55

Maintenance

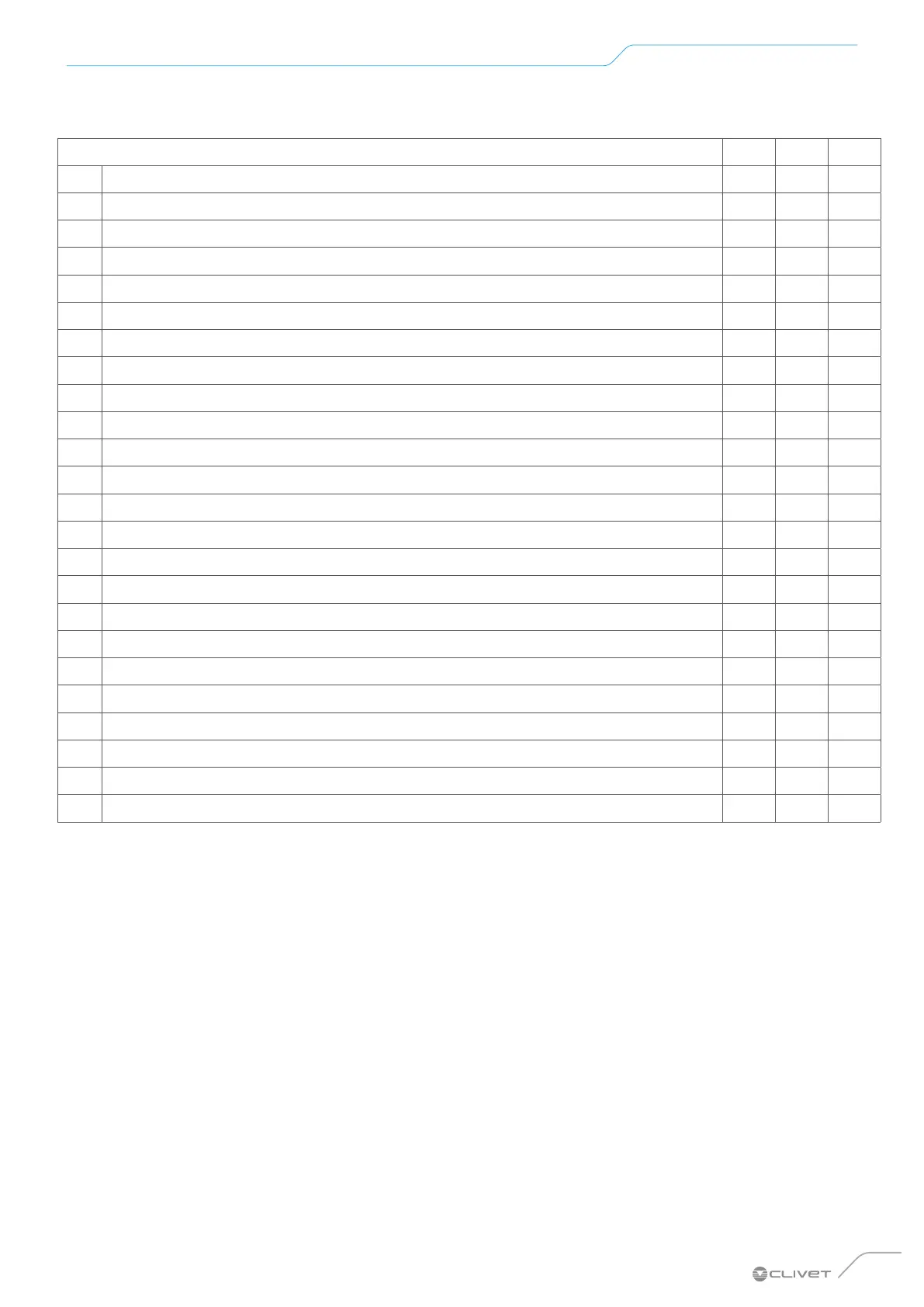

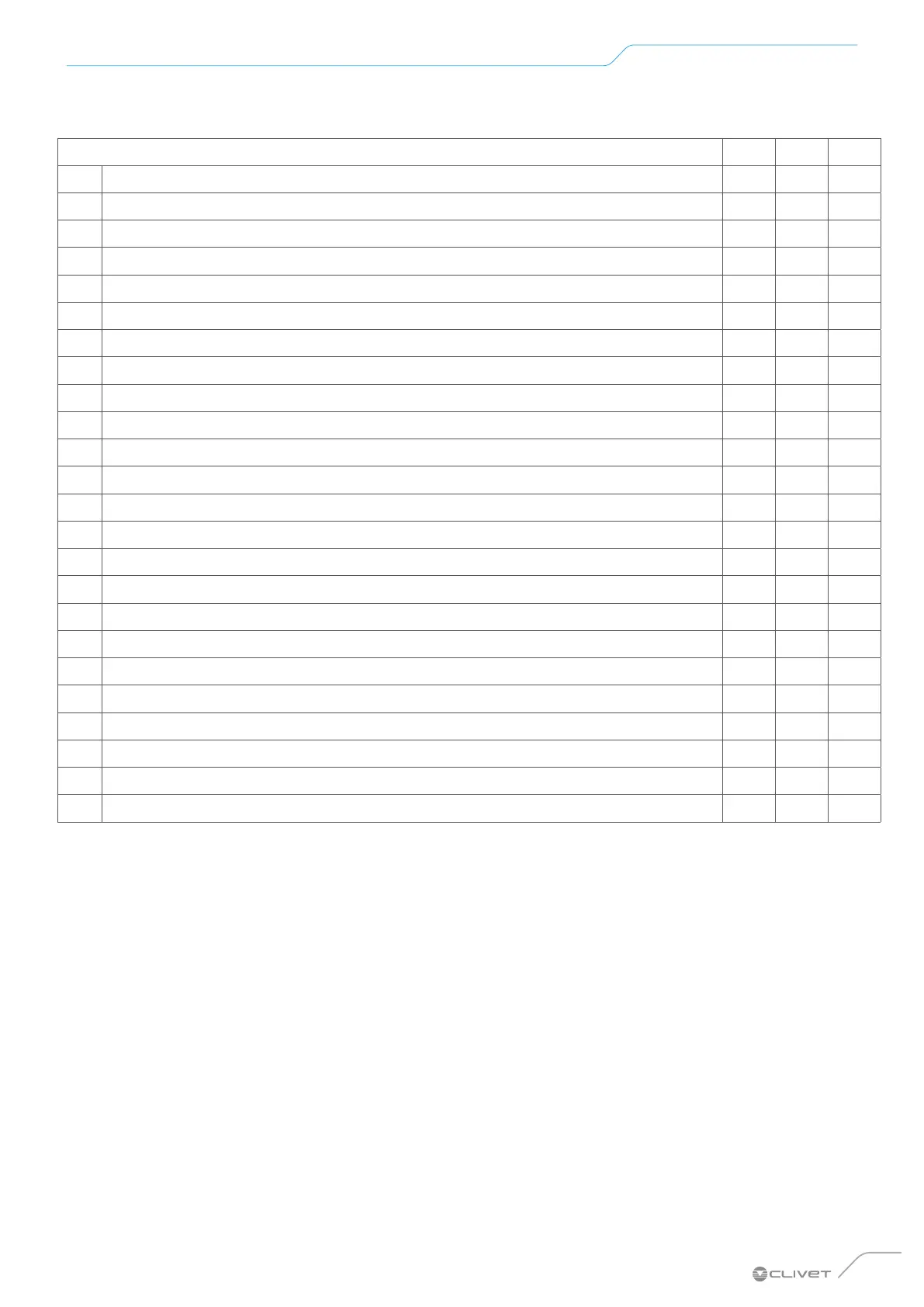

11.2 Maintenance check list

Intervention frequency (months)

1 6 12

1 presence of corrosions X

2 panel fixing X

3 fan fixing X

4 coil cleaning X

5 water filter cleaning X

6 hydraulic system filling pressure X

7 water: quality, pH, glycol concentration X

8 air in the piping X

9 circulation pump X

10 check of the fixing and the insulation of the power lead X

11 check of the earthing cable X

12 electric panel cleaning X

13 power remote controls status X

14 clamp closure, cable isolation integrity X

15 voltage and phase unbalancing (no load and on-load) X

16 absorptions of the single electrical loads X

17 compressor casing heaters test X

18 leak control * X

19 cooling circuit work parameter detection *

20 safety valve * X

21 protective device test: pressure switches, thermostats, flow switches etc.. *

22 control device test: alarm signal, thermometers, probes, pressure gauges, etc. X

23 check schedulers, setpoints, compensations, etc. X

24 fill in the unit’s booklet

*Refer to the local regulations. Companies and technicians that carry out installation, maintenance/xing, leak control and

recovery interventions must be CERTIFIED as required by local regulations.

Loading...

Loading...