12

3 - SPECIAL FUNCTIONS “Fx” SELECTION

The SPECIAL FUNCTIONS “Fx” that are only available in the MIG-

MAG manual welding process are shown below. For all the other

explanations regarding this menu make reference to the relative

paragraph.

•

PRE GAS (PrG) - Provides an additional quantity of gas for a

defined time, before welding starts.

•

STARTING SPEED (StS) - Regulates the speed at which the

wire approaches the workpiece. The value indicated is a percent-

age variation in relation to the factory setting value.

• HOT START (HoT) - Regulates the current intensity for igniting

the welding arc. The value indicated is a percentage variation

in relation to the factory setting value.

•

CRATER START SPEED (F08) - Sets the initial speed of the

welding wire for the crater.

•

CRATER START VOLTAGE (F09) - Sets the initial welding volt-

age for the crater.

•

CRATER START TIME (F10) - This function defines the time

in which the current remains at the value of CRATER START

SPEED or CRATER START VOLTAGE.

•

CRATER START SLOPE (F11) - Time taken to go from the CRA-

TER START SPEED or CRATER START VOLTAGE level to the

welding speed or voltage level.

•

CRATERENDSLOPE(F12)- Time required to go from the

welding speed or voltage level to the CRATER END SPEED or

CRATER END VOLTAGE level.

• CRATER END SPEED (F13) - Sets the final speed of the weld-

ing wire for the crater.

•

CRATER END VOLTAGE (F14) - Sets the final welding volt-

age for the crater

•

CRATER END TIME (F15) - This function defines the time in

which the current remains at the value of CRATER END SPEED

or CRATER END VOLTAGE.

• SPOT WELD TIME (F07) - The time during which spot welding

takes place after the arc is ignited, after which the arc is extin-

guished automatically.

•

STITCH WELD TIME (F05) - Time in which the welding in tracts

is performed after the ignition of the arch, after which the arch

switches off automatically.

•

STITCH WELD PAUSE (F06) - Time of pause between one

welding in tracts and another.

•

BURN BACK (bUb) - Regulates the length of the wire after weld-

ing. The value indicated is a percentage variation in relation to

the factory setting value. Higher numbers correspond to more

burning of the wire.

• POST GAS (PoG) - Provides an additional quantity of gas for a

defined time, after welding ends.

■ PROGRAM DEFAULT (dEF)

WARNING: If carried out, this operation resets the program

in use to the factory default settings.

To carry out the reset of the settings / parameters, proceed in the

following manner:

•

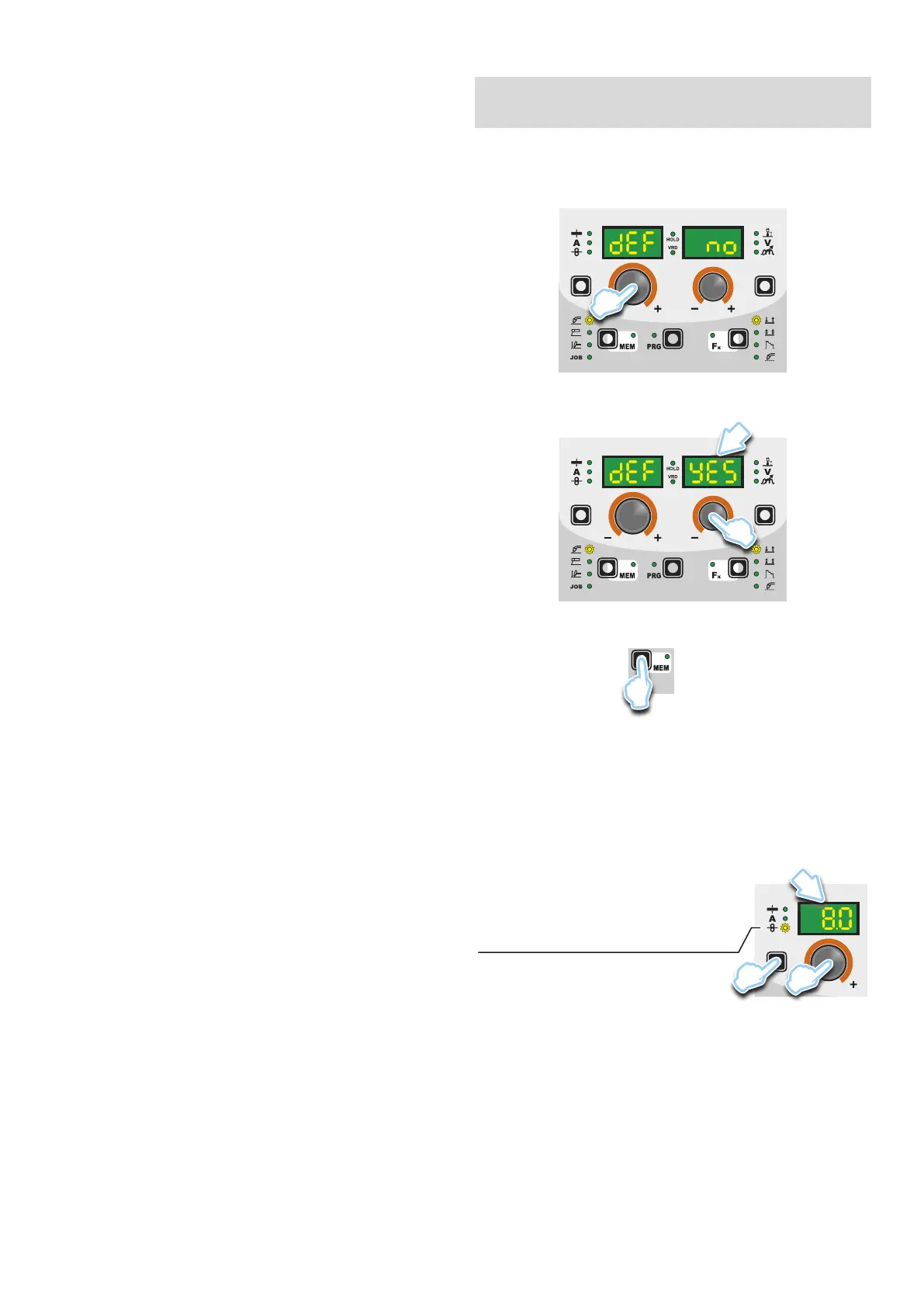

Rotate the ENCODER - A (E1) knob until both the displays read

dEF no (see figure).

