18

JOB

1 - CREATING AND SAVING A JOB

This operation makes it possible to create and save welding set-

tings (points) that can be called up by the operator at any time.

The control panel provides the possibility of saving a total of 99

JOBS spread over all the welding processes. There are not lim-

its to the quantity or position of the points that can be saved for

each process!

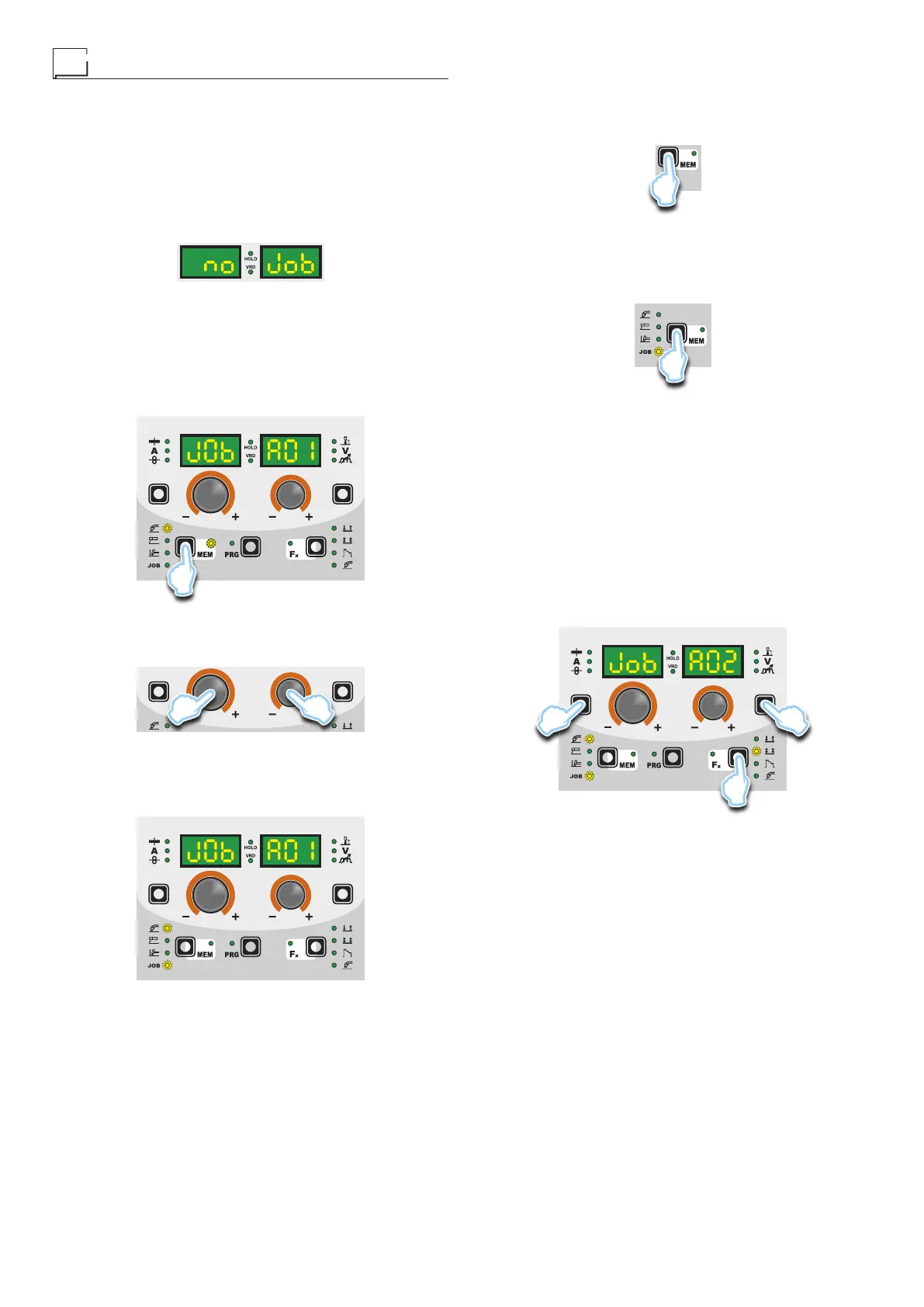

When it leaves the factory the welding machine does not have

any JOBS saved in it and so the operator will find the control pan-

el in this condition:

Having defined the parameters the operator needs to do their work

correctly, they can be saved by creating an AUTOMATIC WELD-

ING POINT (JOB), proceeding as follows:

1) Hold the SAVE “MEM” key (T2) down for at least 2 consec-

utive seconds until both displays show the flashing wording

that represent the first AUTOMATIC WELDING POINT (JOB)

free and/or available to the operator that can be used for sav-

ing the data (e.g.: A01).

