Model 55,75,90, & HMC FLEX-AUGER General Information

7

MA1702D

Selecting the System

CHORE-TIME Feed Delivery systems are designed to handle most common livestock and poultry feeds. We can

not guarantee satisfactory operation with all formulations. We suggest that you contact our Technical Service

Department concerning the use of new or unusual formulations.

FLEX-AUGER Feed Delivery Systems are the most versatile feed conveying systems available. Their ease of

installation, reliability, low maintenance, and adaptability for many different applications, make them an

indispensable part of any livestock feeding system.

The FLEX-AUGER Feed Delivery System you choose should be based on the following;

1.Particle Size - Feed particles that are too large for the system will cause damage to the particles, excessive

power requirements, and plugging of the system.

2.Moisture Content (18% maximum) - The moisture content of the feed, among other factors, determines the

amount of buildup that will occur on the auger and auger tubes when conveying feed. Feeds with high

moisture content (above 18%) will freeze if exposed to freezing temperatures. This type of feed tends to flow

less-easily causing higher power requirements. Feeds in High Moisture Corn applications should not exceed

27% moisture content.

3.Feed capacities - Each size of FLEX-AUGER delivers feed at a different rate. These rates should be matched

to your feed requirements. An application that requires a large volume of feed to be moved should use a

larger (i.e. Model 90 or HMC) auger system or possibly two smaller auger (i.e. Model 55 or 75) systems. See

below for System Comparison information.

4.Running Time - Size the system so that the maximum operating time is four hours per day (24 hours). If

necessary, refer to “Livestock and Poultry Feed Consumption” on page 53. If your system operating

times exceed four hours per day, contact your distributor or Chore-Time’s Technical Service Department.

NOTE: The maximum allowable liquid molasses content for all FLEX-AUGER Feed Delivery Systems is 2%.

At higher liquid molasses content or at moisture levels above the recommended limits, the auger tubes can become

coated. This reduces the carrying capacity of the feed delivery system, causing eventual plugging of the system.

Commercial layer applications require the use of all steel FLEX-AUGER Feed Delivery Systems. Hardened steel

elbows are required for these applications. This is due to the abrasive feed particles in commercial layer feed

rations. Do not mix steel and PVC components within a system.

