Model 55,75,90, & HMC FLEX-AUGER Installation

15

MA1702D

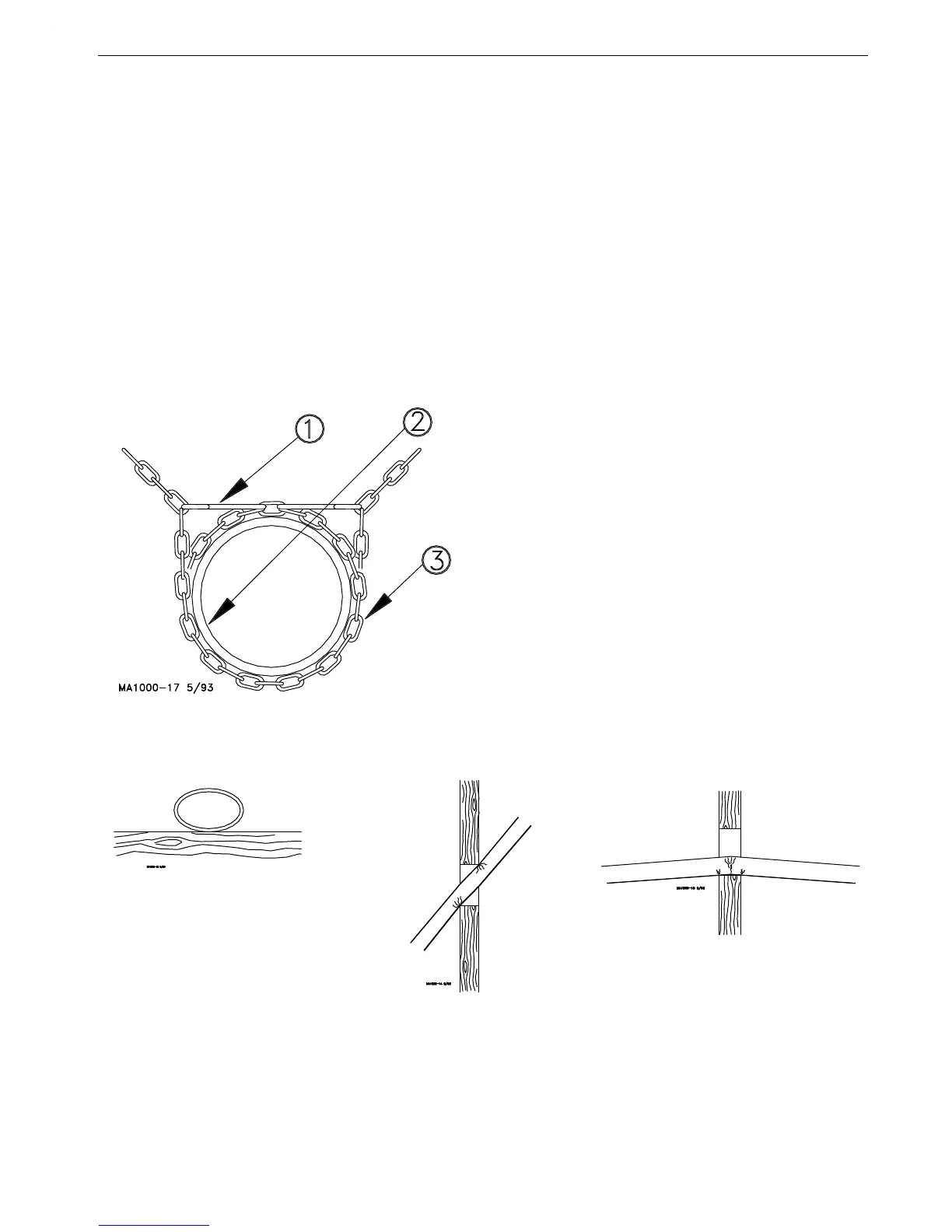

Supporting the System Inside the Building

Support the Auger Tubing with chain and "S" Hooks every 5 feet [1.5m]. Steel Tube systems require support every

10 feet [3m]. The system should be restrained from swinging by using chain and "S" hooks to brace the auger tube,

every 20 feet [6m], as shown in Figure 7.

Horizontal elbows need to be supported in at least two places. Chain, screw hooks, and "S" hooks are supplied as

a suspension kit for supporting the equipment. Keep the line as level and straight as possible.

If Drop Feeders, Extension Hoppers, Outlet Drops with long angled Drop Tubes, or other loads are imposed on

the system, extra support will be required.

Power Units require extra support to resist the twisting encountered when the motor starts and stops. Use the motor

mount base, all of the "ears" on the gearhead as well as the suspension point provided on the 46800 Control Unit

Box to support the Power Unit.

