40

Troubleshooting Product Manual - Orca

™

CO

2

Series MicroBulk Delivery System

Error Codes & Warnings

During the switch-on phase, the Flowcom

®

Flow Meter System checks the important system functions and

the data integrity. The dierentiation is made between errors and warnings. Warnings and errors that can be

addressed can be conrmed. The device can then be operated further. In the event of errors that cannot be

addressed, the “DELIVERY” function is blocked. Errors and warnings are displayed during the switch-on phase.

Sections referenced below refer to the Flowcom 3000 Service Manual. See the Service Manual for more

information.

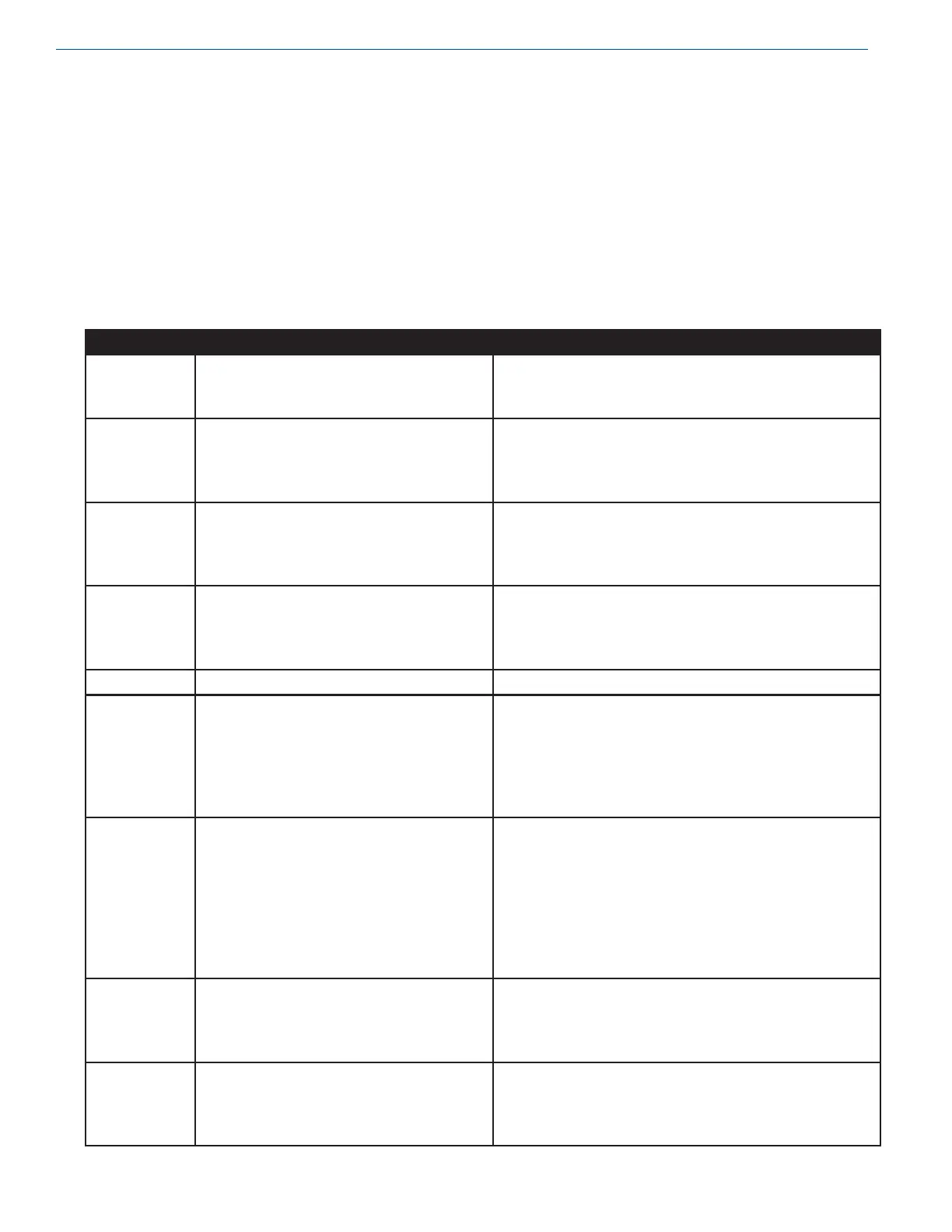

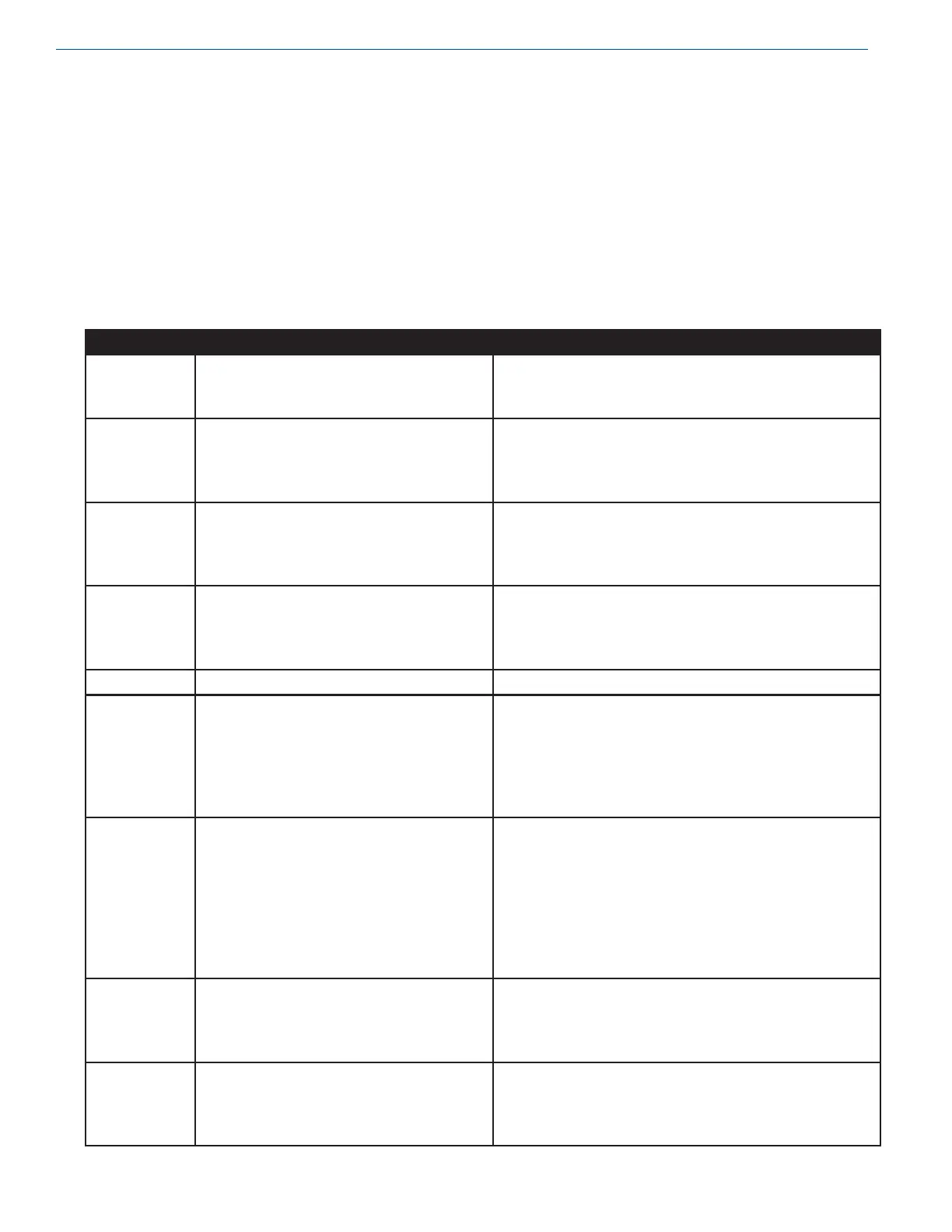

Overview of Error Codes

Error Cause Task

E001 Hardware calibration not yet carried out.

Checksum error identified when reading

the calibration data.

Perform hardware calibration. (See section 3.2.8,

“Hardware calibration”). The calibration seal needs to

be broken.

E002 Parameters for configuration of the

meter system have not been entered yet.

Checksum error identified when reading

the corresponding settings.

Configure device. See also section 6 “Parameters.

Settings.”

The calibration seal needs to be broken.

E003 Parameters for calibration of the meter

system have not been entered yet.

Checksum error identified when reading

the corresponding settings.

Calibrate metering system or enter calibration data. See

section 6 “Parameters/Settings.”

The calibration seal needs to be broken.

E004 User settings #1 of the meter system have

