9

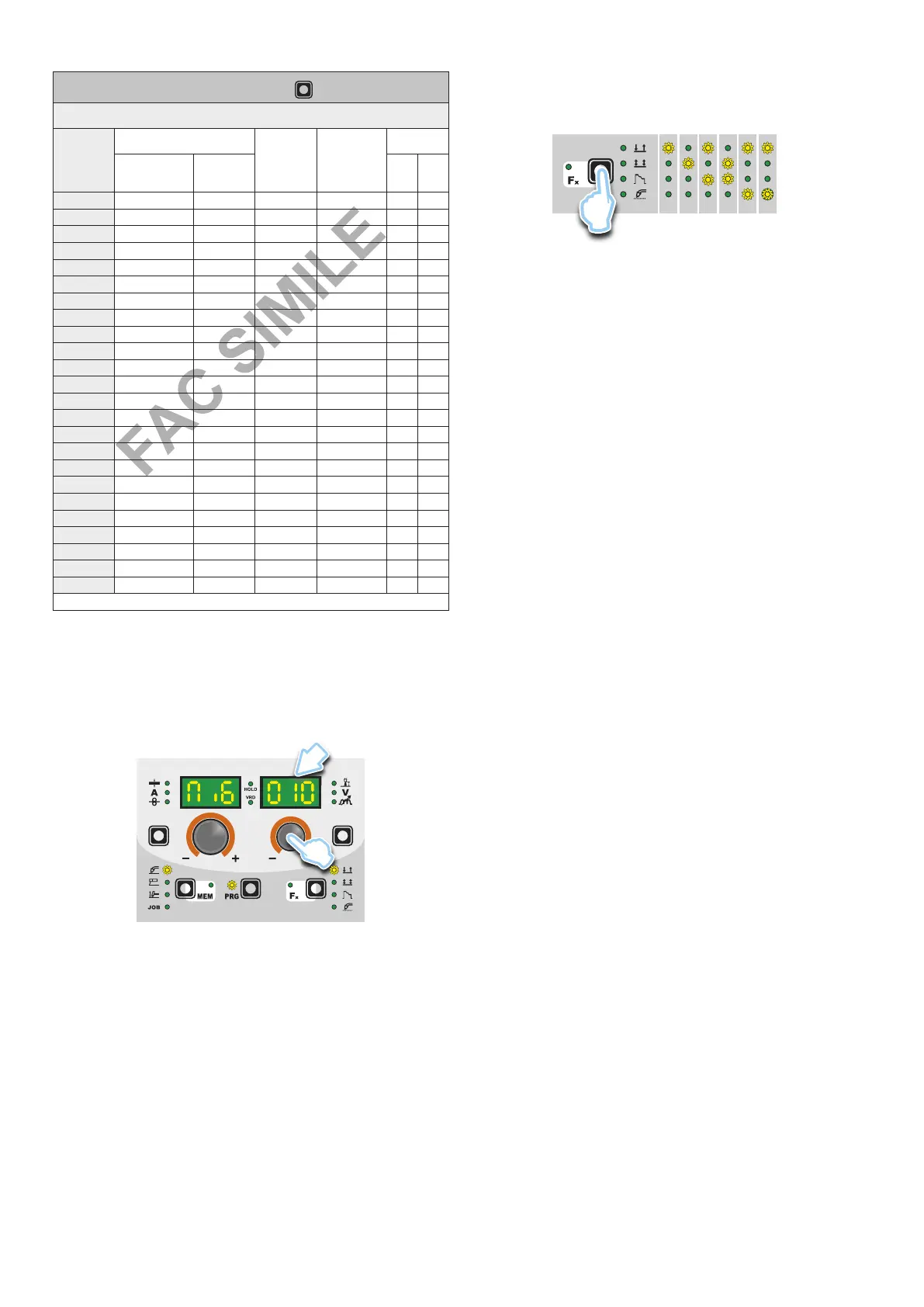

2-SELECTIONOFWELDINGPROGRAMME

PROGRAM TABLE PRG

MIG-MAG-PULSE PROCESS

PROGRAM

NUMBER

MATERIAL

WIRE Ø

(mm)

