Installation Model 55,75,90, & HMC FLEX-AUGER

24

MA1702D

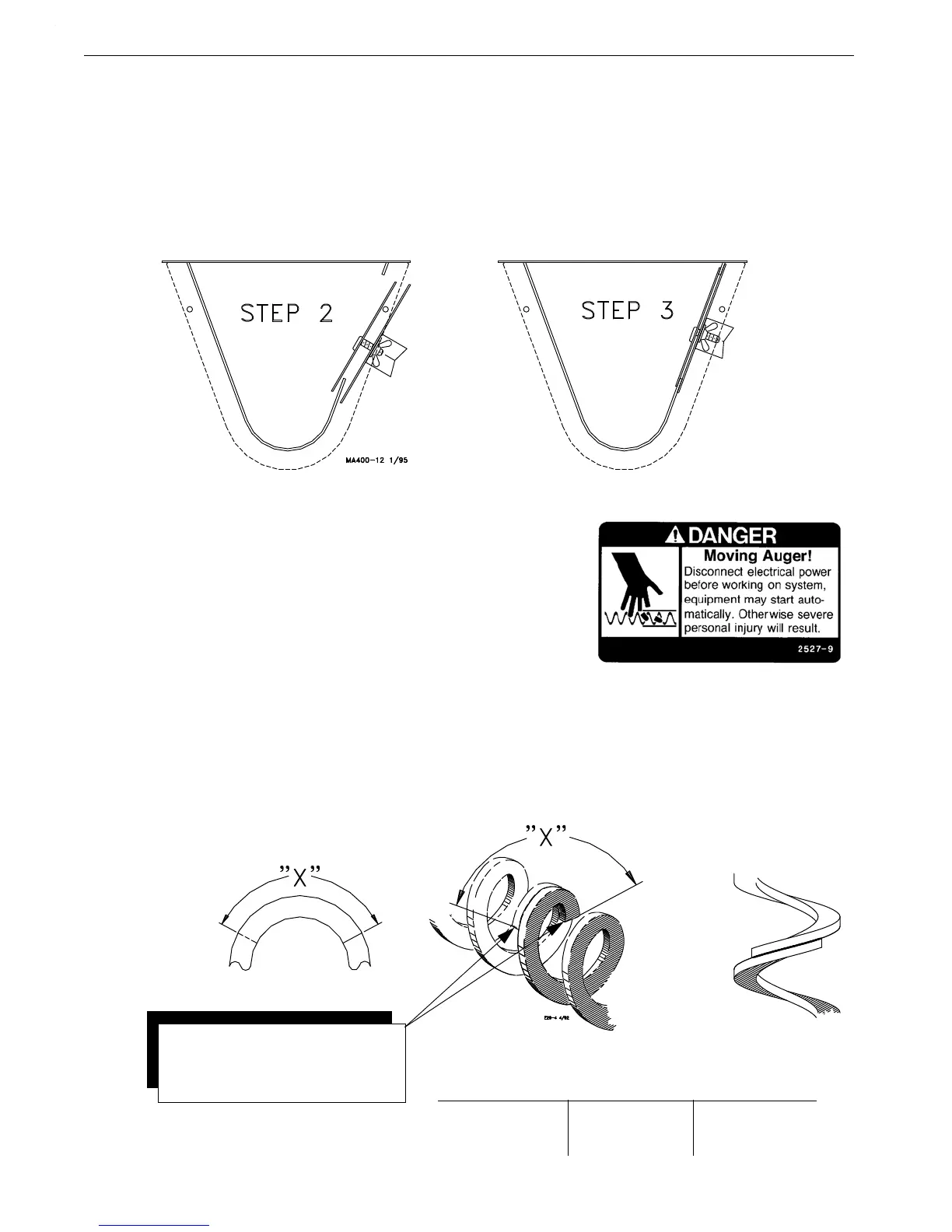

Cover Plate Installation

The cover plate is installed after installation of the auger in the tube (See Figure 24).

To install the cover plate:

1.Loosen wing nuts to end of studs

2.Start lower side of cover plate in boot opening.

3.Slide the cover plate up as far as possible so that plate catches top of boot opening.

4.Hold the cover securely while tightening the wing nuts.

