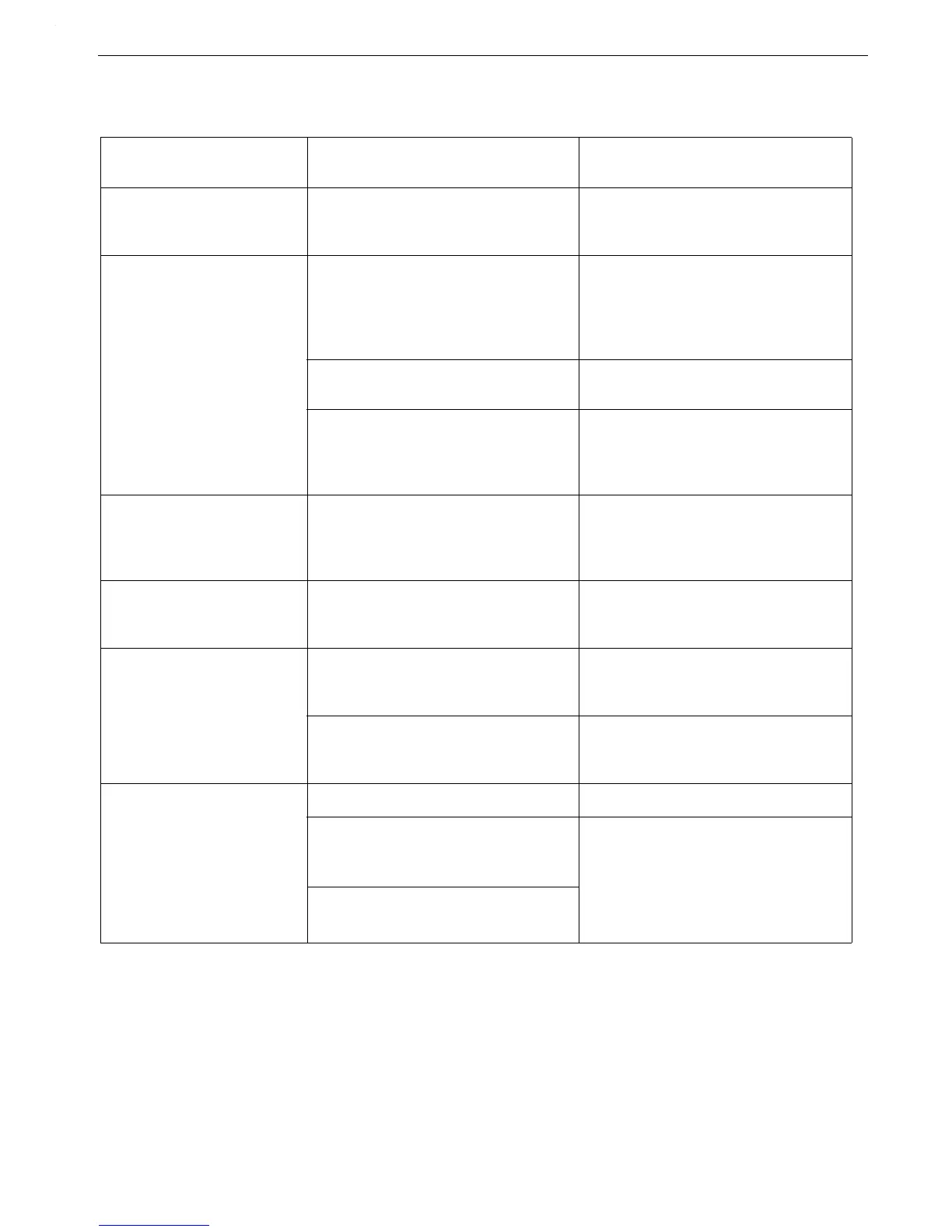

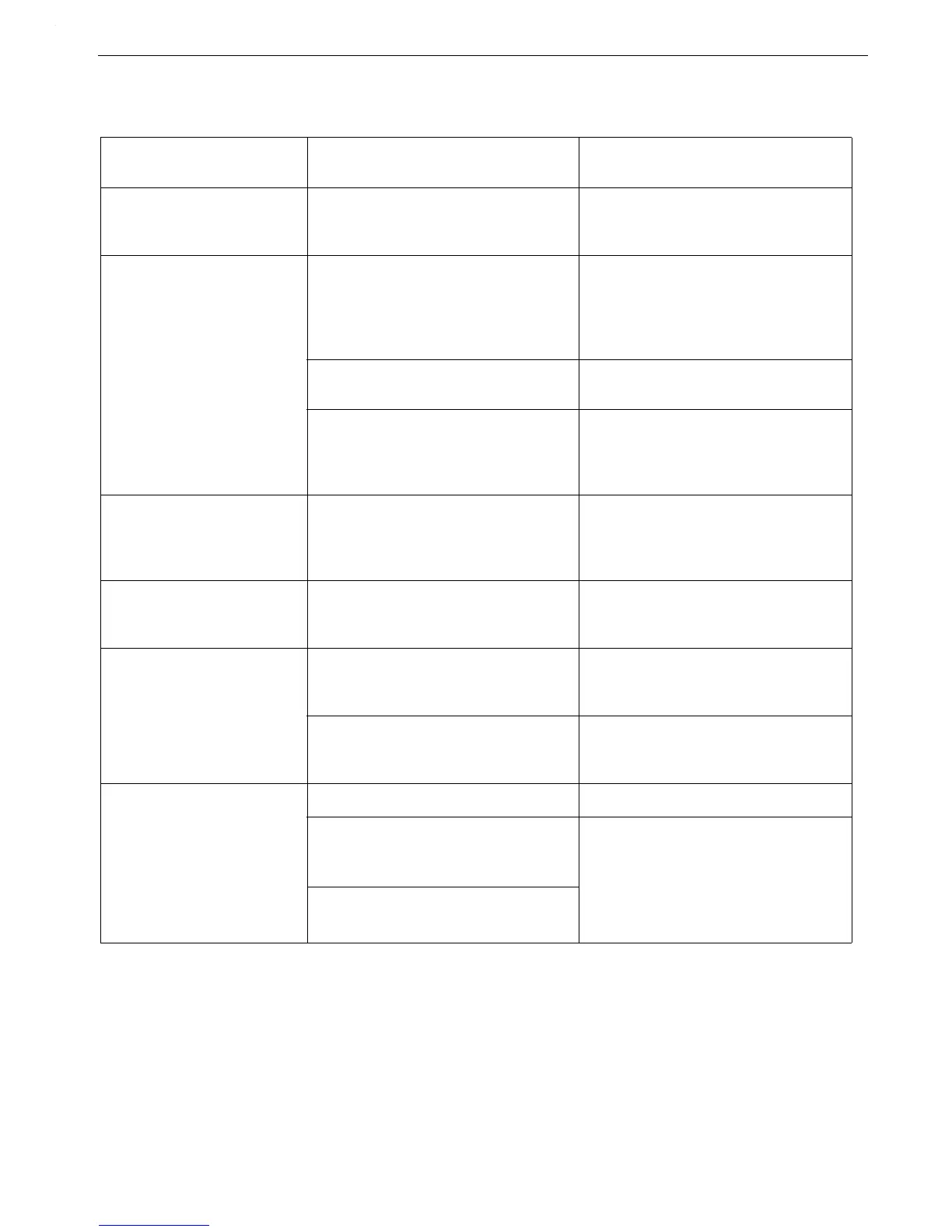

Auger wears holes in

tubes.

Auger kinked or poorly brazed. See Auger Brazing section in this

manual

Elbows wear out. Auger is stretched too tight; hori-

zontal L.H. turn; auger has been

run dry.

Lengthen auger; Install an Exten-

sion Hopper; wire Boot Switch

into system.

Excessive auger vibra-

tion and noise.

System has been operated too

often without feed (auger has

scored the auger tubes).

Wire a Boot Switch to stop the

system when the feed bin is

empty; replace damaged auger

tubes; be sure auger has proper

amount of stretch.

Tubes inadequately supported. Support the tubes every 5’

(1.5 m) or closer.

Horizontal L.H. turn. No outlet drops on or just before

an elbow; lengthen the auger;

install an Extension Hopper

ahead of elbows.

Fill system short cycles. Control end feed level switch

does not provide large enough

feed differential.

Use a time clock to program

operating cycles. Use Control

end feed level switch w/lockout

and time clock.

Extension Hopper packs

full of feed.

Both switches on Extension Hop-

per are out of adjustment.

Adjust switches as specified in

maintenance section in this man-

ual.

Second portion of

extended length system

will not start.

Lower switch on Extension Hop-

per out of adjustment.

Adjust switch as specified in the

maintenance section of this man-

ual.

Feed level control at end of line

out of adjustment.

Examine and make necessary

adjustments; see feed level

switch adjustment instruction.

Second portion of

extended length system

short cycles.

Too much Restrictor in the Boot. Shorten Restrictor.

Too much feed is still dispensing

from drops ahead of Extension

Hopper.

Trim Restrictor on first portion to

allow more incoming feed.

Last outlet drop before Extension

Hopper must have full feed drop

out. NOTE: All feeders ahead of

hopper must complete filling

before feed reaches hopper.

Loading...

Loading...