15

•

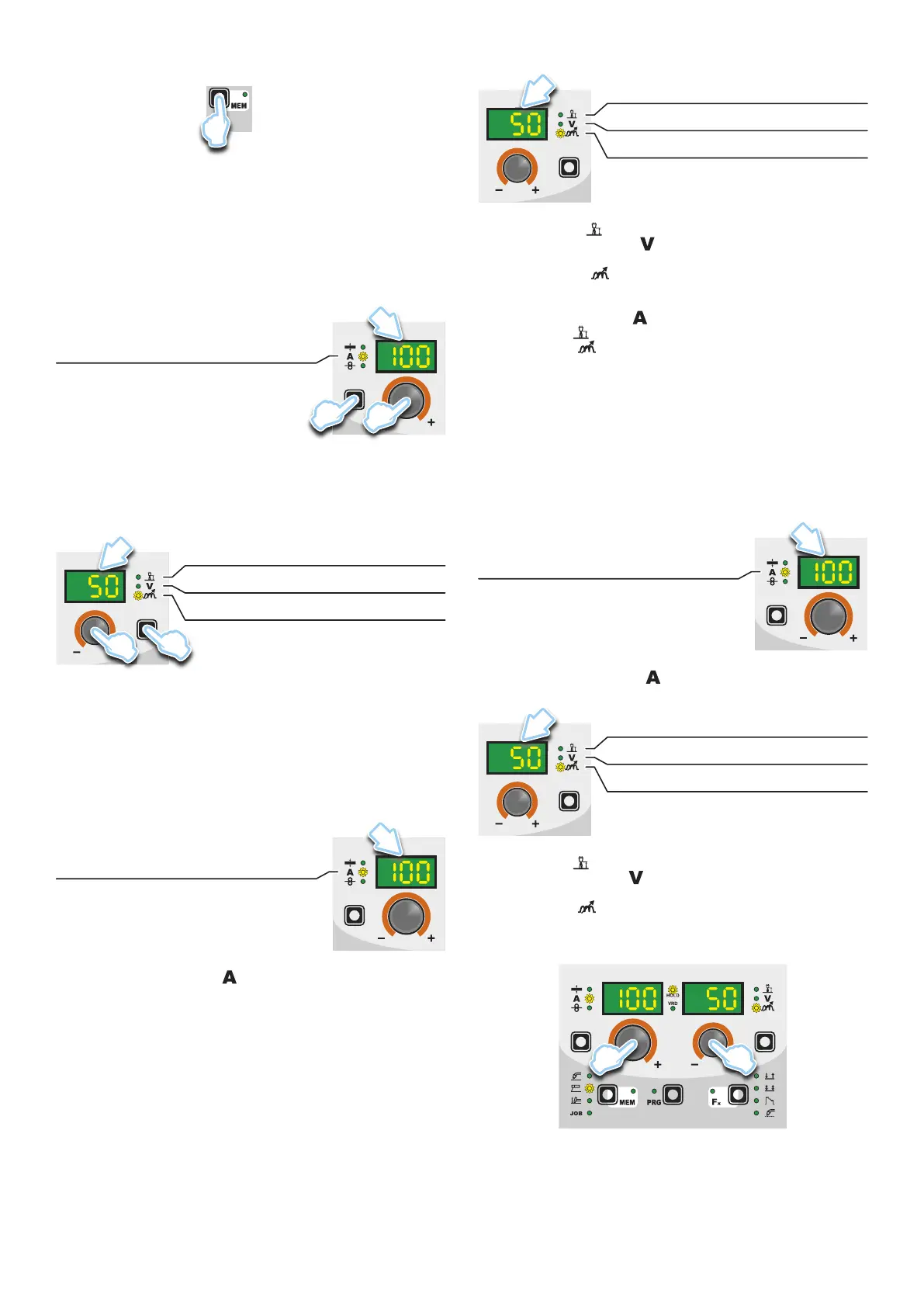

Hold the SAVE “MEM” key (T2) down for at least 2 consecu-

tive seconds.

T2

T ≥ 2 s

•

The program in use has now been completed successfully. To

confirmation the above, the control panel of the welder performs

a short operation of MACHINE CHECK (all of the LED stay lit

simultaneously so as to verify their actual operation), the gen-

erator itself starts, having memorised the new settings and is

again ready to weld.