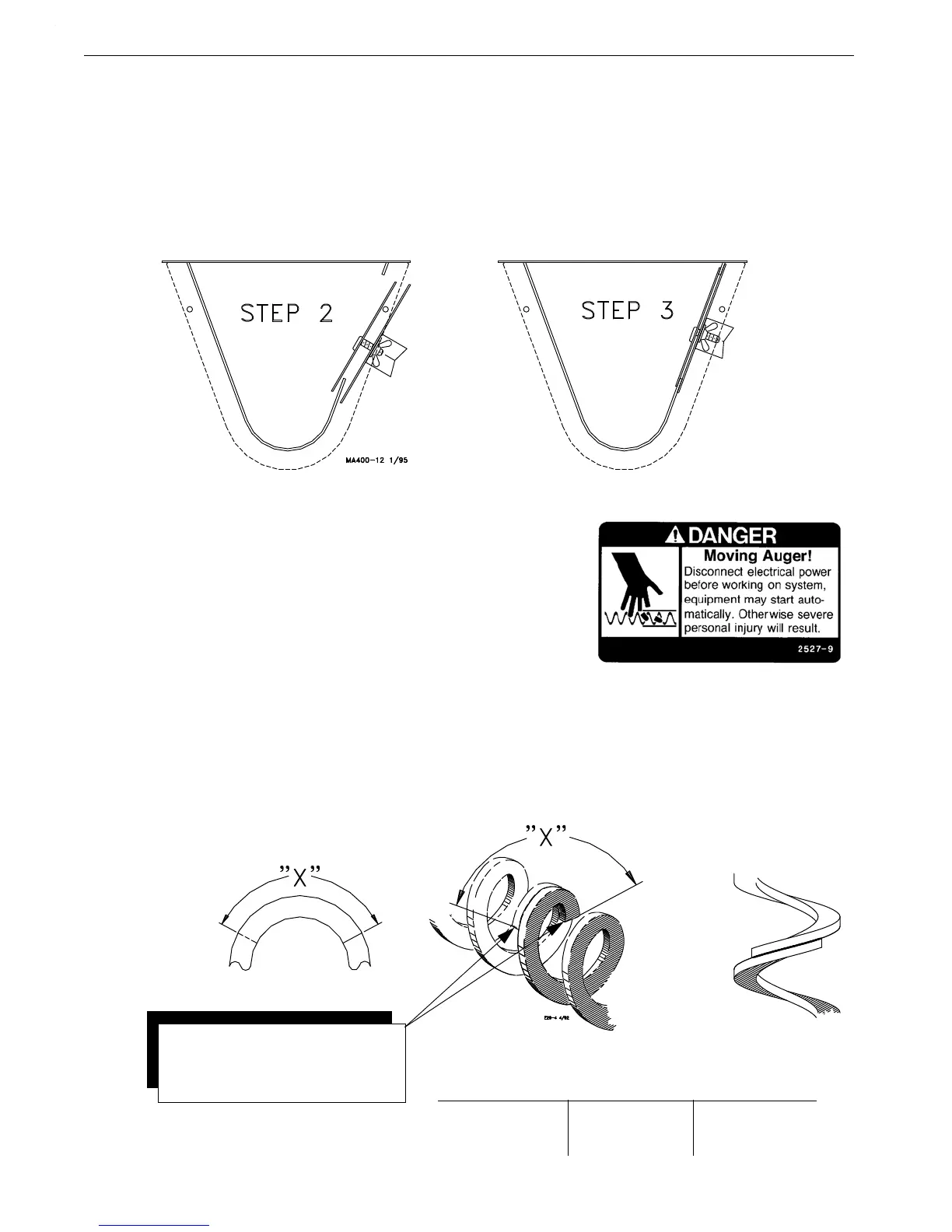

Auger Brazing/Filing

If the auger needs to be spliced or lengthened, locate the brazed joint

closer to the power unit to minimize feed flow restriction in the line.

To align the auger for brazing, lay it in angle iron and clamp securely.

Rotate the auger to allow both the inside and outside edges of the augers

to be brazed.

Butt the ends of the auger against each other. DO NOT SCREW ONE

AUGER INSIDE THE OTHER--This restricts the feed flow.

Figure 25 and the associated chart specify how far to lap the augers.

A bronze, flux-coated rod is recommended. The joint should be well filled and smooth so that it does not wear

against the tube. Allow the joint to air cool.

File the auger edges, as shown in Figure 25, to avoid damage to the auger tubes. Also, file off any brazing that

extended beyond the outside radius of the auger flightings.

Figure 24.Cover Plate Installation

System

Model Model Model

55 Auger 75/HMC Auger 90 Auger

1.0 to 1.13” 1.5 to 1.75” 1.5 to 1.75”

(25 to 29 mm) (38 to 45 mm) (38 to 45 mm)

X=

Note: Sharp Auger Ends at the

to avoid damage to Auger Tube(s).

braze(s) must be filed or ground

Figure 25.Auger Brazing/Filing

Loading...

Loading...