GAS

DISPLAYS

TYPE CLASS MiG

PLS

dPL

000 Fe G3 Si-1 0.6 CO

2

●

001 Fe G3 Si-1 0.8 CO

2

●

002 Fe G3 Si-1 1.0 CO

2

●

010 Fe G3 Si-1 0.6 Ar/16-20%CO

2

●

011 Fe G3 Si-1 0.8 Ar/16-20%CO

2

● ●

012 Fe G3 Si-1 1.0 Ar/16-20%CO

2

● ●

015 Fe G3 Si-1 0,9 Ar/16-20%CO

2

● ●

051 Fe G3 Si-1 0.8 Ar/21-25%CO

2

●

055 Fe G3 Si-1 0.9 Ar/21-25%CO

2

●

195 Fe-rutil flux-cored E71T-GS 0.9 - ●

231 CrNi 308 G 19 9 LSI 0.8 Ar/2-3%CO

2

● ●

232 CrNi 308 G 19 9 LSI 1.0 Ar/2-3%CO

2

● ●

402 Al 99.9 S Al 1050 1.0 Ar ● ●

403 Al 99.9 S Al 1050 1.2 Ar ● ●

412 Al Mg 5 S Al 5356 1.0 Ar ● ●

413 Al Mg 5 S Al 5356 1.2 Ar ● ●

422 Al Si 5 S Al 4043A 1.0 Ar ● ●

423 Al Si 5 S Al 4043A 1.2 Ar ● ●

472 Al Si12 S Al 4047A 1.0 Ar ● ●

511 Cu Si 3 S CuSi3 0.8 Ar ● ●

512 Cu Si 3 S CuSi3 1.0 Ar ● ●

515 Cu Si 3 S CuSi3 0.9 Ar ● ●

911 Fe BD140 0.8 Ar/16-20%CO

2

● ●

951 Fe BD140 0.8 Ar/21-25%CO

2

●

PLS / dPL= Pulse version only

WARNING: This table is merely an example, the welding programs

can be updated and extended. See the table on the welding ma-

chine for the correct list of the programs available.

