32

Water connections

7.7 Piping insulation

Isolate the entire hydraulic circuit, including all components

to avoid:

• the formation of condensation during cooling

• the reduction of heating and cooling capacity

• the freezing of external water pipes in winter.

7.8

Hydraulic circuit antifreeze protection

Outdoor temperatures close to zero can cause the water in

the piping and in the unit to freeze.

Frost can lead to irreversible damage to the unit.

Damage from freezing is not covered by the warranty.

To avoid freezing problems:

• mix the water with glycol, or

• protect the piping with heating cables laid under the

insulation, or

• empty the system in the event of long downtime

If the unit is not started for a long time, make sure it

remains powered and on stand-by.

If the power supply has to be disconnected water in the

circuit must be drained so that the unit and piping are not

damaged by freezing.

Do not reconnect the unit if there is no water in the

circuit.

In the event of an electric leakage or power failure, the

freezing protection functions cannot be activated.

7.8.1 Antifreeze solutions

For the use of freezable solutions, follow the manufacturer's

instructions.

The use of unfreezable solutions causes an increase in

pressure drops and a reduction in performance.

For details, refer to the technical bulletin.

The type of glycol used must be inhibited (non-corrosive)

and compatible with the hydraulic circuit components.

Do not use dierent glycol mixtures (e.g. ethylene with

propylene).

Glycol is a toxic uid, should not be discharged freely it

must be collected and possibly reused.

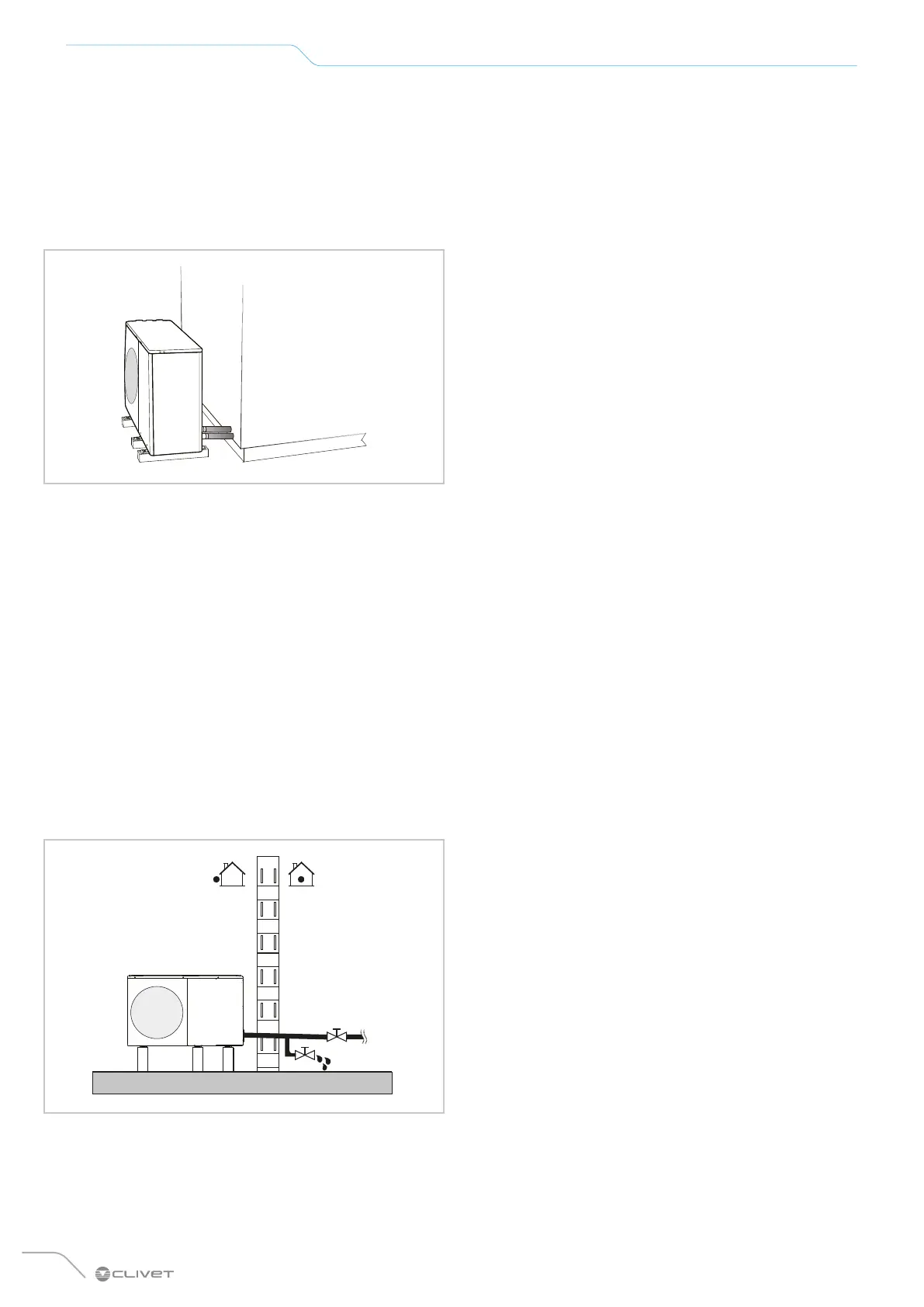

7.9 Automatic frost protection valves

Automatic frost protection valves are used to drain water

from the circuit, preventing freezing.

Install the valves in all the lowest points of the system (refer

to the accessory’s instruction sheet).

If water with glycol is used in the system, do not install

frost protection valves because they could drain the

system.

Loading...

Loading...