not been entered yet.

Checksum error identified when reading

the corresponding settings.

Configure device. See also section 6 “Parameters/

Settings.”

The calibration seal does not need to be broken.

E005 - E007 A new mother board has been installed Confirm error.

E009 - E010 Measured temperature is too low.

PT 100 low signal voltage.

PT 100 excitation current out of range.

Broken cable.

May be caused by any of the following:

-Temperature sensor PT100 is not connected properly.

-Temperature range switching is defective.

-Constant current source is defective.

-The product parameter does not match the actual

product being metered.

Boot-up errors

E011 - E015

-Liquid flow through meter section before

meter is turned on.

-DP Transmitter defective

-Wiring defective

-Leak in DP lines

-Press “STOP” button on control pendant

-Verify transmitter is plugged into junction box JB1, and

that wires are not broken.

-Voltage across contacts 1 & 2 on block X7 should

measure between 18 & 26 VDC. If not, front board

needs to be replaced.

-Tighten fittings.

E030 User settings #2 of the meter system have

not been entered yet.

Checksum error identified when reading

the corresponding settings.

Configure device. See also section 6 “Parameters/

Settings.”

The calibration seal does not need to be broken.

E031 PumpSmart settings of the meter system

have not been entered yet.

Checksum error identified when reading

the corresponding settings.

Configure device. See also section 6 “Parameters/

Settings.”

The calibration seal does not need to be broken.

Loading...

Loading...