Appendices

140

C3M2-OM-EN-02

Note

Port ‘G’ Thread Specification - M12x1.5 - 12mm deep

Max tightening torque 50Nm / 37ft.lb

13. Start the engine and read the charge pressure from the gauge.

14. The pressure should read between 22 - 25 bar (320 - 362 PSI) when the engine

is idling.

15. Contact your local service representative or Combilift service if the charge

pressure is outside the specified range.

16. Remove the gauge and refit the hydraulic adapter (ensure the adapter is clean

and undamaged) and hose securely. Apply a suitable thread sealant to the

threads on the adapter before refitting.

17. Clean up any oil spills immediately.

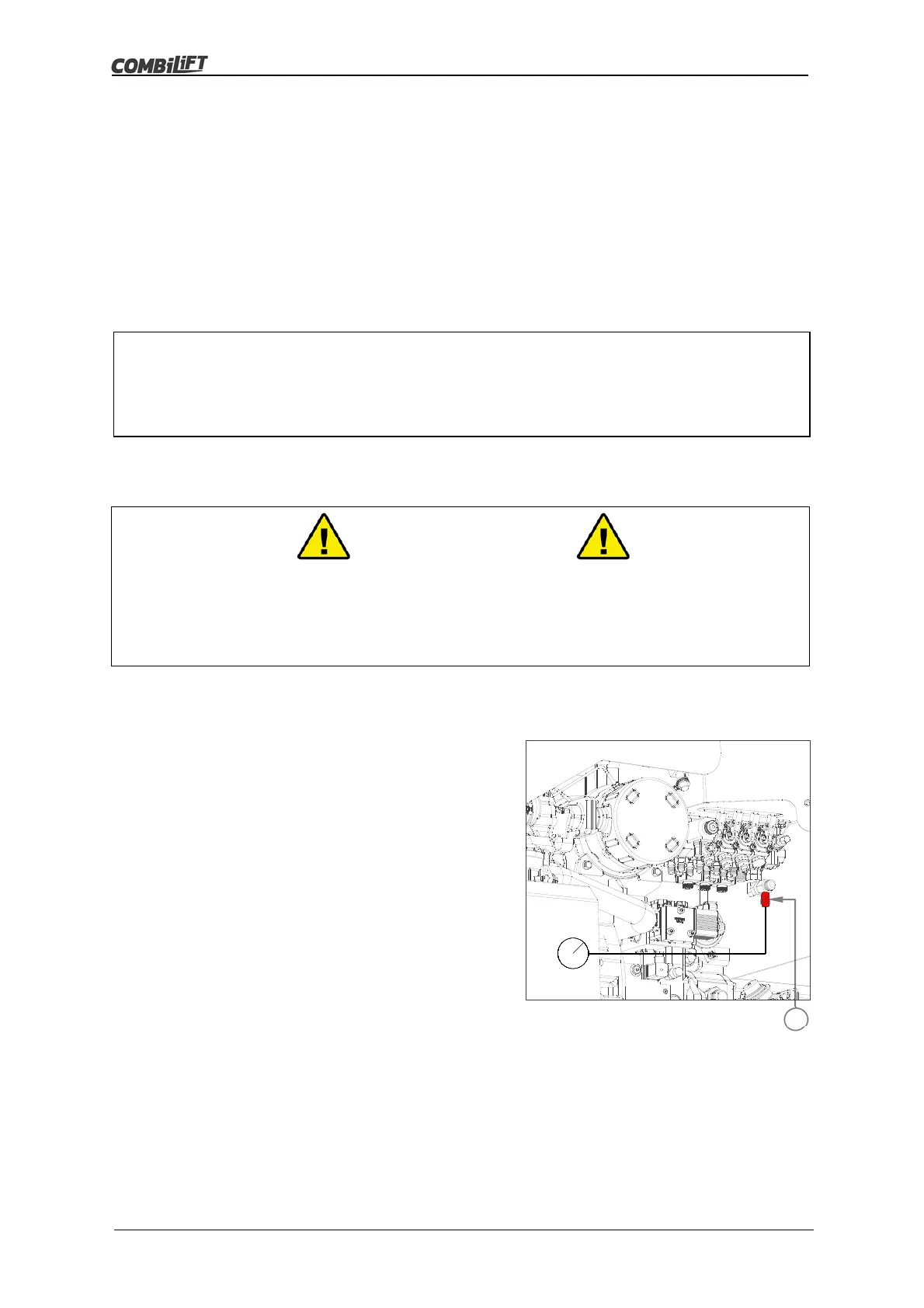

7.2 Valve Chest Pressure Settings

To check the valve chest pressure settings:

1. Park the truck in an area with

adequate space and headroom to

operate all mast functions through the

full extent of their range.

2. Extend the reach to allow access to the

pressure test point (A) on the valve

chest.

3. Lower the mast fully and tilt the mast

forward fully.

4. Turn the ignition key switch to the ‘0’ off

position, then remove the key.

5. Wait until all components in the vicinity

of the test point are cool enough to

touch or wear head resistant gloves

before proceeding.

6. Enter the area between the left-hand and right-hand platforms behind the

mast. Ensure all surfaces are clean and dry and take great care to avoid

slipping!

7. Clean and dry the test point and the surrounding area thoroughly.

Warning

Ensure that the engine is switched off until the pressure gauge has been

attached.

Ensure there is adequate space and headroom to operate each of the

hydraulic mast/fork functions through the full extent of their range.

A

Loading...

Loading...