10

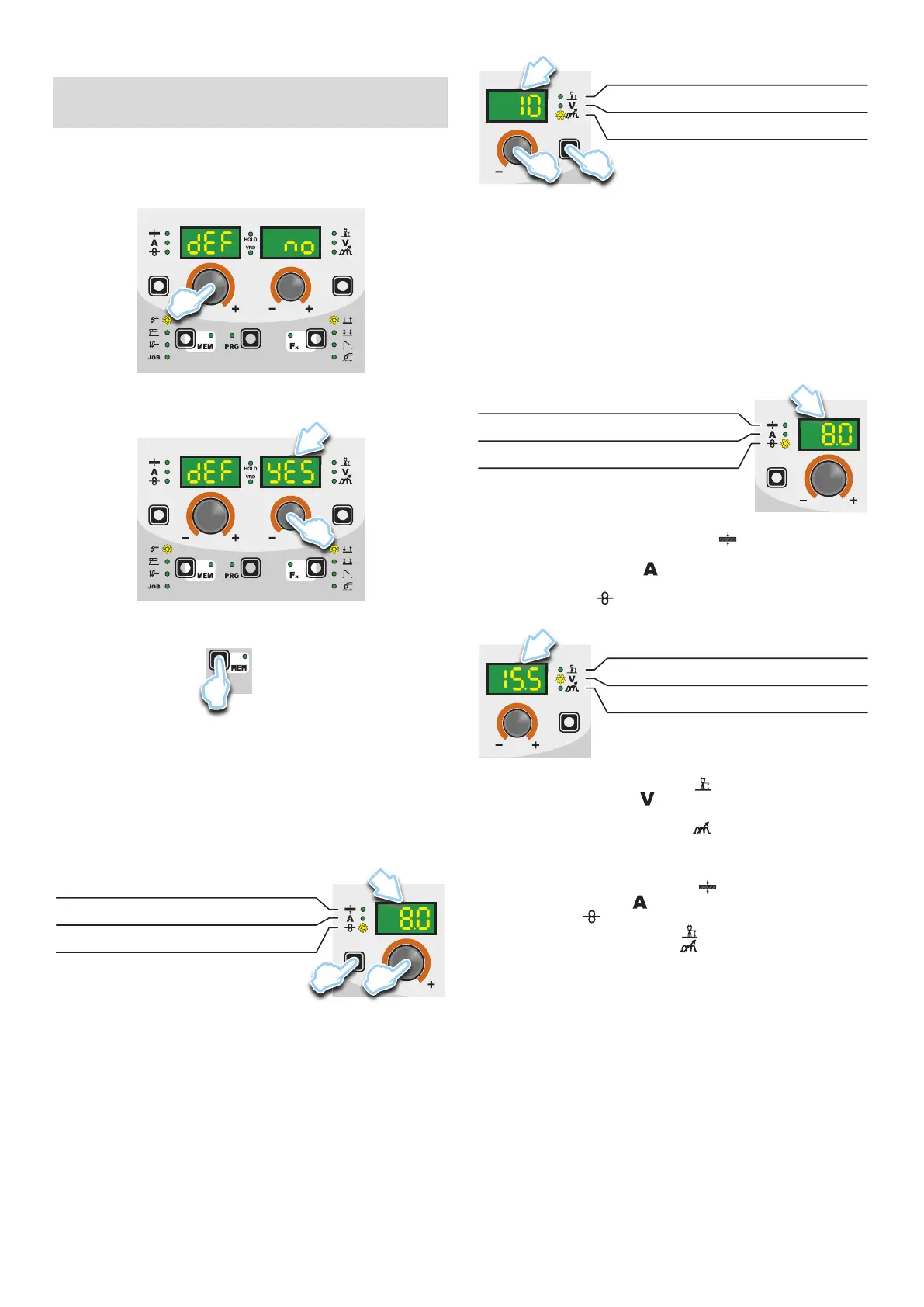

■ PROGRAM DEFAULT (dEF)

WARNING: If carried out, this operation resets the program

in use to the factory default settings.

To carry out the reset of the settings / parameters, proceed in the

following manner:

•

Rotate the ENCODER - A (E1) knob until both the displays read

dEF no (see figure).

E1

•

Rotate the ENCODER - V knob (E2) until the PARAMETERS

DISPLAY - V screen (D2) reads YES.

D2

E2

•

Hold the SAVE “MEM” key (T2) down for at least 2 consecu-

tive seconds.

T2

T ≥ 2 s

•

The program in use has now been completed successfully. To

confirmation the above, the control panel of the welder performs

a short operation of MACHINE CHECK (all of the LED stay lit

simultaneously so as to verify their actual operation), the gen-

erator itself starts, having memorised the new settings and is

again ready to weld.

