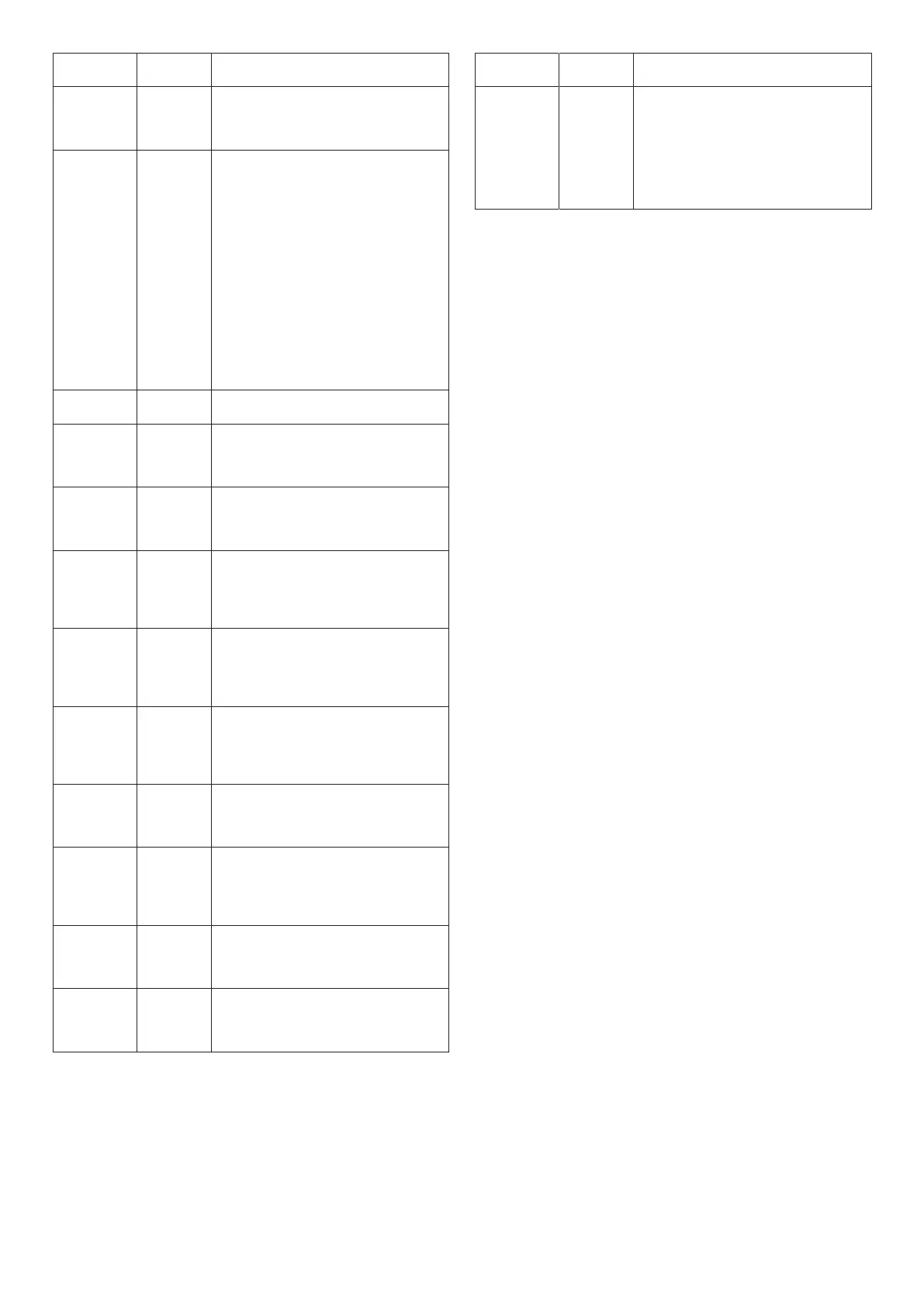

20

Error

condition

Error

code

Error description and possible

diagnosis

Err E2.0

FILE SYSTEM ERROR

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E3.2

STICKING

This error is displayed when a

shortcircuit has been formed

between the machine’s output

terminals for more than 1.2 seconds.

NON automatic reset error.

To remove the error state, eliminate

the short circuit so that the voltage

on the torch goes above the

threshold value again. At this stage

the error condition disappears and

the welding machine goes back to

the mode prior to the sticking. If the

torch trigger is still pushed, it must be

released and pressed again to begin

welding again.

Err E3.4

SCC ERROR

NON automatic reset error.

Err E4.0

LAST SETUP NOT VALID

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E4.1

JOBS WRONG

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E4.2

MIG SYN SPECIAL FUNCTION “Fx”

WRONG

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E4.3

MIG MAN SPECIAL FUNCTION “Fx”

WRONG

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E4.4

SPECIAL “Fx” PULSED MIG

FUNCTIONS NOT VALID

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E5.0

MIG PROGRAMS MISSING

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E5.1

NO PULSED MIG WELDING

PROGRAMS

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E5.3

PROGRAMS MISSING

NON automatic reset error.

Immediately contact technical

assistance dept.