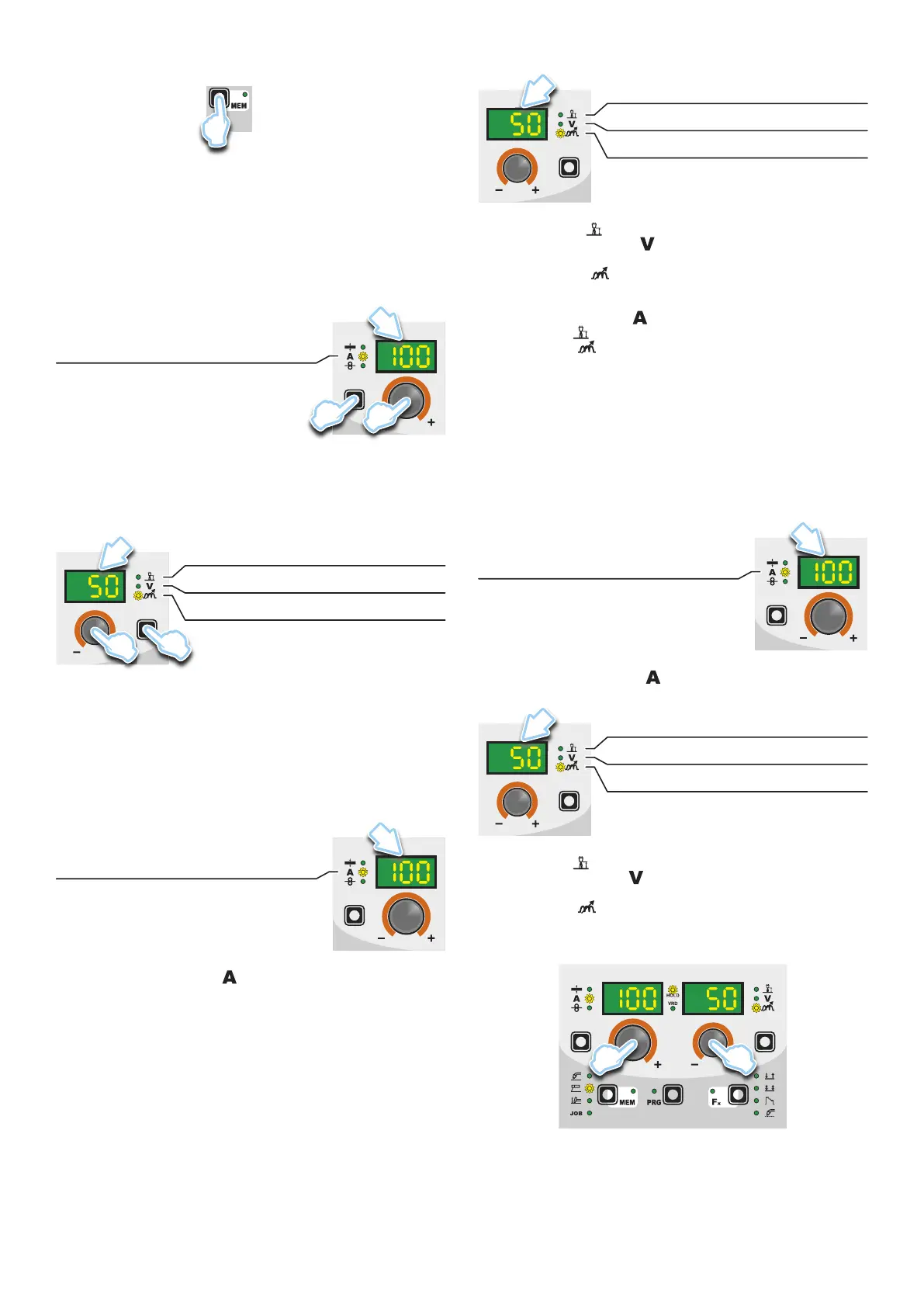

4 - PRE-SETTING

Before welding it is possible to set the following parameters:

D1

T1

E1

WELDING CURRENT

Example: WELDING CURRENT

Press the PARAMETER SELECTION - A key (T1) until the LED

that corresponds to the WELDING CURRENT switches on. Turn

the ENCODER - A knob (E1) to change the value shown on the

PARAMETER DISPLAY - A screen (D1).

D2

T4

E2

ARC FORCE

WELDING VOLTAGE

HOT START

Example: ARC FORCE

Press the PARAMETER SELECTION - V key (T4) until the LED

that corresponds to the ARC FORCE switches on. Turn the EN-

CODER - V knob (E2) to change the value shown on the PARAM-

ETER DISPLAY - V screen (D2).

5 - WELDING

During the welding the display shows:

• PARAMETER DISPLAY screen - A (D1)

D1

WELDING CURRENT

-

WELDING CURRENT ( ):the measured value of the current

of what is being welded.

• PARAMETER DISPLAY screen - V (D2)

D2

ARC FORCE

WELDING VOLTAGE

HOT START

- HOT START ( ): the value previously set.

-

WELDING VOLTAGE ( ): the measured value of the voltage

of what is being welded.

- ARC FORCE (

): the value previously set.

During the welding the operator can change the following param-

eters:

• WELDING CURRENT (

).

• HOT START (

).

• ARC FORCE (

).

• SPECIAL FUNCTIONS “Fx” - FIRST LEVEL MENU.

6 - HOLD

This function automatically starts itself at the conclusion of eve-

ry welding operation welding and it is indicated to the operator by

means of a flashing light of the HOLD FUNCTION LED for a spe-

cific amount of time. Once the welding has been terminated, for

about 15 seconds, both the DISPLAYS should show the same val-

ues of the parameters during the welding.

In this phase the displays show:

• PARAMETER DISPLAY screen - A (D1)

D1

WELDING CURRENT

- WELDING CURRENT ( ): the last current value measured.

• PARAMETER DISPLAY screen - V (D2)

D2

ARC FORCE

WELDING VOLTAGE

HOT START

• HOT START ( ): the value previously set.

• WELDING VOLTAGE (

): the measured value of the last volt-

age of what is being previously welded.

• ARC FORCE (

): the value previously set.

To interrupt the HOLD function and go back to the PRESETTING

phase before 15 seconds have passed, simply turn one of the two

ENCODER (E1-E2) knobs.

E2E1

The HOLD function can be terminated ahead of time even once

again starting the welding.

Once 15 seconds have passed (HOLD FUNCTION) the control

panel goes back to the PRESETTING phase.

Loading...

Loading...