33

Water connections

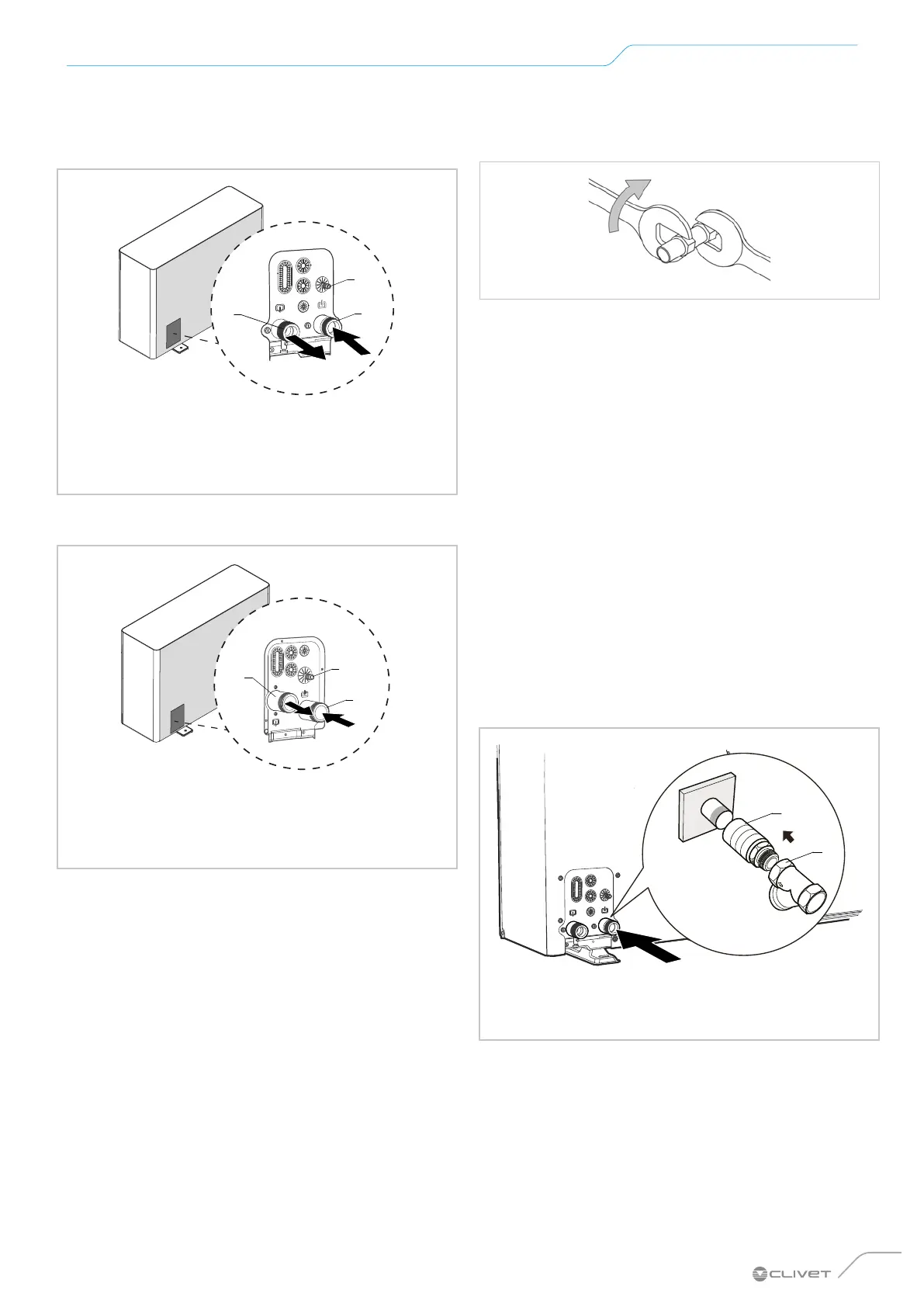

7.10 Position of connections

Sizes 2.1-3.1

3

1

2

1 1” system supply

2 Ø 16mm pressure relief valve

3 1” system return

Sizes 4.1-8.1

3

1

2

1 1 1/4” system supply

2 Ø 16mm pressure relief valve

3 1 1/4” system return

7.11 Hydraulic connection

Ensure that:

• clean piping with no moisture, air, dirt or dust is used

• the end of the pipe is kept downwards when removing

burrs

• the end of the pipe is covered when passing it through a

wall to prevent dust and dirt from entering

• thread sealant is used to seal the connections that must

withstand the pressures and temperatures of the circuit

• the two types of materials are isolated from each other to

prevent galvanic corrosion when using non-copper metal

piping

• the piping is not deformed by using excessive force or

unsuitable tools during connection: this could cause the

unit to malfunction.

