19

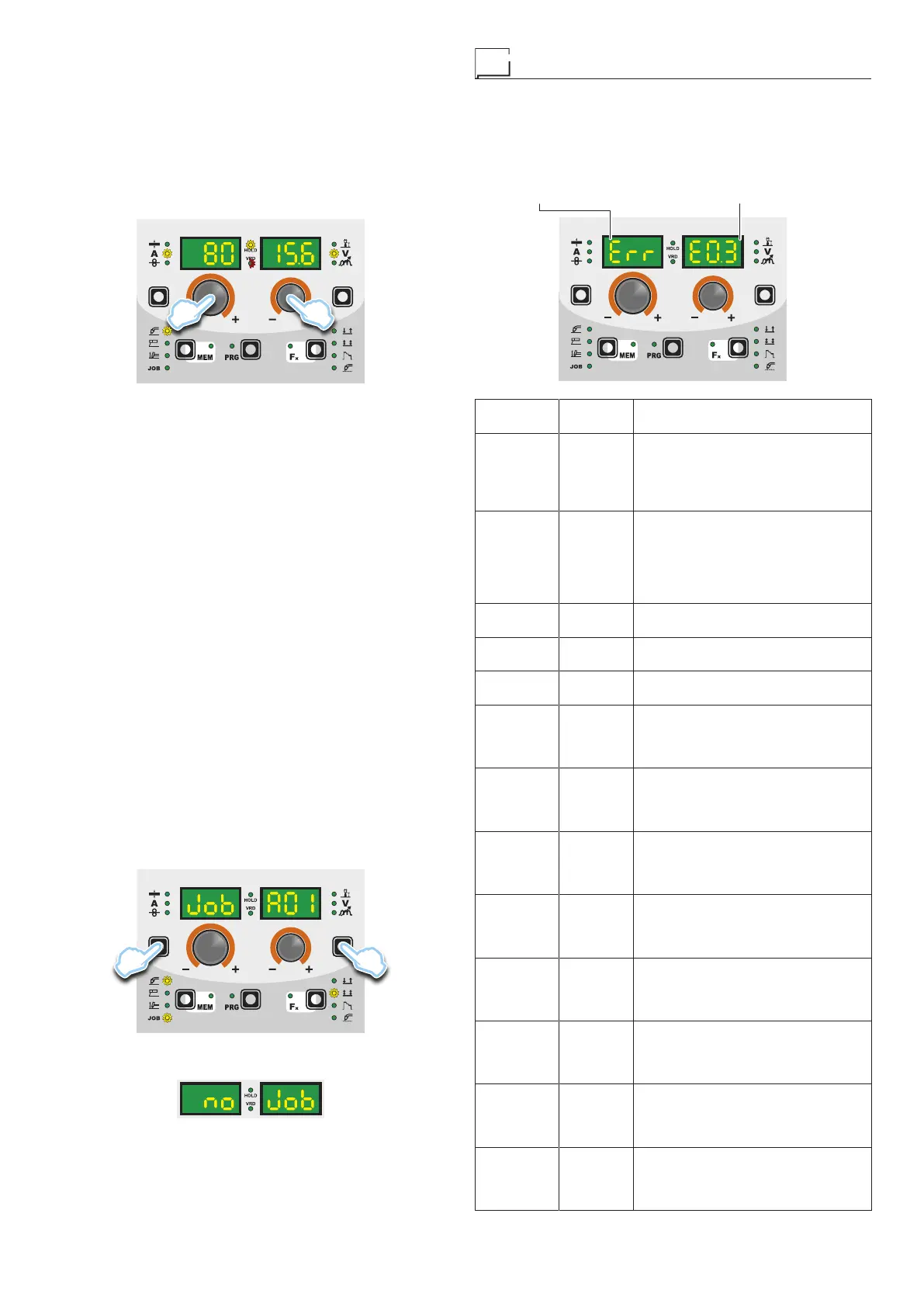

5 - HOLD

This function automatically starts itself at the conclusion of every

welding operation and it is indicated to the operator by means of a

flashing light of the HOLD FUNCTION LED for a specific amount

of time.

Once the welding has been terminated, for about 15 seconds, both

the DISPLAYS should show the same values of the parameters

during the welding.

To interrupt the HOLD function and go back to the PRESETTING

phase before 15 seconds have passed, simply turn one of the two

ENCODER (E1-E2) knobs.

E2E1

The HOLD function can be terminated ahead of time even once

again starting the welding.

Once 15 seconds have passed (HOLD FUNCTION) the control

panel goes back to the PRESETTING phase.

6 - MODIFICATION AND OVERWRITING OF A

MEMORISED JOB

To edit and overwrite a JOB proceed as follows:

1) Select JOB, pressing and releasing, even various times if nec-

essary, the WELDING PROCESS SELECTION key (T2) until

the corresponding LED lights up.

2) Select the individual JOB to modify and overwrite rotating the

ENCODER knob - V (E2).

3) Bring up and activate the JOB, loading its settings in the weld-

ing process it comes from, keeping the SAVE “MEM” key (T2)

pressed for a duration of about 2 seconds.

4) Acquire the parameters necessary for editing the JOB.

5) Hold the SAVE “MEM” key (T2) down for at least 2 consec-

utive seconds until both displays show the flashing wording

that represent the first AUTOMATIC WELDING POINT (JOB)

free and/or available to the operator that can be used for sav-

ing the data.

6) Rotate the ENCODER knob - V (E2) until identifying the indi-

vidual JOB that will be overwritten.

7) Keep pressed, for at least 3 consecutive seconds, the SAVE

“MEM” key (T2) to confirm and make the operation effective.