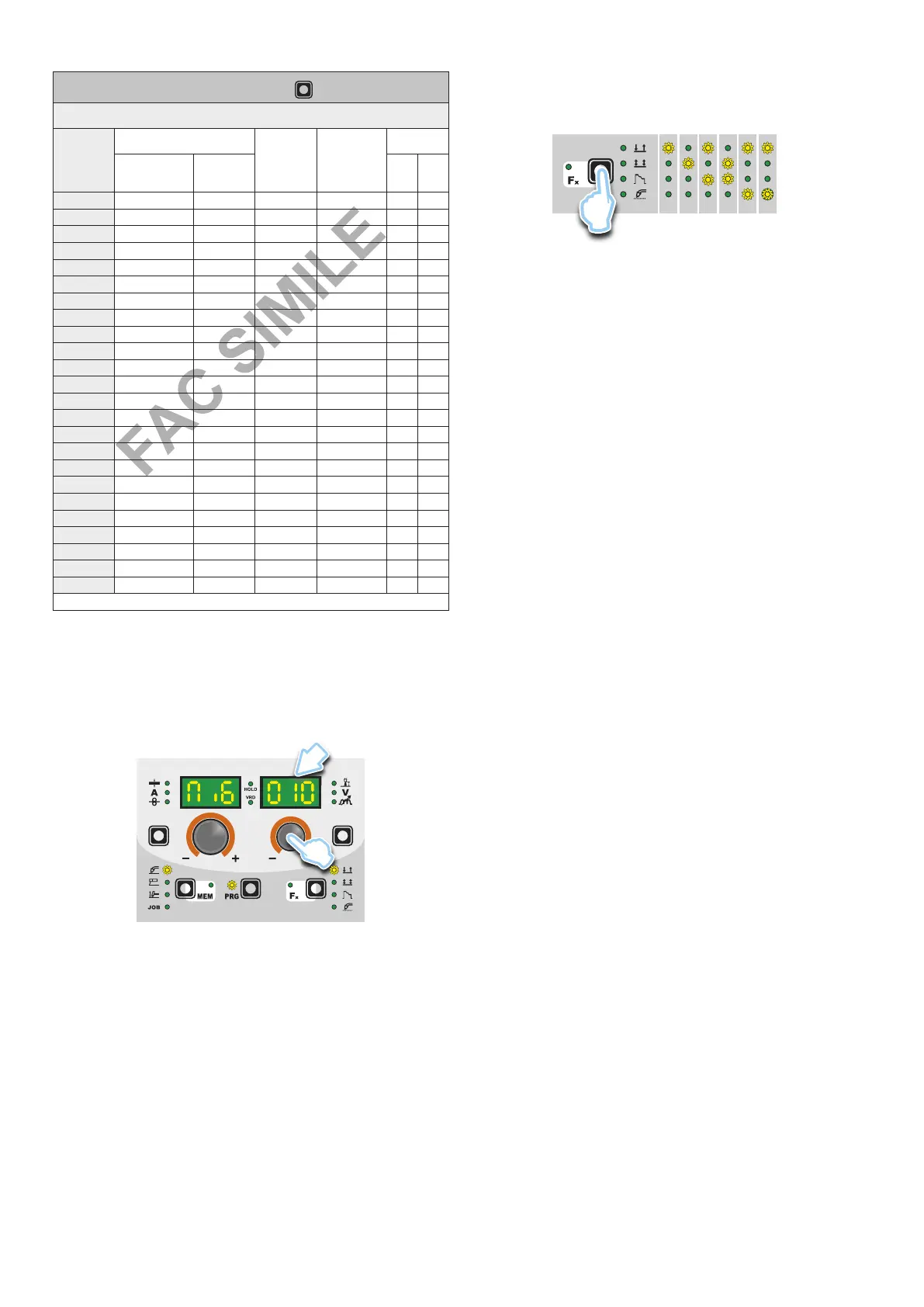

Select the welding PROGRAMME rotating ENCODER knob - V

(E2) until obtaining on the PARAMETER DISPLAY screen - V (D2)

the desired number.

D2

E2

3 - WELDING MODE SELECTION

Select the MODE of welding, pressing and releasing, even various

times if necessary, the WELDING MODE SELECTION key (T3)

until the corresponding LED lights up.

1 2 3 4 5 6

T3

1. TWO STROKE (2T)

2. FOUR STROKE (4T)

3. CRATER 2T

4. CRATER 4T

5. SPOT WELDING 2T

6. STITCH WELDING 2T

4 - SPECIAL FUNCTIONS “Fx” SELECTION

The SPECIAL FUNCTIONS “Fx” that are only available in the syn-

ergic MIG-MAG and pulsed / double pulsed MIG welding process

are shown below. For all the other explanations regarding this

menu make reference to the relative paragraph.

•

PRE GAS (PrG) - Provides an additional quantity of gas for a

defined time, before welding starts.

•

STARTING SPEED (StS) - Regulates the speed at which the

wire approaches the workpiece. The value indicated is a percent-

age variation in relation to the factory setting value.

• HOT START (Hot) - Regulates the current intensity for igniting

the welding arc. The value indicated is a percentage variation

in relation to the factory setting value.

•

CRATER START CURRENT (F08) - Sets the initial starting cur-

rent of the crater.

•

CRATER START TIME (F10) - This function defines the time

in which the current remains at the value of CRATER START

CURRENT.

•

CRATER START SLOPE (F11) - The time lapse for passing

from the CRATER START CURRENT level to the welding cur-

rent level.

•

CRATERENDSLOPE(F12)- Time required to go from the

welding current level to the “CRATER END CURRENT” level.

•

CRATER END CURRENT (F13) - Sets the final welding cur-

rent of the crater.

•

CRATER END TIME (F15) - This function defines the time in

which the current remains at the value of CRATER END CUR-

RENT.

• SPOT WELD TIME (F07) - The time during which spot welding

takes place after the arc is ignited, after which the arc is extin-

guished automatically.

•

STITCH WELD TIME (F05) - Time in which the welding in tracts

is performed after the ignition of the arch, after which the arch

switches off automatically.

•

STITCH WELD PAUSE (F06) - Time of pause between one

welding in tracts and another.

•

BURN BACK (bUb) - Regulates the length of the wire after weld-

ing. The value indicated is a percentage variation in relation to

the factory setting value. Higher numbers correspond to more

burning of the wire.

• POST GAS (PoG) - Provides an additional quantity of gas for a

defined time, after welding ends.

•

DUALPULSEDELTACURRENT(F23)- This function deter-

mines the positive or negative percentage variation in the peak

current, compared to the welding current set.

• DUALPULSEBALANCE(F25)- This function determines the

positive or negative percentage variation in the duration of the

peak current, compared to that of the welding current.

•

DUALPULSEFREQUENCY(F26)- This function determines

the variation in frequency (Hz) for double pulsed mode.

Loading...

Loading...