Adequate chain and "S" hooks are provided with each system to properly support it. Other means of supporting

the system are permissible as long as the system receives the correct support and the auger tube is not dented or

flattened. Alternative support systems must allow for expansion and contraction of the Auger Tubes.

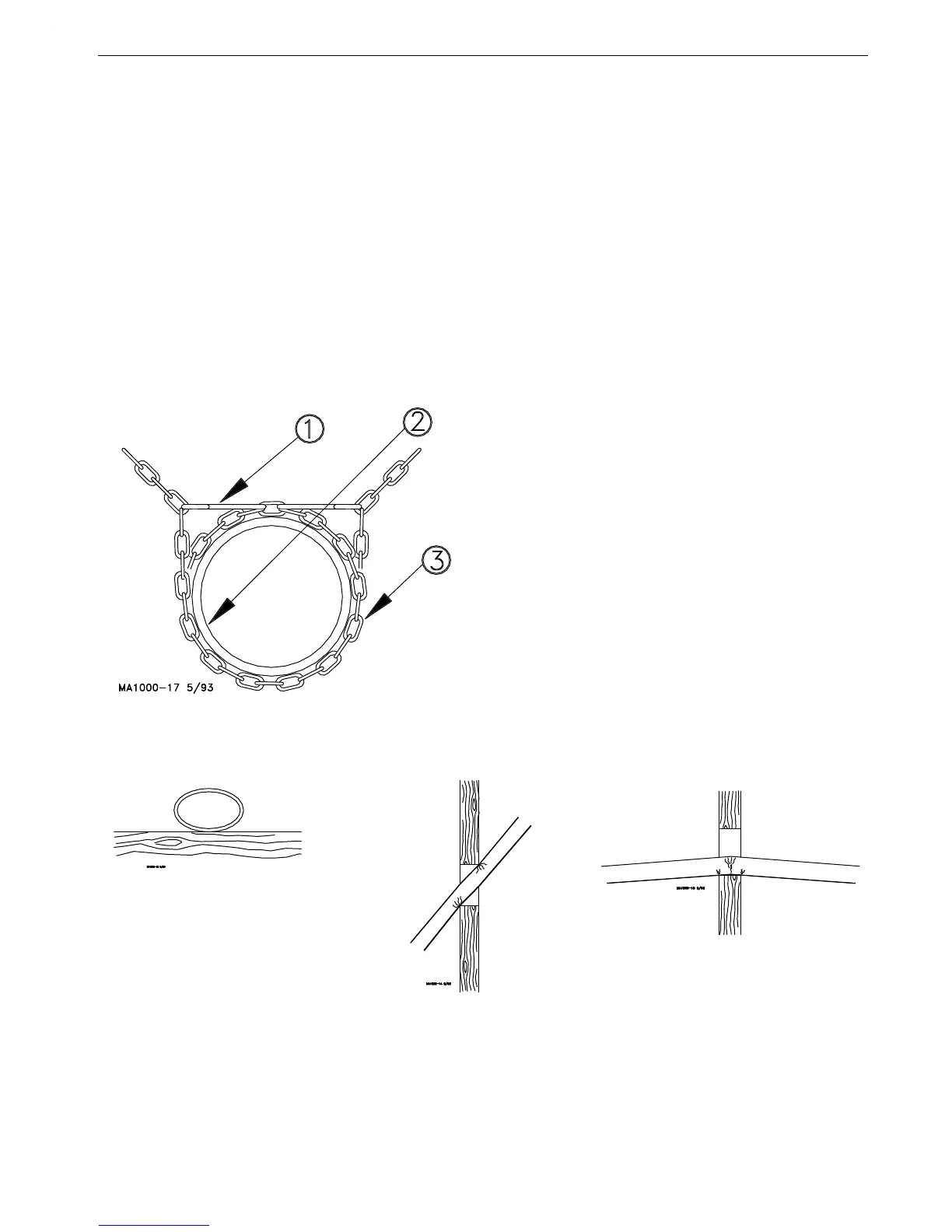

When the auger tube passes through a side wall or partition, especially where it enters the building, the opening

should be made large enough so the auger tube can be supported without resting on the wall. If the auger tube rests

on the wall or partition, the auger tube may flatten out or become kinked--causing excessive wear. (See Figure 8).

Key Description

1 “S” Hook

2 Auger Tube

3 Chain

Figure 7.Proper Auger Tube Connection

Auger tube flattened

because the supports are

not high enough to keep

the weight of the auger

tube off the wall.

Auger tube pinched because

the Auger Tube is not in line

with the hole in the Wall.

Auger tube flattened because the

supports are not high enough to

keep the weight of the auger tube

off the wall.

Figure 8.Faulty Tube Installations

Loading...

Loading...