63

QC Standards

Requires part number 523010 (optional accessory)

For best results, please ensure your ORACLE has been

properly setup and has passed all diagnostics tests prior

to completing the QC Standards test calibration.

The QC Standards test is designed to help ensure your

ORACLE results stay within specification across a range of fat

levels. This test must be calibrated using four standards

containing different amounts of oil (nominally 10, 20, 50,

and 80 %) which are designed to mimic the fat content of

actual food samples. The calibration procedure takes

approximately 90 minutes, and consists of three phases

whereby each standard is analyzed three times in order to

obtain the most accurate results.

Each set of standards are designated with a serial number to

ensure facilities with multiple standards do not accidentally

use the incorrect standard to produce a false failure. Ensure

all four Standard tubes have matching serial numbers before

each analysis.

In addition to the QC Standard Tubes, the Normalization

tube provided with every ORACLE must be tested.

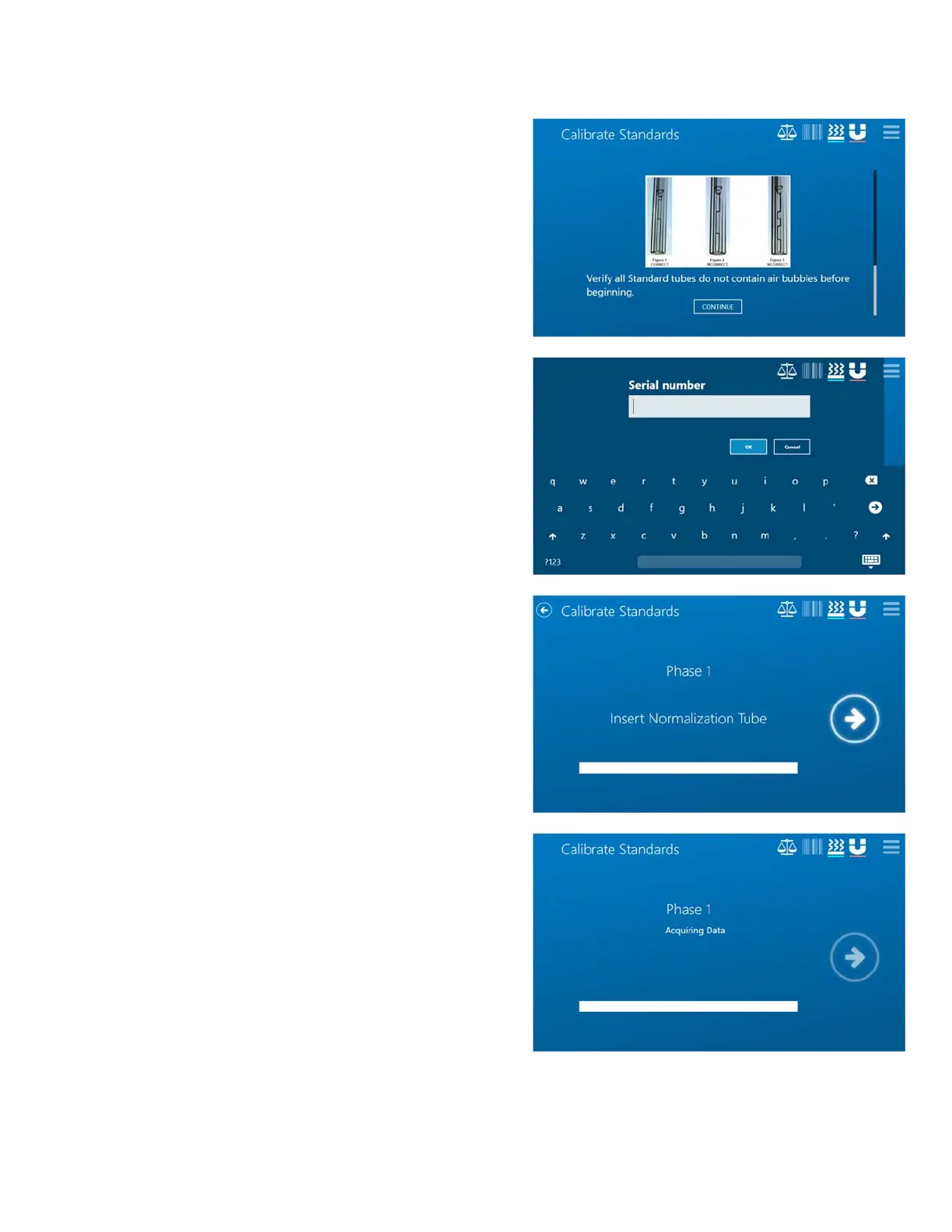

To analyze the QC Standards, first ensure all four tubes have

been temperature conditioned in the heater block for a

minimum of 1 hour. For initial setup and future maintenance

tests, simply follow the instructions on screen to add each

individual tube for a brief analysis, upon which the ORACLE

software will label the results as passing with a green check,

or failing with a red X. In the event of a failure, please follow

the instructions in this manual for running the Diagnostic

Tests, then contact CEM’s service department.

Loading...

Loading...