30

Components & Systems Product Manual - Orca

™

CO

2

Series MicroBulk Delivery System

The push button controls allow the operator to start and stop

the delivery, to view information, initiate the print out of the

delivery ticket and to clear the total.

Note: If programming assistance is required,

refertoFlowcommanualorcontacta

technical service representative at Chart

Inc.at1.800.400.4683.

Note:SeetheFlowcommanualsforpreference

changes such as date, time, units of

measure,printingoptions,password

settings, etc.

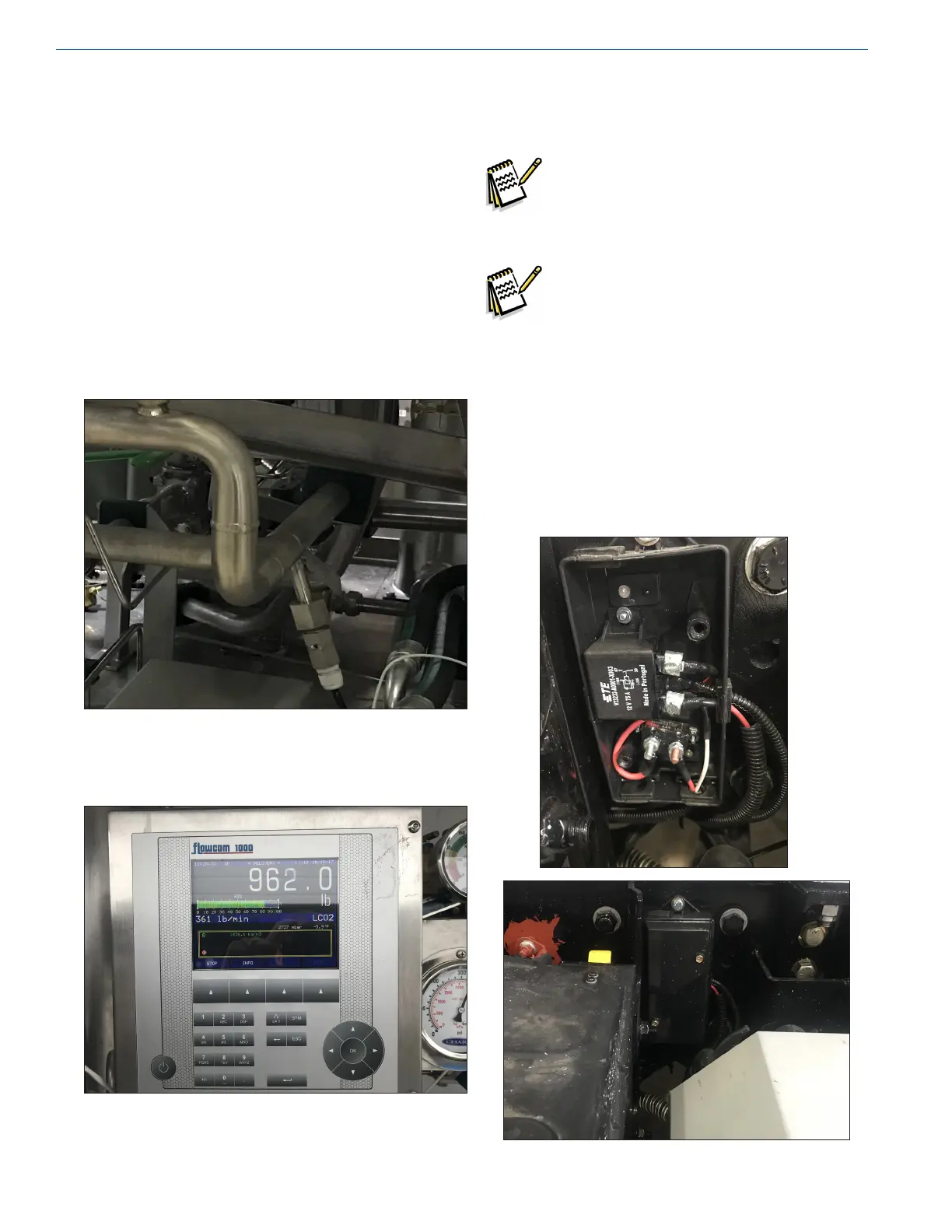

Cabinet Power - Truck

Power to the worklights and Flowcom comes from the 12

volt junction box near the battery box. Within the junction

box is a relay that is energized with the truck key in the

ON or ACC position, providing cabinet power. The 10-amp

breaker protects the circuit.

