39

TroubleshootingProduct Manual - Orca

™

CO

2

Series MicroBulk Delivery System

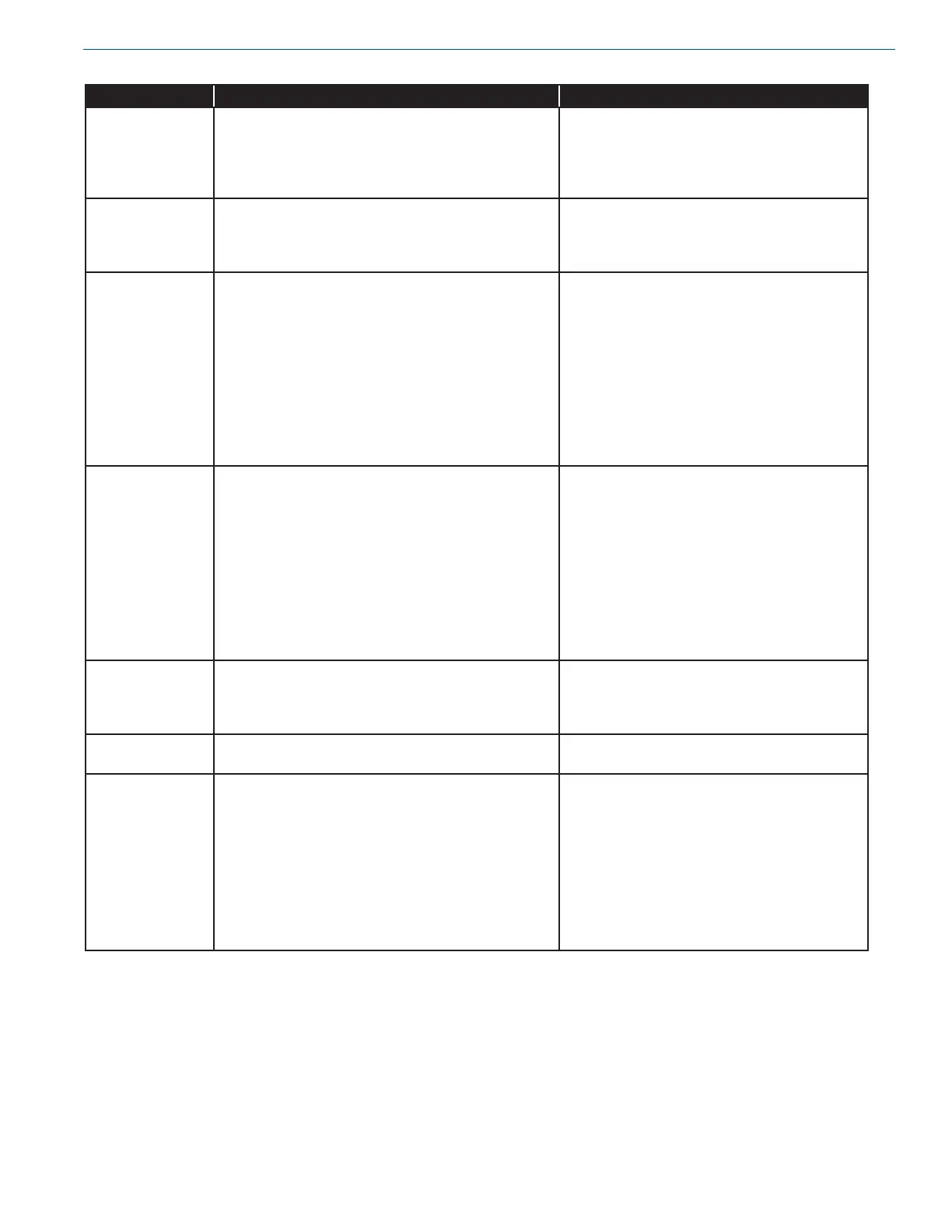

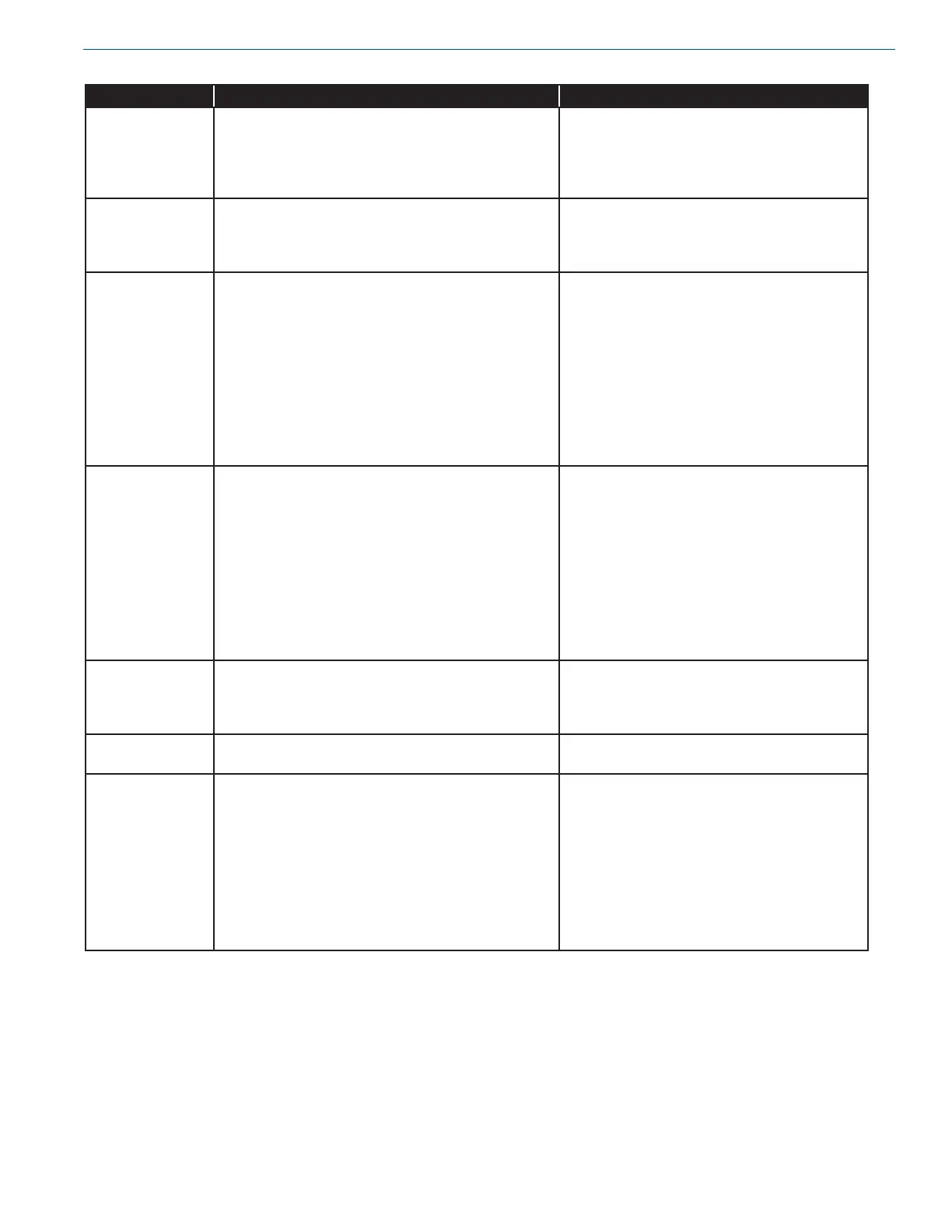

Symptom Possible Cause Remedy

Tank builds excess

pressure or builds

pressure too fast

Low usage

Tank is over-filled

If daily usage is less than the NER, the tank will

build pressure.

If the tank is filled past the vent trycock or past

the DOT specified fill weight, the pressure may

rise rapidly after a fill

Tank pressure is

too low or does not

build pressure at a

sufficient rate

Tank is leaking. Check for frost anywhere on the plumbing or

near the pressure reliefs. Spray soap solution on

joints to test for leaks. Repair leaks if possible

otherwise call Chart for assistance.

Tank is contaminated with moisture or CO

2

byproducts. Contaminants such as water will freeze in

solution with liquid CO

2

preventing adequate

flow of product into the pressure building coil.

After the tank has been emptied, purge the tank

with 50°C - 100°C nitrogen for 12 hours or more.

Purge CO

2

byproducts out through the liquid fill

line. After donning safety glasses and gloves,

place a rag over the fill line outlet and open the

valve briefly. Inspect the cloth for discoloration

or impurities. Repeat until all impurities are

removed.

Carbon dioxide ice in tank If the pressure in the tank drops below 61 psi, dry