Always use the wrench and counter wrench method in

tightening operations.

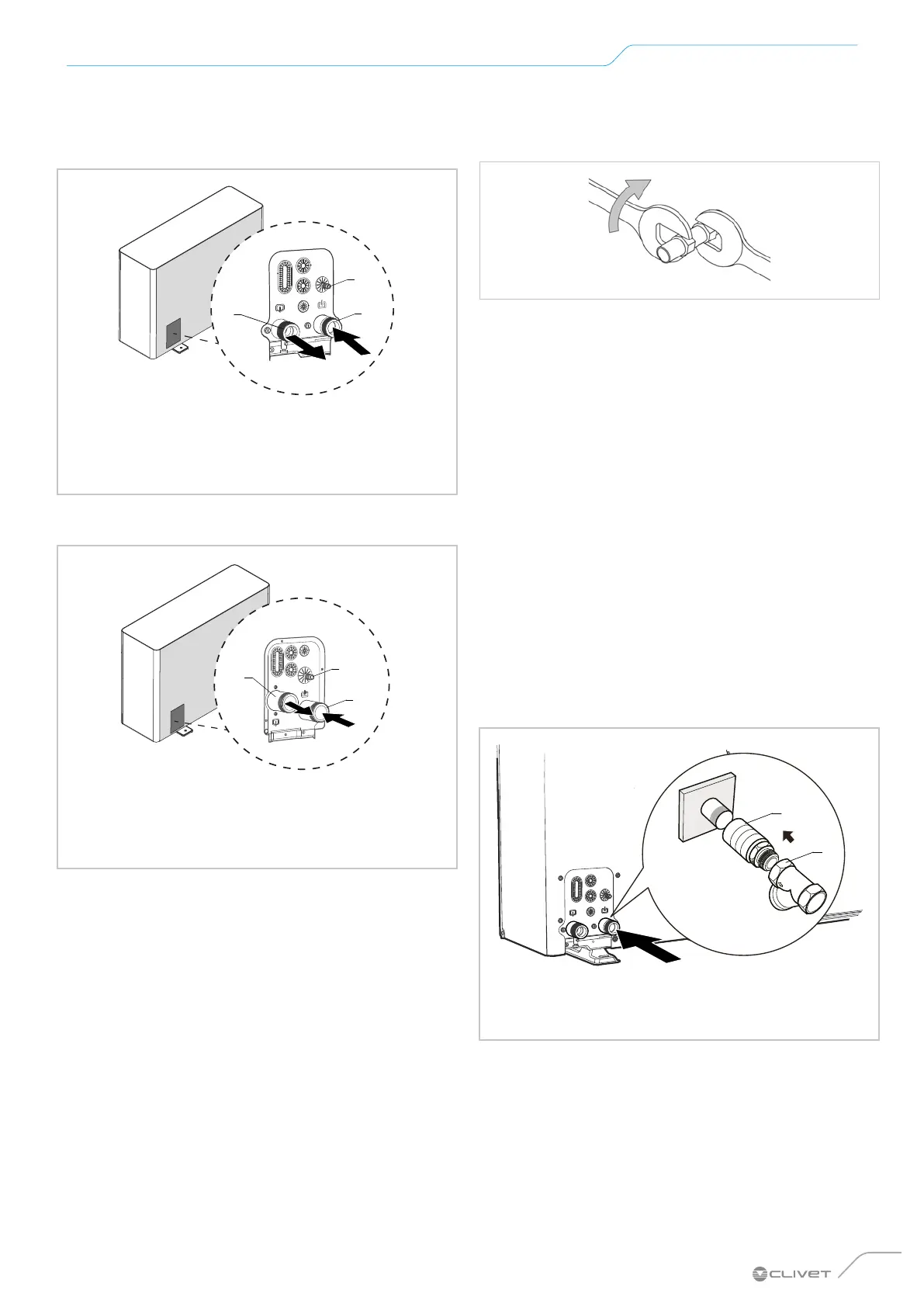

7.12 Water filter

A water filter is supplied with the unit.

As an option, a sludge remover lter is available as an acces-

sory.

Installation of the lter is mandatory.

Operation without a lter can cause irreversible damage

to the unit.

Operation without a lter will void the warranty.

Remember that the filter must be:

• installed in unit input

• easily accessible for maintenance work

Periodically check for clogging.

The lter should never be removed.

Sizes 2.1-3.1

1

2

1 Piping

2 Water filter

Loading...

Loading...