61

Advanced applications

14. Advanced applications

14.1 Units connected in cascade

The cascade function of the system supports a maximum of

6 units, one Master and five Slaves.

14.1.1 Water connections

The hydraulic connection should preferably be an inverted

return connection for better water balance between the

different units.

It is also mandatory to install non return valves in parallel

units to stop the flow through the unit from short circuiting

when the circulator is not in operation.

14.1.2 Electrical connections

Use shielded wire in M/S cascade connections.

To ensure auto-addressing, all units must be connected to

the same power supply and evenly powered.

14.1.3 Configuration

The configuration is carried out by setting the SW9 and S3

dip-switches.

SW9: defines the Master unit.

(Only one unit needs to be configured as Master. )

S3: sets the address of the Slave units.

Each unit on the network must be assigned an address.

S3 1,2,3

1

ON

2 3 4

0/0/0 = address 0 (master units)

1/0/0 = address 1 (slave units)

0/1/0 = address 2 (slave units)

0/0/1= address 3 (slave units)

1/1/0 = address 4 (slave units)

1/0/1 = address 5 (slave units)

0/1/1 = address 6 (slave units)

1/1/1 = address 7 (slave units)

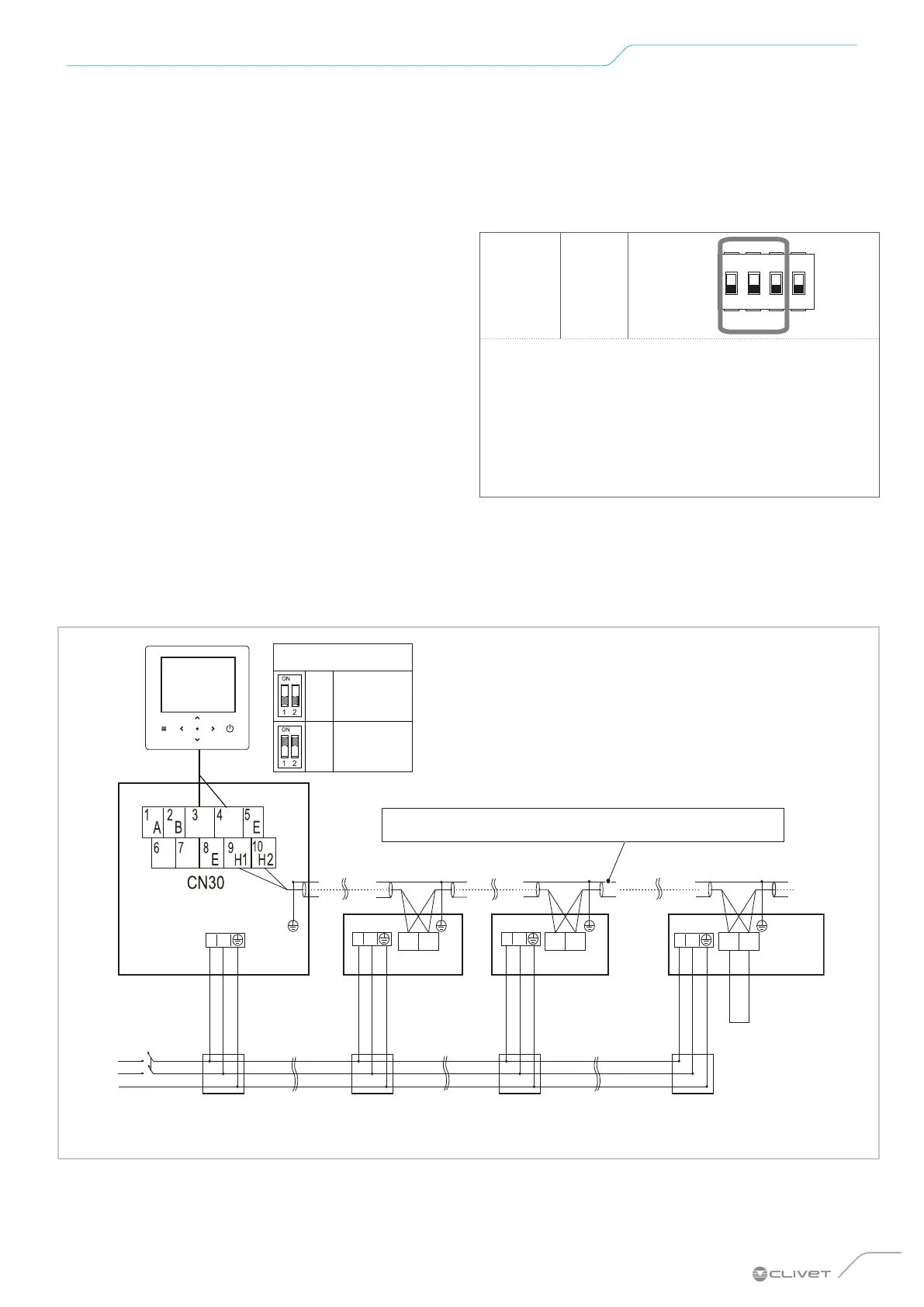

Connection diagram of the electrical control system for the cascade system (single-phase)

X/HA Y/HB

L N

L N L N

L N

Master unit

Slave unit 1

H1 H2

Slave unit 2

H1 H2

Slave unit x

H1 H2

......

ON

OFF

SW9

Slave unit

Master unit

T1 T2

Use shielded wire, the shielding layer must be earthed

Distribution

panel

Distribution

panel

Distribution

panel

External electric heater

Distribution

panel

On/Off

switch

Power supply

Only the last IDU requi-

res the addition of the

heater

H1-H2

Loading...

Loading...