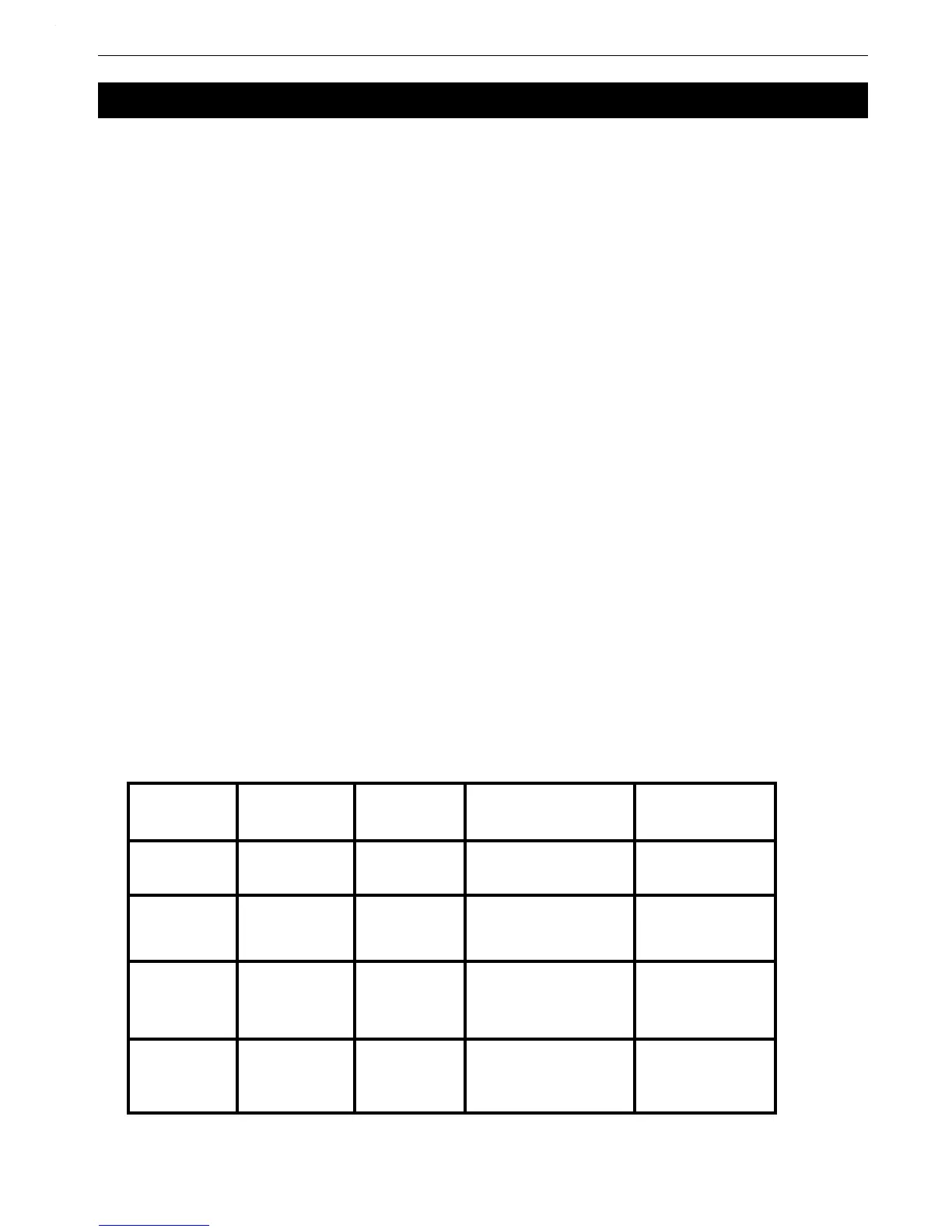

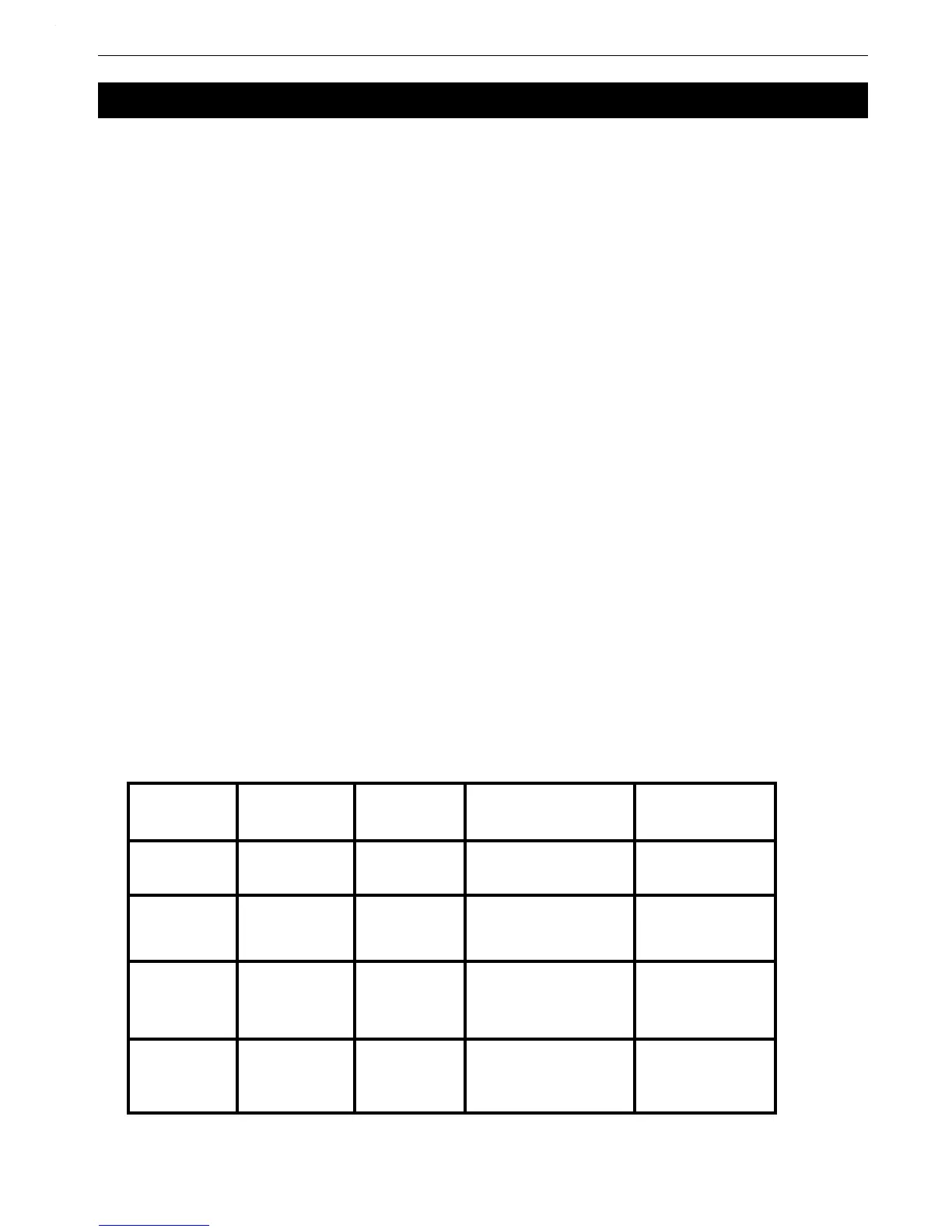

System Comparison Chart

General Information

System Tube Dia. Delivery Feed Types Max. Part.

Rate* Size

Model 55 2-1/4” 15 lb/min. mash, crumbles 1/8” x 1/2”

(55 mm) (7 kg/min.) 18% moist. content (3 mm x 13 mm)

Model 75 3” 50 lb/min. mash, crumbles 1/8” x 1/2”

(75 mm) (22 kg/min.) 18% moist. content (3 mm x 13 mm)

Model 90 3-1/2” 100 lb/min. mash, pellets, 3/16” x 1/2”

(90 mm) (45 kg/min.) shelled corn (5 mm x 13 mm)

18% moist. content

Model HMC 3-1/2” 50 lb/min. high-moisture corn, 3/8” x 3/4”

(90 mm) (22 kg/min.) larger pellets,crumbles, (10 mm x 20 mm)

mash 27% moist. content

*Conveying capacity is based on feed with 40 pounds per cubic foot (640 kg. per cubic meter) density.

Conveying capacities for all the FLEX-AUGER Systems are determined using 348 RPM Power Units.

Loading...

Loading...