150

MODBUS registers

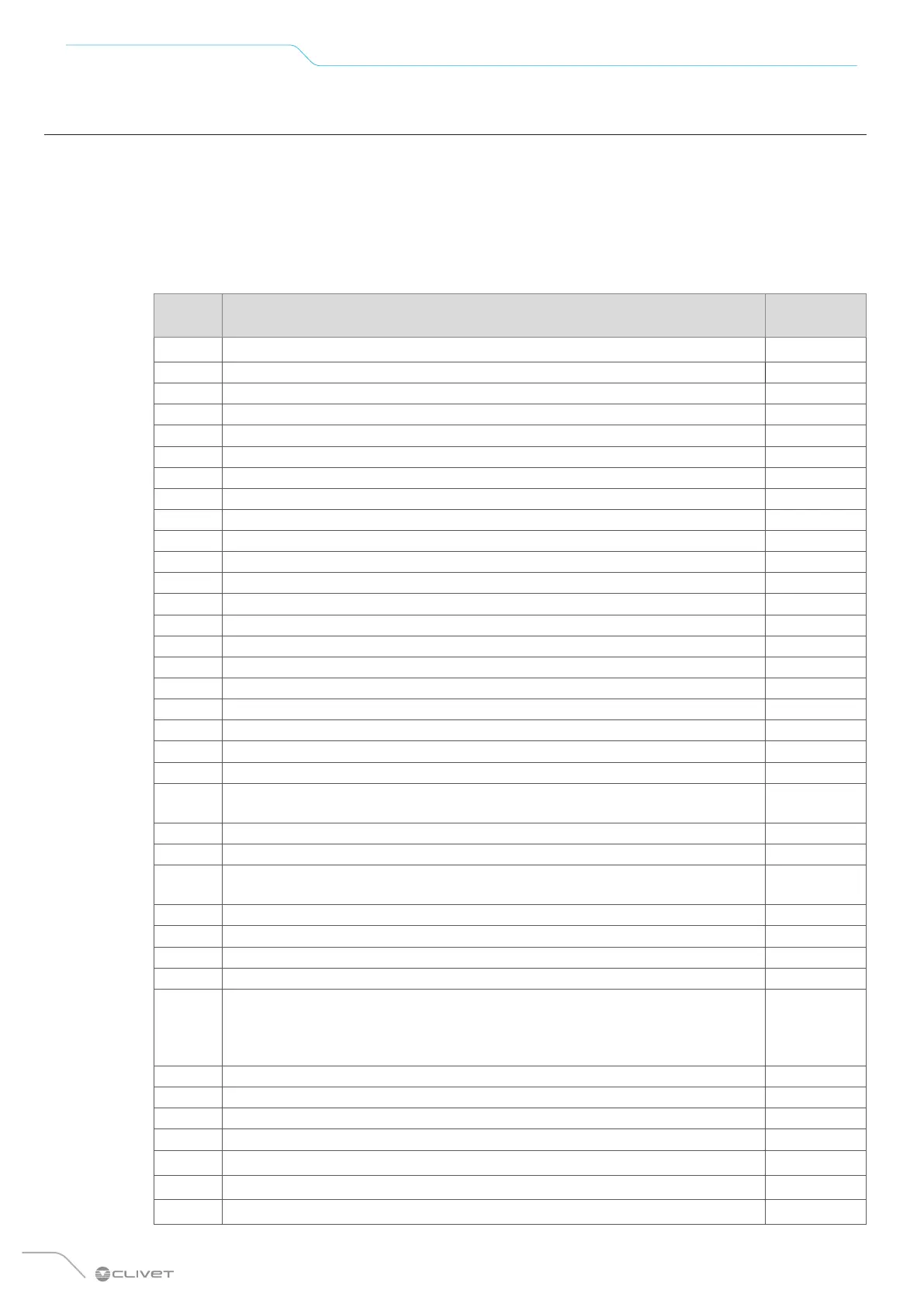

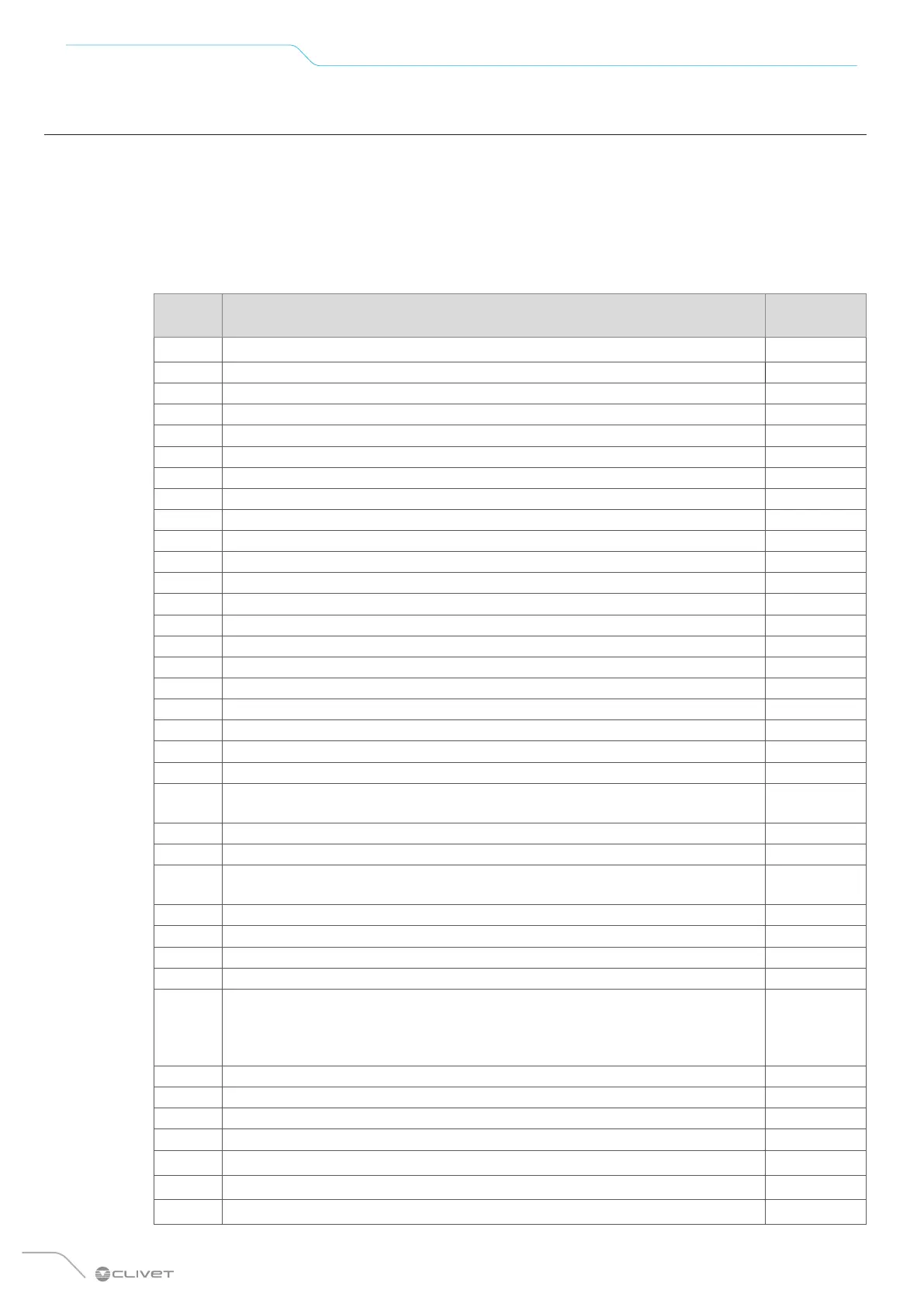

10.4 Alarms

In the event of malfunctions, alarms are indicated by the appearance of the “Active alarm” symbol on the

multifunction keypad.

To view the alarms select Menu ⊲ Service information

To reset an alarm, remove the cause of the alarm and reset the active alarm. Before resetting an alarm, iden-

tify and remove the cause of the alarm.

Repeated resets can lead to irreversible damage such as malfunction of the system itself. If in doubt, contact

a service centre.

Error

code

Description

Modbus

Code

E0 Water flow failure (water flow failure 3 times)

1

E1 Line-to-line or zero phase error (three-phase models have this error code) 33

E2 Communication error between user interface and hydraulic module 2

E3 Leaving water temperature sensor T1 failure 4

E4 Storage tank water temperature sensor T5 failure 5

E5 Unit temperature sensor T3 failure 39

E6 Unit room temperature sensor T4 failure 40

E7 Inertial storage tank sensor Tbt1 failure 6

E8 Water flow failure (displayed three times and can be reset after minutes) 9

E9 Temperature sensor Th failure 41

EA Unit air temperature sensor Tp failure 42

Eb Tsolar sensor failure 7

EC DHW additional storage tank sensor Tbt2 failure 8

Ed Water temperature sensor Twin board replacement failure 10

EE EEprom hydraulic module failure 11

P0 Low pressure protection 50

P1 Discharge temperature/high pressure control switch protection 52