T2

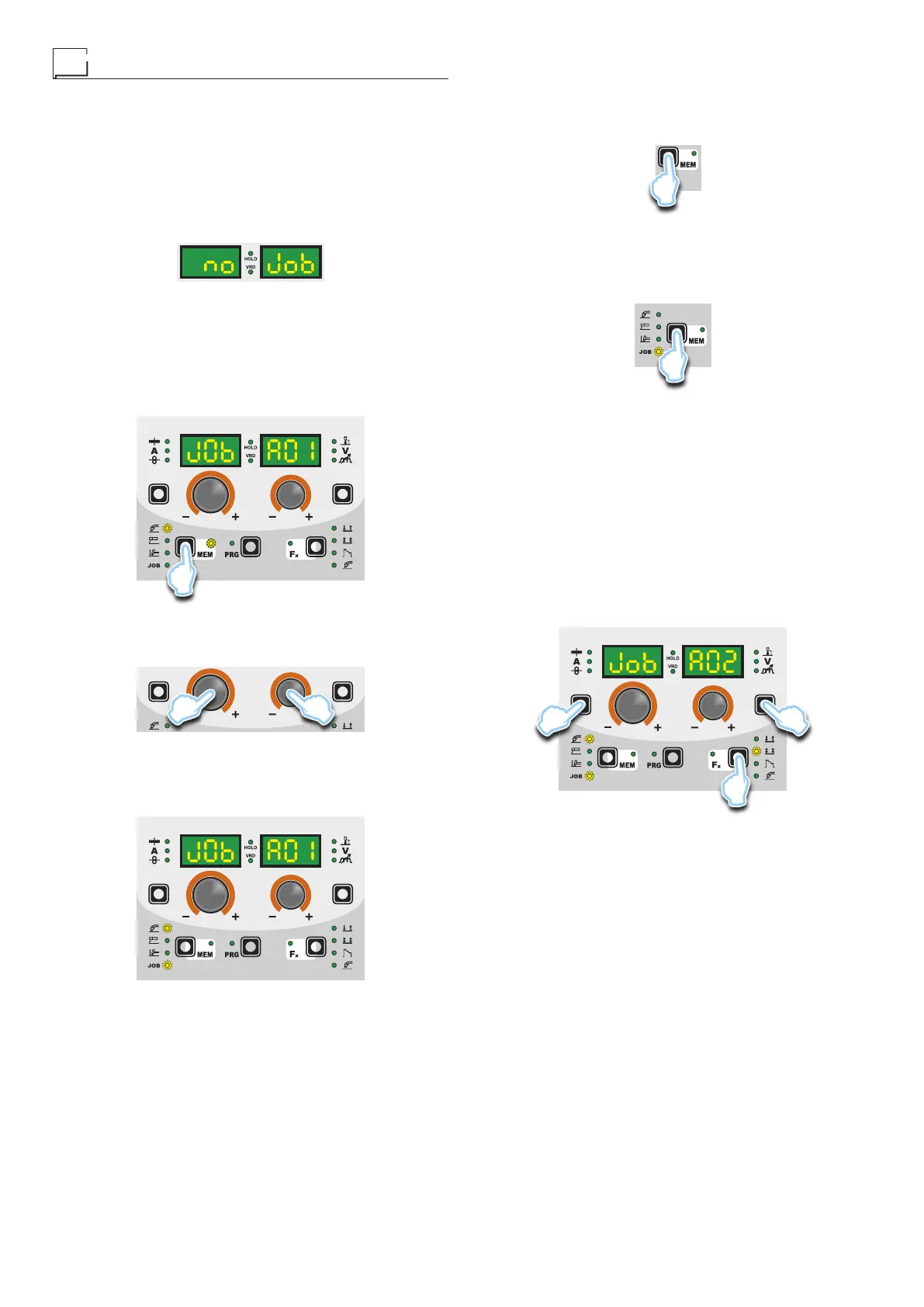

To be able to choose another automatic welding point (JOB)

that is free for saving the data, simply turn one of the two EN-

CODER (E1-E2) knobs until you reach the required point.

E2E1

WARNING: If all the automatic welding points (JOBS) are occu-

pied, the check automatically goes to the first automatic welding

point (JOB A01) as shown in the figure below).

2) Hold down the SAVE “MEM” (T2) Key down for at least 2 con-

secutive seconds to save JOB and automatically load the set-

tings / parameters (including special functions) for the JOB just

saved.

3) To exit the JOB, press and release the WELDING PROCESS

SELECTION key (T2).

T2

2-JOBSELECTION

Select the JOB, pressing and releasing, even various times if nec-

essary, the WELDING PROCESS SELECTION key (T2) until the

corresponding LED lights up.

T2

3 - PRE-SETTING / VIEWING MEMORISED JOB DATA

Since the parameters are memorised, within each JOB, viewa-

ble but not modifiable, the pre-setting phase does not exist, but

the operator can see and verify the settings, previously saved

and memorised, pressing and releasing the PARAMETER SE-

LECTION key - A (T1) or in alternative the PARAMETER SELEC-

TION key - V (T4).

The SPECIAL FUNCTIONS “Fx” Key (T3) contained within each

individual JOB can be viewed (but not modified) by simply keep-

ing the SPECIAL FUNCTIONS “Fx” key (T3) pressed for a dura-

tion of about 2 seconds.

The display of the parameters (special functions included) lasts

only a few seconds, then the panel shows, in an automatic way,

the previous working condition.

T4T1

T3

4 - WELDING

During the welding the display shows the values, if possible meas-

ured, of the active parameters, based on the type of welding pro-

cess, memorised within the selected JOB.

As already indicated, the parameters can be viewed by pressing

and releasing the PARAMETER SELECTION key - A (T1) or in al-

ternative the PARAMETER SELECTION key - V (T4), while the

SPECIAL FUNCTIONS “Fx” key (T3) contained within each indi-

vidual JOB can be viewed (but not modified) by simply keeping

the SPECIAL FUNCTIONS “Fx” key (T3) pressed for a duration

of about 3 seconds.

Loading...

Loading...