43

8 - MAINTENANCE

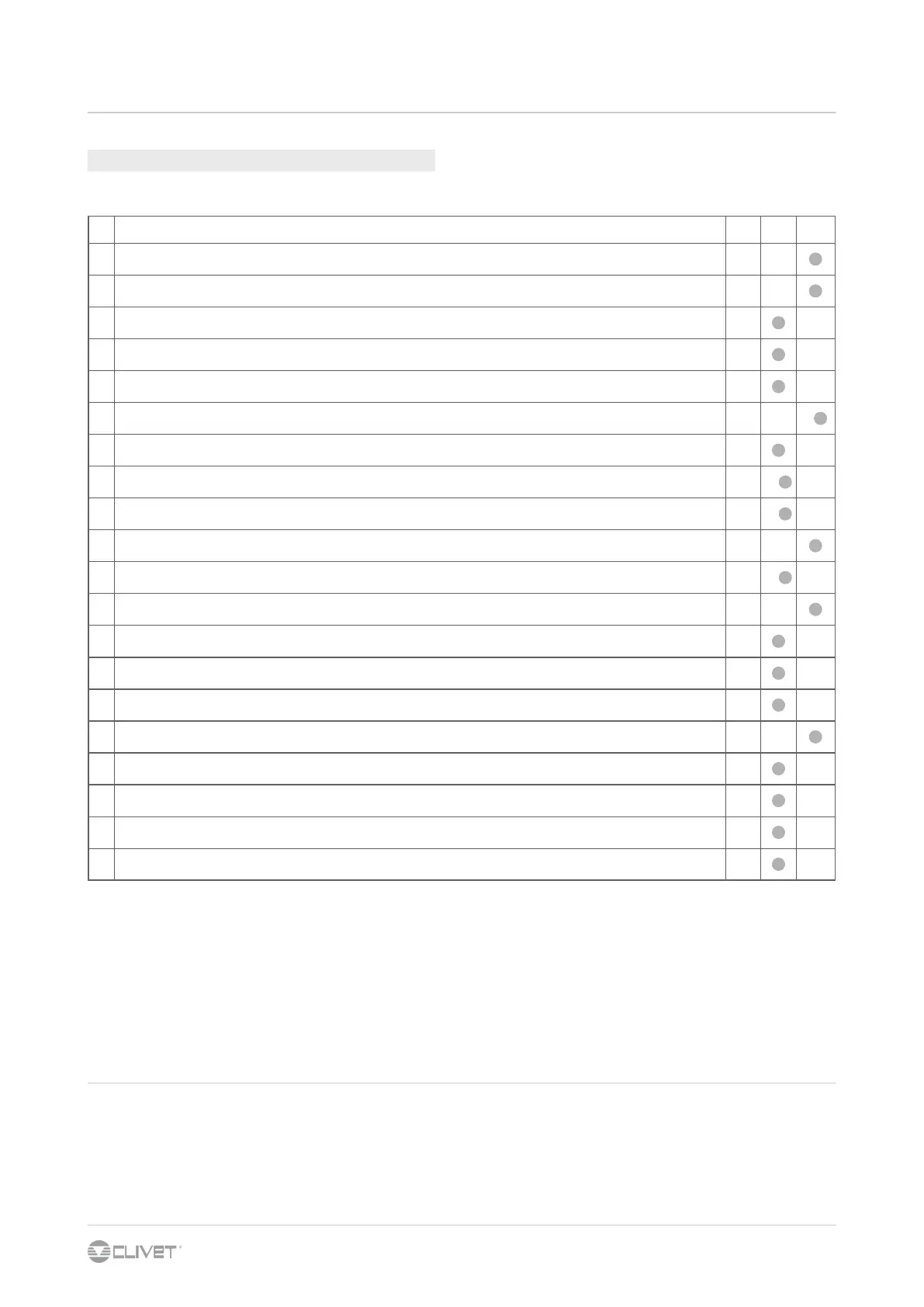

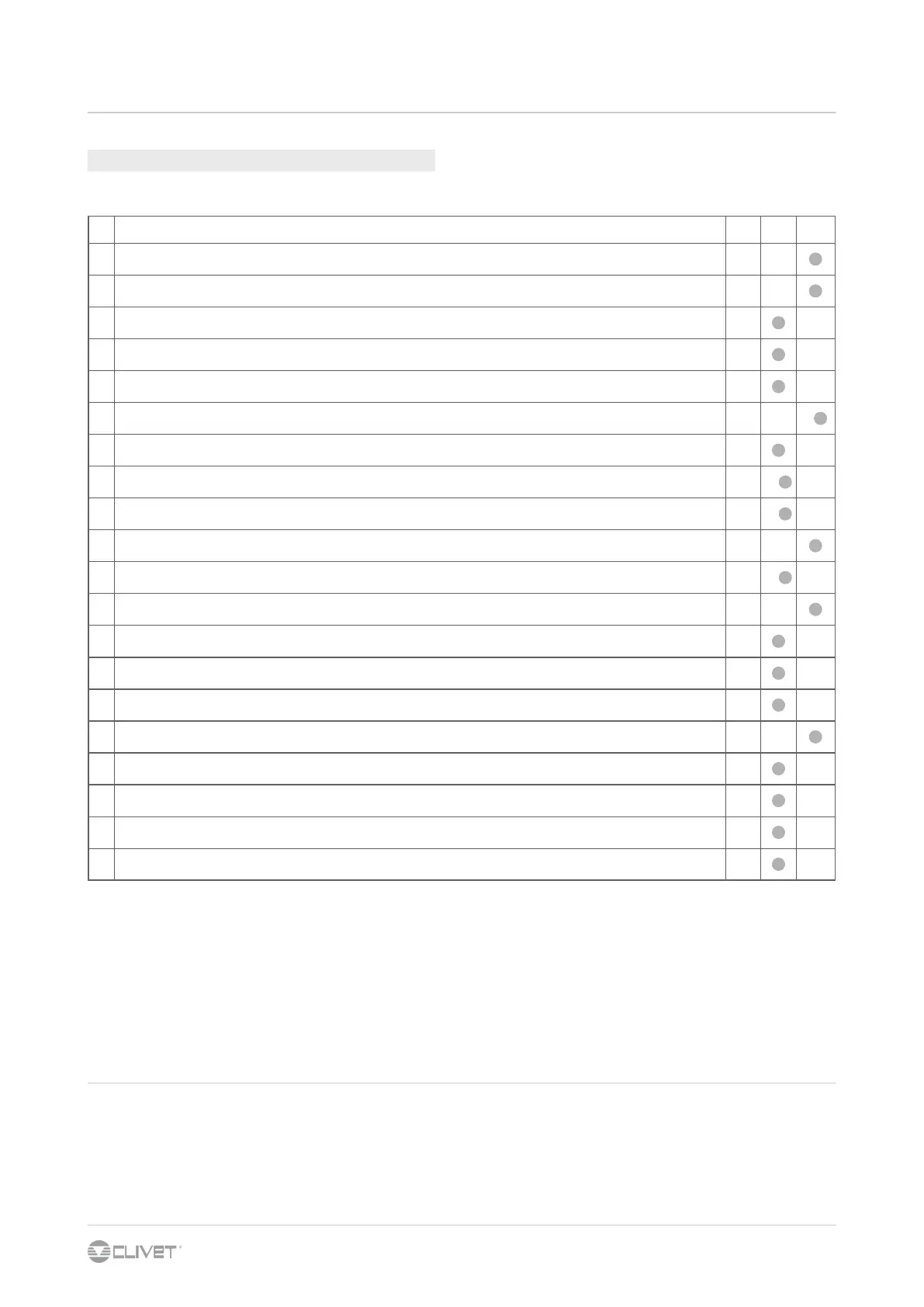

CONTROL CHECK LIST

Notes / interventions recommended to the owner

* European regulation 303/2008

Refer to the local actuation regulations; in short and just as an indication the regulation order as follow.

Companies and technicians that effect interventions of installation, maintenance/repairs, leak control and recovery must be CERTIFIED as expected by

the local regulations.

The leak control must be effected with annual renewal.

√

1 6 12

□

Presence of corrosions

□

Panel fixing

□

Fan fixing

□

Coil cleaning

□

Water filter cleaning

□

Check the exchanger efficiency

□

Circulating pumps

□

Check of the fixing and the insulation of the power lead

□

Check of the earthing cable

□

Electric panel cleaning

□

Capacity contactor status

□

Termina closing, cable insulation integrity

□

Voltage and phase unbalancing (no load and on-load)

□

Absorptions of the single electrical loads

□

Test of the compressor carter resistances

□

Leak control *

□

Survey of the refrigerant circuit operating parameters

□

Protective device test : safety valves, pressure switches, thermostats, flow switches etc

□

Control system test: setpoint, climatic compensations, capacity stepping, water / air flow-rate variations etc

□

Control device test : alarm signalling, thermometers, probes, pressure gauges etc

Controls effected on ……………………………..By ………………………………………………. Of the Company…………………..……………………………….

Loading...

Loading...