P3 Compressor overcurrent protection 53

P4 Exhaust air temperature overheating protection Tp 54

P5 Twin-Twout, Twout-Twin protection or water supply temperature too high 25

P6 Module protection (IPDU and IR341) 55

Pb

Antifreeze (this is not a protection, the alarm light does not flash), the remote

control does not display Pb, but displays the antifreeze icon;

25

Pd Unit T3 over-temperature protection 57

PP Abnormal temperature dierence between entering and leaving water 31

H0

Communication error between indoor unit and unit (continuous communication

error for 10 seconds)

3

H0 Communication error between unit and indoor unit (no communication in 10 s) 38

H1 Communication error between unit and IR341 (unit and inverter module) 39

H2 Gas side refrigerant temperature sensor T2 failure 12

H3 Liquid side refrigerant temperature sensor T2B failure 13

H4

After 3 L signals (L0/L1) in 1 hour, H4 appears, which cannot be reset. After H4 it

is possible to check the last 3 L signals (not only L0, L1). For example: L0-L4-L8-

L9-L0-L1 signalling in 1 hour, H4 fault signalling. The faults to be checked are L9,

L0, L1.

44

H5 Temperature sensor Ta failure 15

H6 DC fan failure 45

H7 Abnormal power supply voltage 46

H8 High pressure sensor failure 47

H9 Sensor Tw2 failure 20

HA Plate exchanger outlet temperature sensor failure

14

Hb Three consecutive faults PP protection and Twout < 7°C; reset for power failure; 21

Loading...

Loading...