31

Water connections

7.2 Prerequisites

This section is intended exclusively for the Installer.

Refer to the Technical data chapter for details.

Follow the safety instructions in the "About R-290 refrige-

rant" a pag. 8.

The hydraulic system and its components must be desi-

gned by a qualied technician who must work according

to the rules of good practice and national regulations.

Check that:

• the maximum water pressure and temperature are com-

patible with the operating limits of the unit

• discharge shut-off valves are installed at the lowest

points of the system so that the circuit can be completely

drained during maintenance

• air vents are installed at the highest points of the system,

in easily accessible places

• the unit is only connected to closed hydraulic circuits.

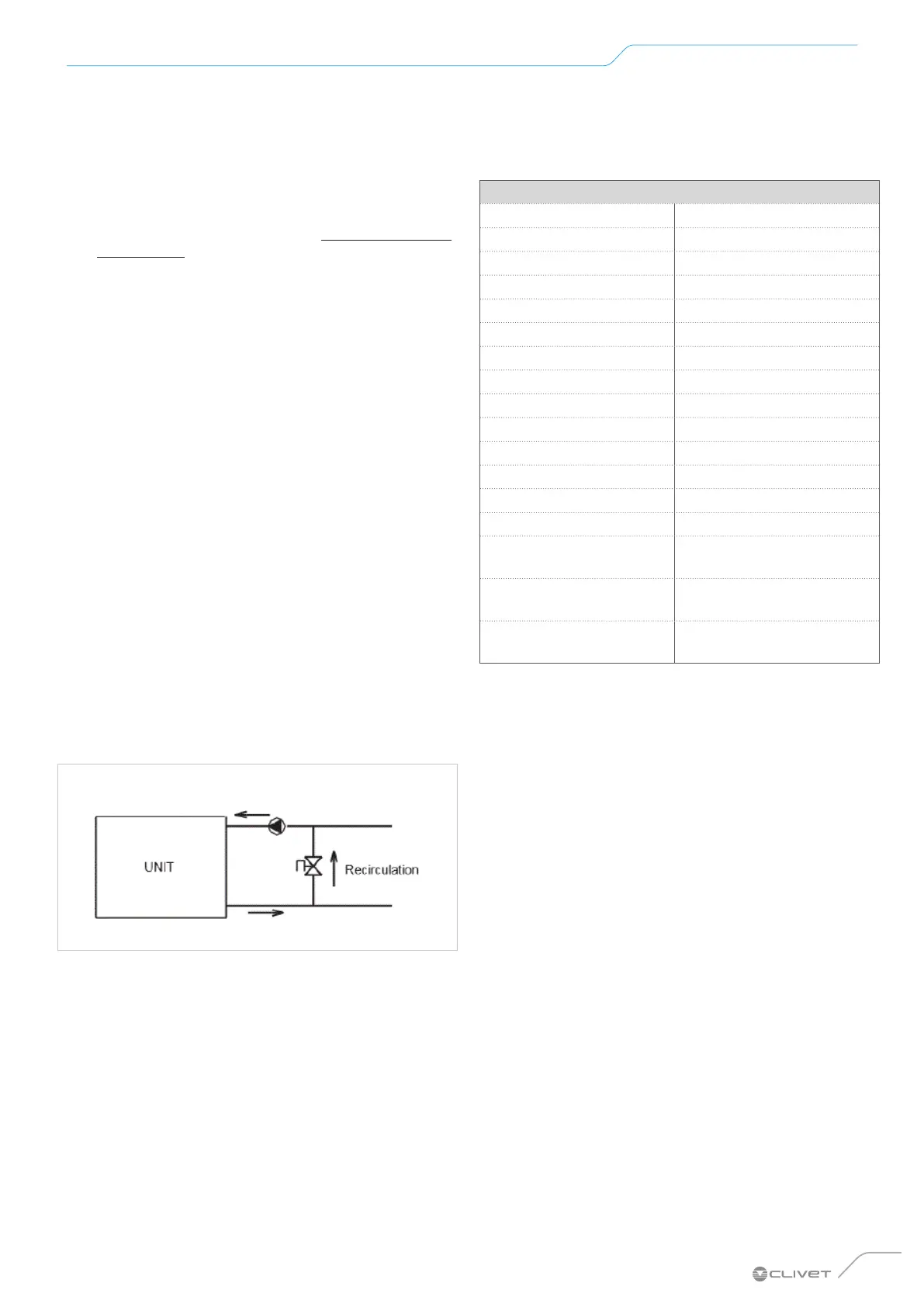

7.3 Water flow-rate

The design water flow-rate must be:

• inside the exchanger operating limits (see chapter Techni-

cal information)

• guaranteed also with variable system conditions (for

example, in systems where some circuits are bypassed in

particular situations).

If the system capacity is below the minimum flow, bypass the

system as indicated in the diagram.

7.4 Minimum water content

Check that:

• the system complies with the minimum water content

(see the Technical Information chapter)

In process applications or in environments with high ther-

mal load, additional water may be required.

When the system has areas with remotely controlled

valves, the minimum water volume must be guaranteed

even when all valves are closed.