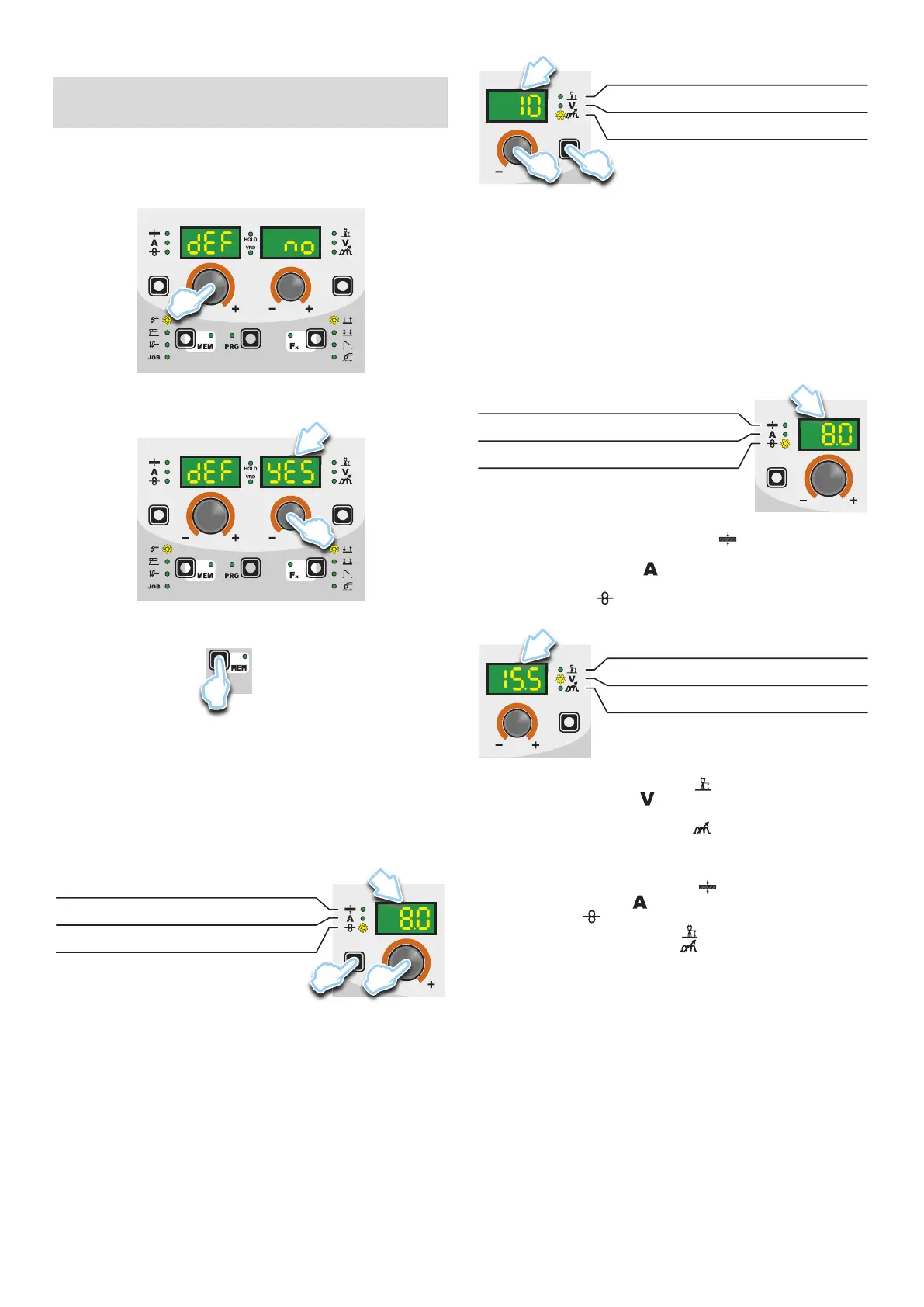

5 - PRE-SETTING

Before welding it is possible to set the following parameters:

D1

T1

E1

THICKNESS OF WELDED ITEM

WELDING CURRENT

WIRE SPEED

Example: WIRE SPEED

Press the PARAMETER SELECTION - A key (T1) until the LED

that corresponds to the WIRE SPEED switches on. Turn the EN-

CODER - A knob (E1) to change the value shown on the PARAM-

ETER DISPLAY - A screen (D1).

D2

T4

E2

ELECTRONIC INDUCTANCE

WELDING VOLTAGE (*)

ARC LENGTH ADJUSTMENT

(*) The parameter is pre-set by means of synergy and can be changed

by varying the ARC LENGTH ADJUSTMENT parameter.

Example: ELECTRONIC INDUCTANCE

Press the PARAMETER SELECTION - V key (T4) until the LED

that corresponds to the ELECTRONIC INDUCTANCE switches

on. Turn the ENCODER - V knob (E2) to change the value shown

on the PARAMETER DISPLAY - V screen (D2).

6 - WELDING

During the welding the display shows:

• PARAMETER DISPLAY screen - A (D1)

D1

THICKNESS OF WELDED ITEM

WELDING CURRENT

WIRE SPEED

-

THICKNESS OF WELDED ITEM ( ): the value previous-

ly set.

-

WELDING CURRENT ( ): the measured value of the current

of what is being welded.

- WIRE SPEED (

): the value previously set.

• PARAMETER DISPLAY screen - V (D2)

D2

ELECTRONIC INDUCTANCE

WELDING VOLTAGE

ARC LENGTH ADJUSTMENT

- ARC LENGTH ADJUSTMENT ( ): the value previously set.

-

WELDING VOLTAGE ( ): the measured value of the voltage

of what is being welded.

- ELECTRONIC INDUCTANCE (

): the value previously set.

During the welding the operator can change the following param-

eters:

• THICKNESS OF WELDED ITEM (

).

• WELDING CURRENT (

).

• WIRE SPEED (

).

• ARC LENGTH ADJUSTMENT (

).

• ELECTRONIC INDUCTANCE (

).

• SPECIAL FUNCTIONS “Fx”.

WARNING: Remember that this process of welding is synergic

and for this reason the alteration of an individual parameter syn-

ergically also influences other parameters according to the pre-

defined settings that are not modifiable!

Loading...

Loading...