Err E5.4

NO WELDING PROGRAMS

NON automatic reset error.

Immediately contact technical

assistance dept.

(continued)

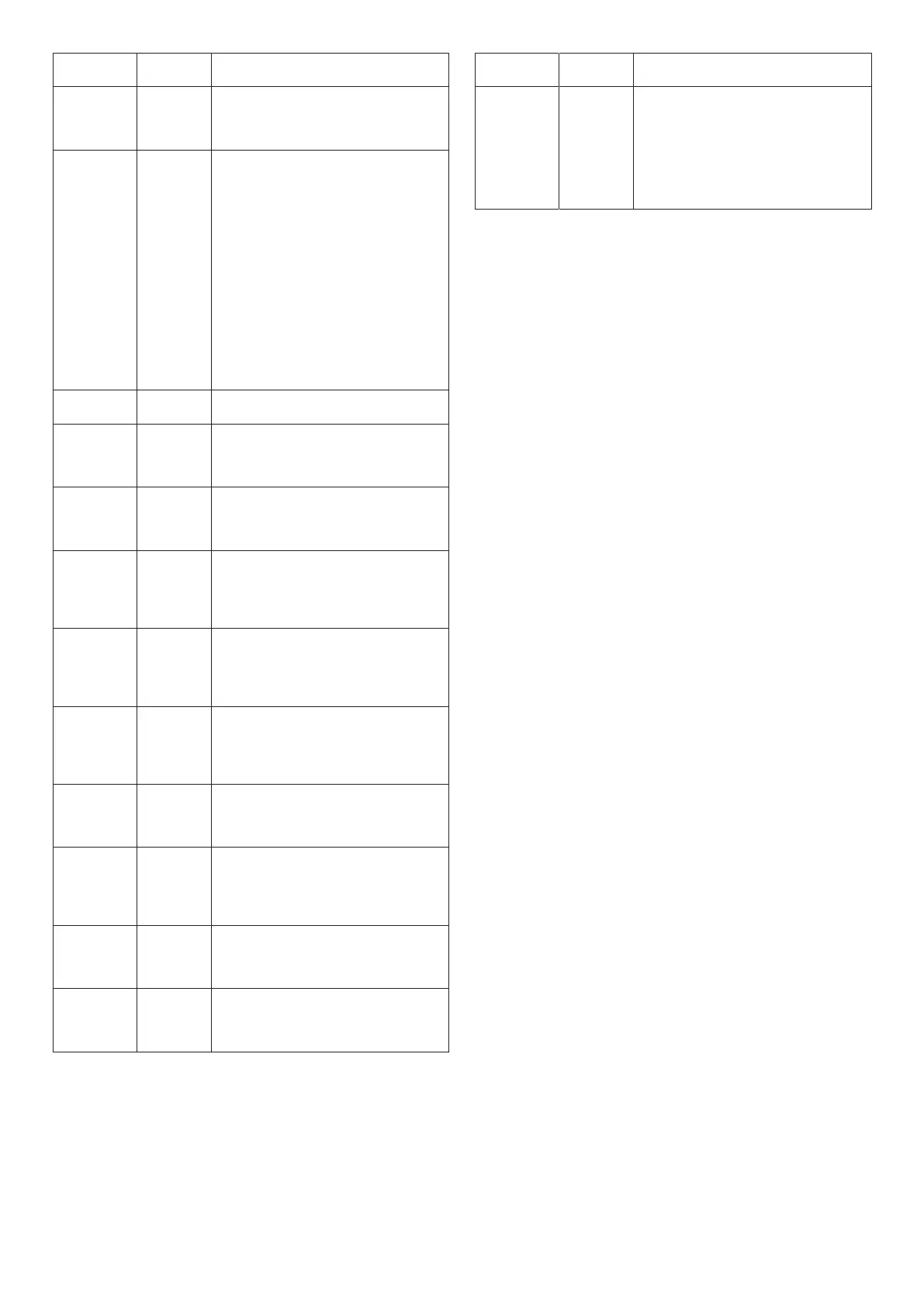

Error

condition

Error

code

Error description and possible

diagnosis

AUT ADJ

POWER LIMITATION

This alarm appears if the power limit

is exceeded. The alarm alternates

with the standard display every 1.5

seconds, despite which the machine

continues to weld, supplying limited

power, but complying with the values

shown on the data plate.

The table includes 2 types of errors:

• Automatic reset error: Once the alarm condition has been re-

solved the welding machine starts working again and the oper-

ator can weld again!

•

NON automatic reset error: To remove the alarm status and

reinstate correct operation of the machine, the welding equip-

ment must be switched off.

The machine will then be working again and the operator can

weld again!

PLEASE NOTE: If, when switching on, the error status pre-

sents itself again, immediately contact the Technical Assis-

tance Department.

This is necessary so that our technical assistance dept (that must

be contacted each time the error messages appear on the

welding machine’s operator interface) is able to resolve the

problems more easily and as quickly as possible, thanks to the re

-

ports by the user, and also because, in the meantime the welding

machine does not allow the operator to do their work.

Loading...

Loading...