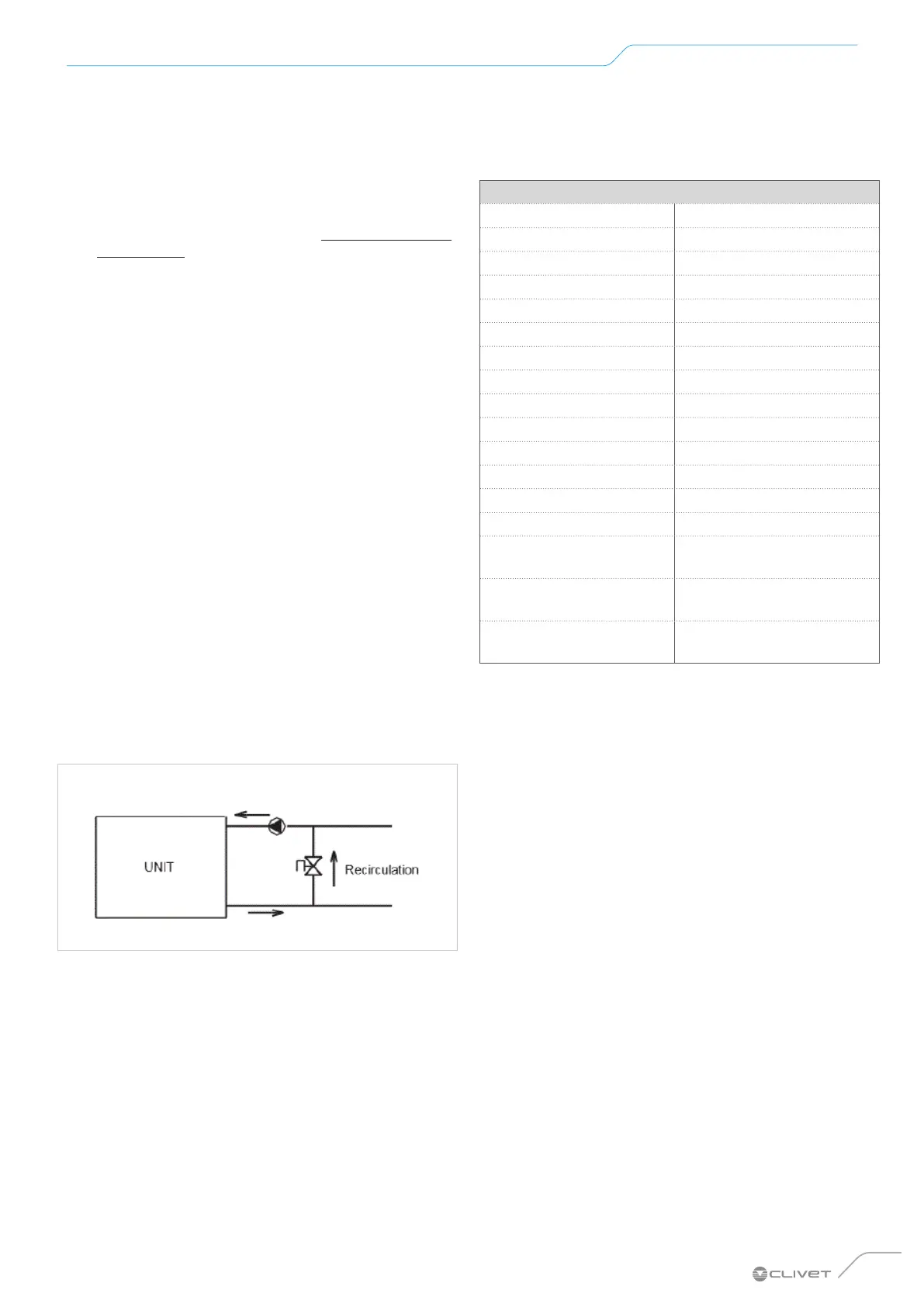

7.5 Water characteristics

The quality of the water used must be in accordance with the

requirements in the following table, otherwise a treatment

system must be provided.

Water component for corrosion limit on Copper

PH (25°C) 7,5 ÷ 9,0

SO4

--

< 100

HCO3

-

/ SO4-- > 1

Total Hardness 8 ÷ 15 °f (4.5-8.5 dH)

Cl- < 50 ppm

PO4

3-

< 2,0 ppm

NH3 < 0,5 ppm

Free Chlorine < 0,5 ppm

Fe3

+

< 0,5 ppm

Mn

++

< 0,05 ppm

CO2 < 50 ppm

H2S < 50 ppm

Temperature < 65 °C

Oxygen content < 0,1 ppm

Sand

10 mg /L 0,1 to 0,7 mm max

diameter

Ferrite hydroxide Fe3O4

(black)

Dose < 7,5 mg/L 50% of mass

with diameter < 10 µm

Iron oxide Fe2O3 (red)

Dose < 7,5 mg/L - Diameter

< 1 µm

7.6 Cleaning

Before connecting the unit to the system:

• clean the system thoroughly with specific products to

remove residues or impurities that could affect operation.

The warranty does not cover damage caused by limesca-

le build-up, deposits and impurities in the water and/or

failure of the hydraulic circuit cleaning system.

Existing systems

If a new unit is installed in an existing system:

• the system must be flushed thoroughly to eliminate any

particles, sludge and waste.

The system must be cleaned before installing the new

unit.

Dirt can be removed only with a suitable water flow

rate.

Each section must be cleaned separately.

Pay particular attention to “blind spots”, where a lot of

dirt can accumulate due to the reduced flow-rate.

If necessary, install an additional filter sized according

to the type of pollutant to be removed.

Loading...

Loading...