7 - DELETING A JOB SAVED

In JOB mode, holding down the PARAMETER SELECTION - A

(T1) and PARAMETER SELECTION - V (T4) keys down simulta-

neously for about 5 seconds deletes the current automatic weld-

ing point.

T4T1

The control panel automatically goes to the first JOB saved or

reads “no JOB” is no JOBS have been saved.

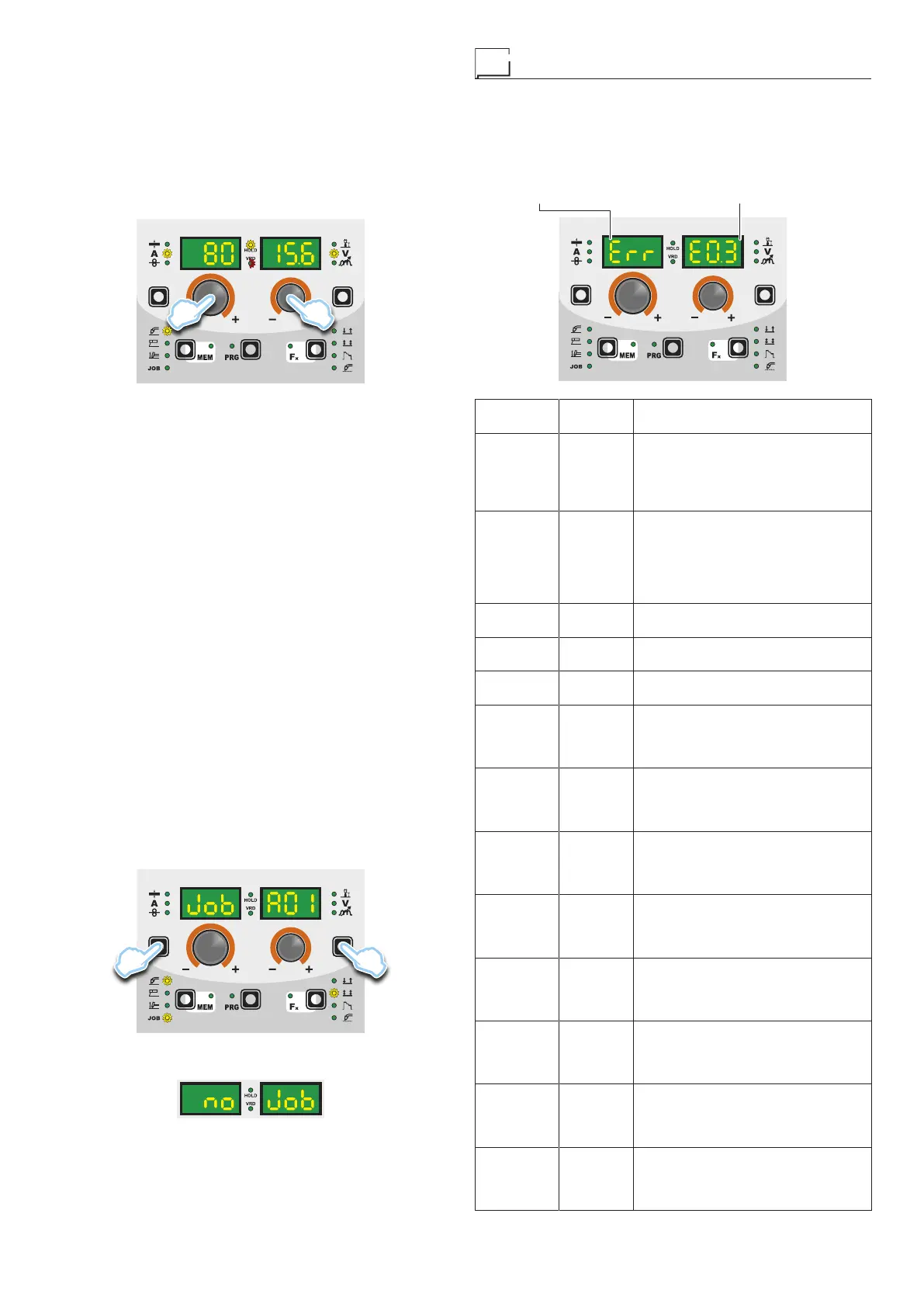

Error condition

This paragraph describes the error conditions that may arise on

the welding machine, the codes and messages shown on both op-

erator interface displays, and the diagnoses for attempting to cor-

rect and resolve them.

In an “error condition” the operator’s interface uses both displays

to display:

▪ ERROR DESCRIPTION display▪ ERROR CONDITION display

Error

condition

Error

code

Error description and possible

diagnosis

Err T°C

THERMAL PROTECTION

The welding stops due to an

excessively high temperature

(thermostat activated).

Automatic reset error.

Err E0.0

POWER SUPPLY FAILURE

NON automatic reset error.

This error can only arise when

switching on and not when the

welding equipment is working

normally.

Err E0.1

OVER AND UNDER VOLTAGE

Automatic reset error.

Err E0.2

OVER VOLTAGE

Automatic reset error.

Err E0.3

UNDER VOLTAGE

Automatic reset error.

Err E0.4

OVER CURRENT

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E1.0

CONFIG. FILE MISSING

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E1.1

USER FILE MISSING

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E1.3

CALIBRATION FILE MISSING

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E1.6

MMA DEFAULTS MISSING

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E1.7

DEFAULTS MISSING TIG

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E1.8

DEFAULTS MISSING MIG

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E1.9

WELDER DEFAULTS MISSING

NON automatic reset error.

Immediately contact technical

assistance dept.

(continued)

Loading...

Loading...