ice slush will form in the tank which will restrict

liquid CO

2

from entering the pressure building

coil. To liquefy solid CO

2

, pressurize the tank

using an outside source to 300 psi. Each pound

of frozen CO

2

will consume one pound of dry CO

2

gas. For example, if the unit had 50 pounds of

solid CO

2

, it would consume the contents of one

50 lb high-pressure cylinder. Liquefaction is a

slow process. It takes 30 minutes to liquefy each

pound of solid CO

2

.

Frost occurs

around the

plumbing

Tank is being used

Frost is residual from last fill or earlier use

This is normal if the tank is receiving or delivering

CO

2

.

This is normal. Frost may remain on the plumbing

for hours after a fill or heavy use.

Frost occurs on

hose or hose reel

Residual frost from last fill or recent use This is normal. Ice may remain for hours after a

fill or heavy use.

Flow meter not

working

Water ice in phase lines to transmitters

Carbon dioxide ice in phase lines to transmitters

If any moisture is found in the CO

2

supply, it

will make its way to the DP transmitter phase

lines and immediately block them. To purge the

moisture, remove each phase line and force warm

nitrogen through them.

To avoid dry ice forming in the DP transmitter

phase lines, pressurize the metering section with

CO

2

gas above 70 psi before introducing liquid

CO

2

.

Loading...

Loading...