E1

•

Rotate the ENCODER - V knob (E2) until the PARAMETERS

DISPLAY - V screen (D2) reads YES.

D2

E2

•

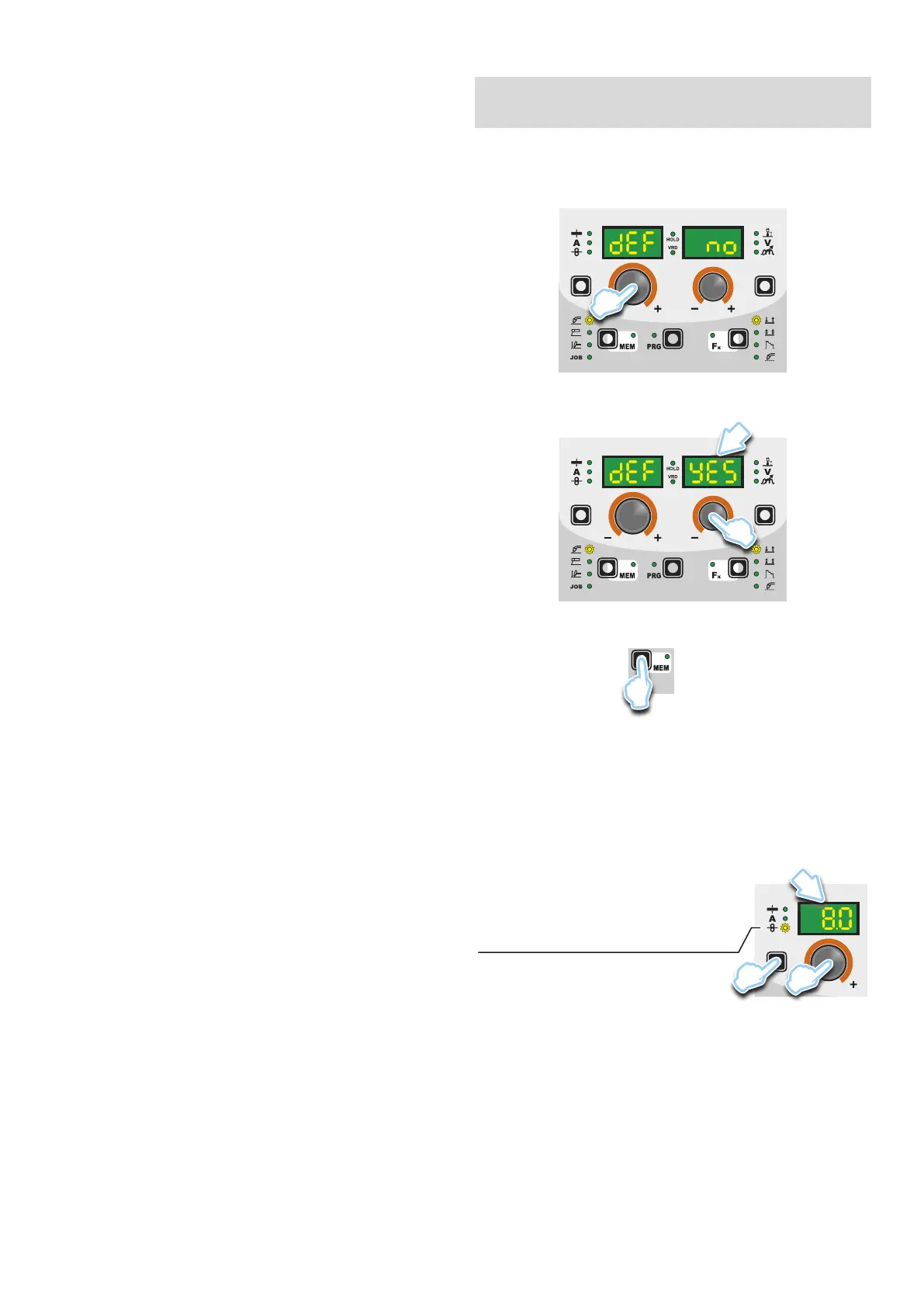

Hold the SAVE “MEM” key (T2) down for at least 2 consecu-

tive seconds.

T2

T ≥ 2 s

•

The program in use has now been completed successfully. To

confirmation the above, the control panel of the welder performs

a short operation of MACHINE CHECK (all of the LED stay lit

simultaneously so as to verify their actual operation), the gen-

erator itself starts, having memorised the new settings and is

again ready to weld.

4 - PRE-SETTING

Before welding it is possible to set the following parameters:

D1

T1

E1

WIRE SPEED

Example: WIRE SPEED

Press the PARAMETER SELECTION - A key (T1) until the LED

that corresponds to the WIRE SPEED switches on. Turn the EN-

CODER - A knob (E1) to change the value shown on the PARAM-

ETER DISPLAY - A screen (D1).

Loading...

Loading...