These are Rosemount Pre-Set Dierential Pressure

Transmitters used on the Orca system. They are connected

to the meter section and the Flowcom meter system. The DP

transmitters measure a change in pressure (pressure drop)

across the meter section and relay this information to the

Flowcom meter system in a 4-20 milliamp signal.

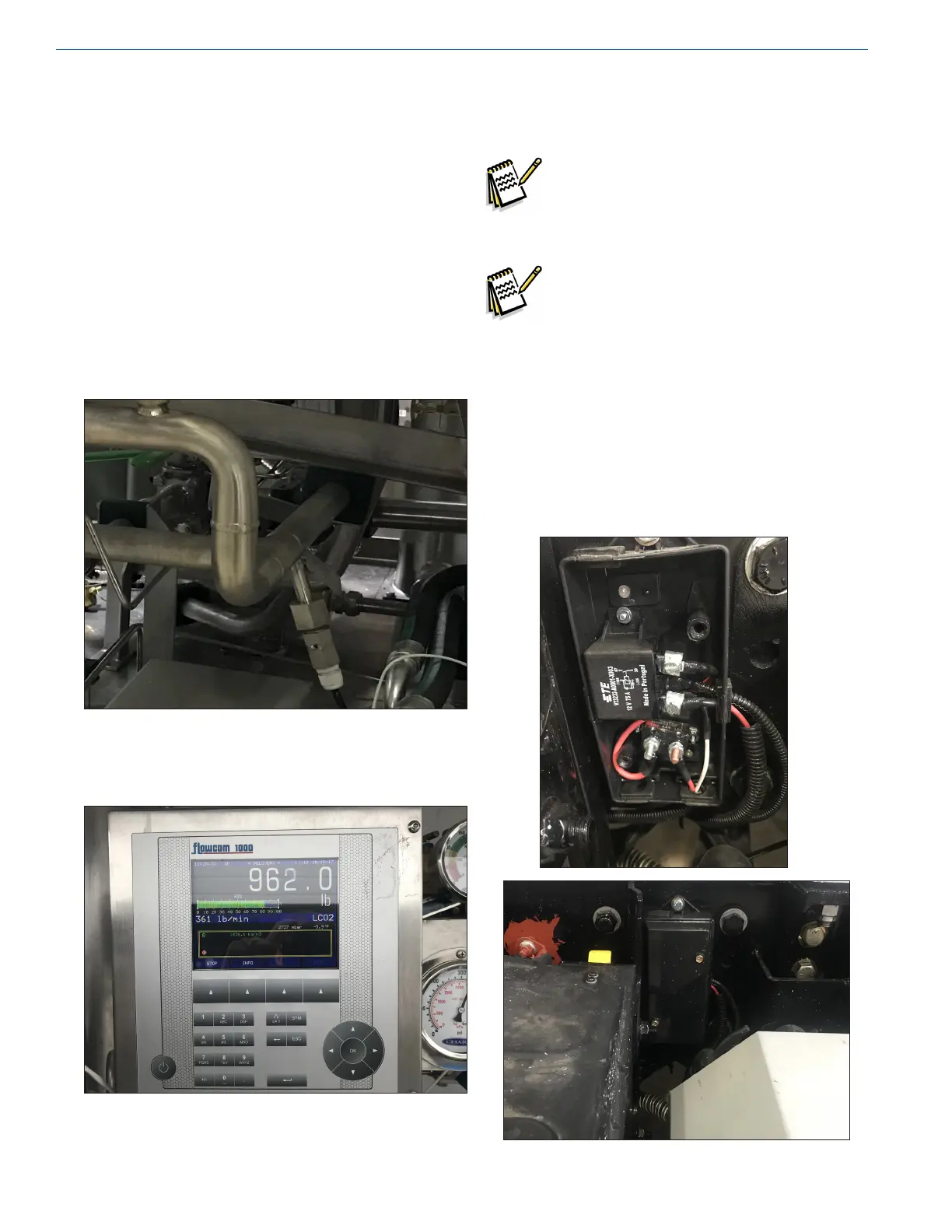

RTD - Resistance Temperature Device

The resistance temperature device (RTD) is located upstream of

the meter. The probe is threaded into a port so it can accurately

measure the temperature of the liquid. The resistance of the

element at the end of the probe varies with temperature. The

RTD is used to measure accurately the temperature of the liquid

being metered. Based on this temperature, a density is assigned.

Flowcom Flow Meter System

The Flowcom

®

Flow Meter System is used for calculating,

integrating, system controlling, and displaying the mass ow.

Loading...

Loading...