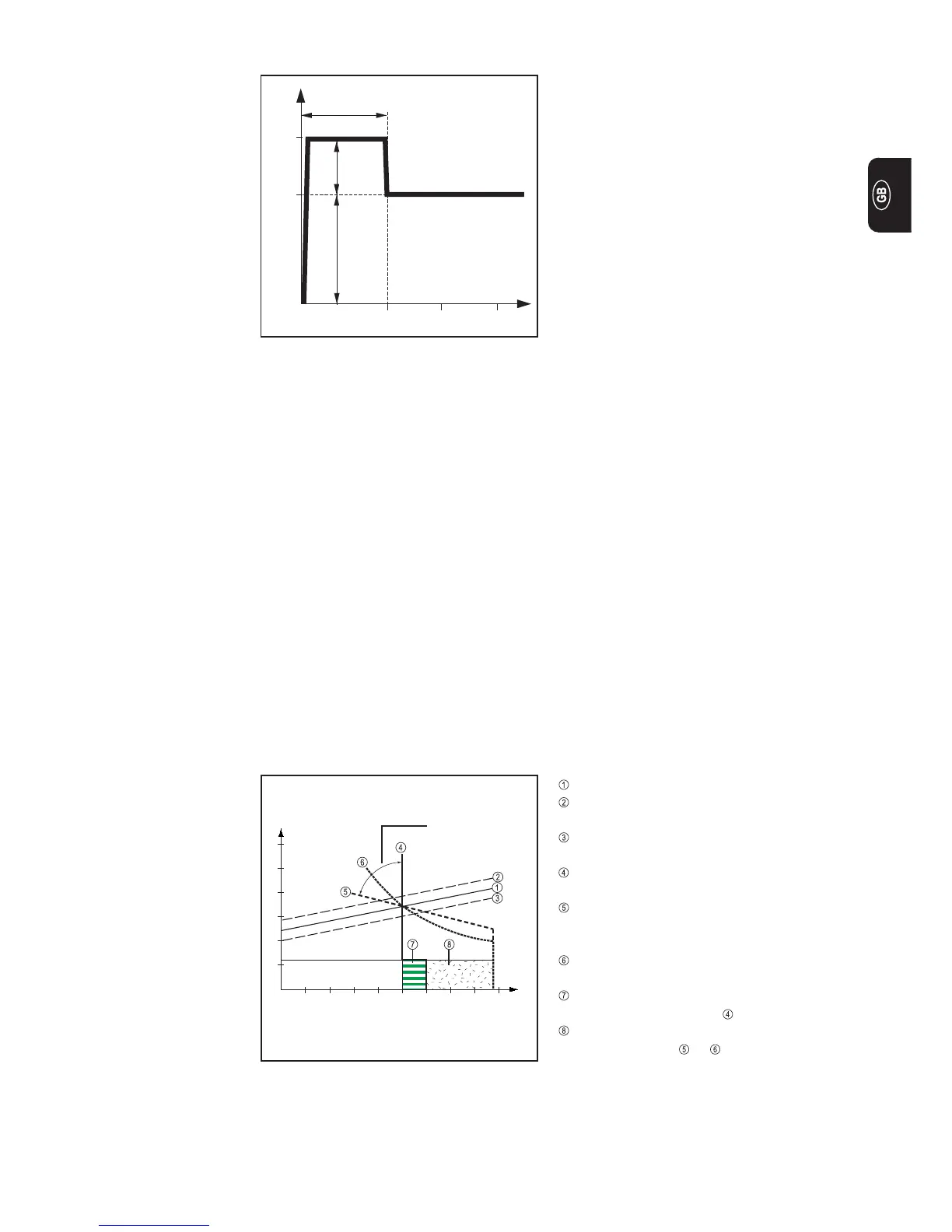

I (A)

t (s)

0,5 1 1,5

Hti

I

1

HCU

100

150

Fig.21 Example of “Hot-Start” function

Legend

Hti ...... Hot-current time, 0-2 s, factory

setting: 0.5 s

HCU .. Hot-start current, 0-100%, factory

setting: 50 %

I

1

........ Main current = Pre-set welding

current

Mode of functioning

During the pre-set hot-current time (Hti),

the welding current is increased to a

certain value. This value (HCU) is 0-100%

higher than the pre-set welding current

(I

1

).

Hot-Start func-

tion

(continued)

Loading...

Loading...