2

How to lift up the system

Strap the system safely and securely in the slings working from

the bottom, then lift up from the ground.

This welding machine has a robust handle built into the frame for

moving the equipment.

NOTE: These hoisting and transportation devices conform to Eu-

ropean standards. Do not use other hoisting and transportation

systems.

Opening the packaging

The system essentially consists of:

• CONVEX 330-400-500 basic weld unit.

• Separately:

- HS4 wire-feeder unit (supplied separately).

- MIG-MAG welding torch (optional).

-

Wire-feeder/generator interconnection cable (supplied sep-

arately).

- Coolant unit for welding torch (optional).

- Trolley to carry it around (optional).

Perform the following operations on receiving the apparatus:

•

Remove the welding generator and all accessories and compo-

nents from the packaging.

•

Check that the welding apparatus is in good condition; otherwise

immediately inform the retailer or distributor.

•

Check that all the ventilation grilles are open and that there is

nothing to obstruct the correct air flow.

Installation and connections

The installation site for the system must be carefully chosen in or-

der to ensure its satisfactory and safe use. The user is responsi-

ble for the installation and use of the system in accordance with

the producer’s instructions contained in this manual. Before install-

ing the system the user must take into consideration the potential

electromagnetic problems in the work area. In particular, we sug-

gest that you should avoid installing the system close to:

• Signalling, control and telephone cables.

• Radio and television transmitters and receivers.

• Computers and control and measurement instruments.

• Security and protection instruments.

Persons fitted with pace-makers, hearing aids and similar equip-

ment must consult their doctor before going near a machine in op-

eration. The equipment’s installation environment must comply to

the protection level of the frame.

The welding unit is characterised by class “S” use, which means

that the equipment can be used in settings in which there is a

heightened risk of electrical shock.

This system is cooled by means of the forced circulation of air, and

must therefore be placed in such a way that the air may be easily

sucked in and expelled through the apertures made in the frame.

Assemble the system in the following way:

• Assemble the trolley.

• Fixing the cooling unit to the trolley.

• Fixing of the welding machine to the trolley and the cooling unit

(electrical and plumbing connections).

• Fitting the feeder unit to the generator.

• Connect up the welder to the mains.

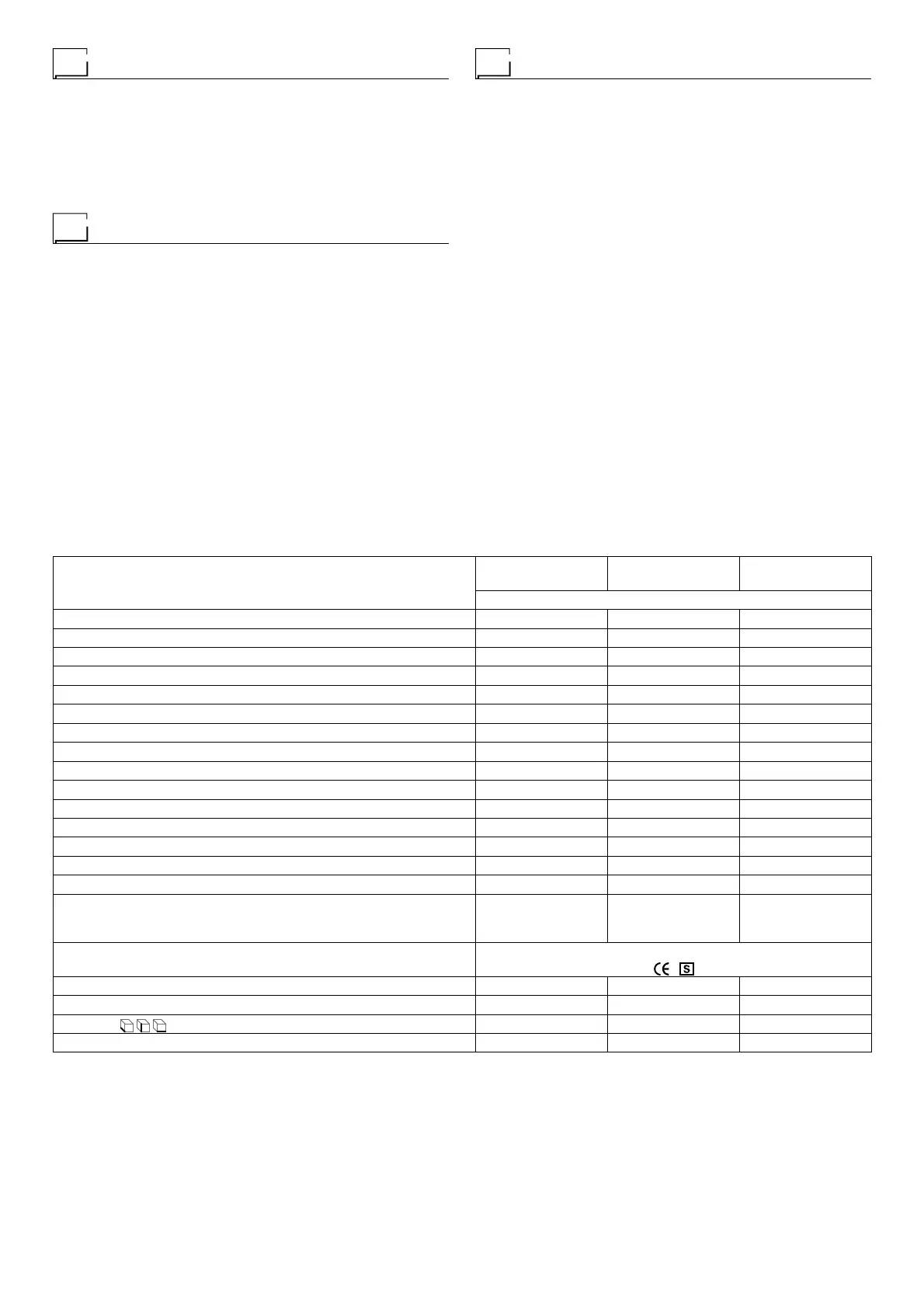

Table 1

Modell

CONVEX 330

basic

CONVEX 400

basic

CONVEX 500

basic

MIG-MAG welding

Three-phase input 50/60 Hz V 400 ± 20% 400 ± 20% 400 ± 20%

Mains supply: Z

max

Ω 0,037 0,028 0,017

Input power @ I

2

Max kVA 18,8 18,6 25,6

Delayed fuse (I

2

@ 60%) A252535

Power factor / cosφ 0,86 / 0,99 0,9 / 0,99 0,94 / 0,99

Efficiency degree η 0,82 0,88 0,89

Open circuit voltage V637070

Current range A 10-330 10÷400 10÷500

Duty cycle @ 100% (40°C) A 280 310 380

Duty cycle @ 60% (40°C) A 300 370 460

Duty cycle @ X% (40°C) A 330 (40%) 400 (50%) 500 (50%)

Wires diameter (*) mm 0,6÷1,2 (*) 0,6÷1,6 (*) 0,6÷2,0 (*)

N° rollers (*) 4 (*) 4 (*) 4 (*)

Power output of feeder motor (*) W 100 (*) 100 (*) 100 (*)

Rated wire feeding speed (*) m/min 0,5÷25 (*) 0,5÷25 (*) 0,5÷25 (*)

Spool (*)

Diameter

Weight

mm

kg

Ø300 (*)

15 (*)

Ø300 (*)

15 (*)

Ø300 (*)

15 (*)

Standards

IEC 60974-1 / IEC 60974-5 (*) / IEC 60974-10

Protection class IP 23 S IP 23 S IP 23 S

Insulation class HHH

Dimensions

mm 660 - 515 - 290 660 - 515 - 290 660 - 515 - 290

Weight kg 35 39 43

(*) On the HS4 feeder, fitted separately.

WARNING: This equipment complies with EN//IEC 61000-3-12 provided that the maximum permissible system impedance Z

max

is less than or

equal to 0,037 CONVEX 330 basic - 0,028 CONVEX 400 basic - 0,017 CONVEX 500 basic at the interface point between the user’s supply and

the public system. It is the responsibility of the installer or user of the equipment to ensure, by consultation with the distribution network opera-

tor if necessary, that the equipment is connected only to a supply with maximum permissible system impedance Z

max

less than or equal to 0,037

CONVEX 330 basic - 0,028 CONVEX 400 basic - 0,017 CONVEX 500 basic.

This system, tested according to EN/IEC 61000-3-3, meets the requirements of EN/IEC 61000-3-11.

Loading...

Loading...