7596004CM - Manuale EASYBLUE COMENDA ENG ok - 17 -

4.9 CONFIGURATION MANU

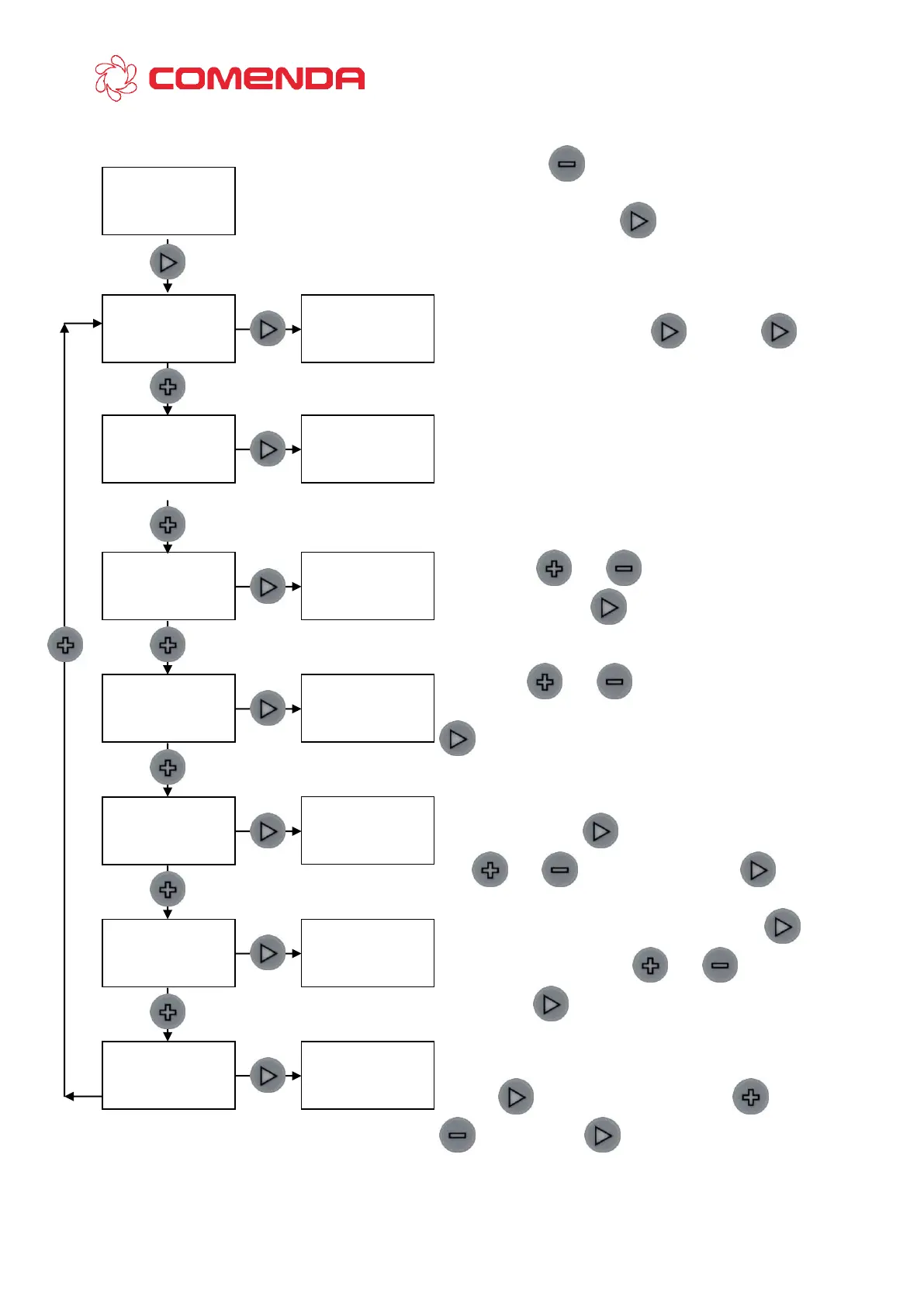

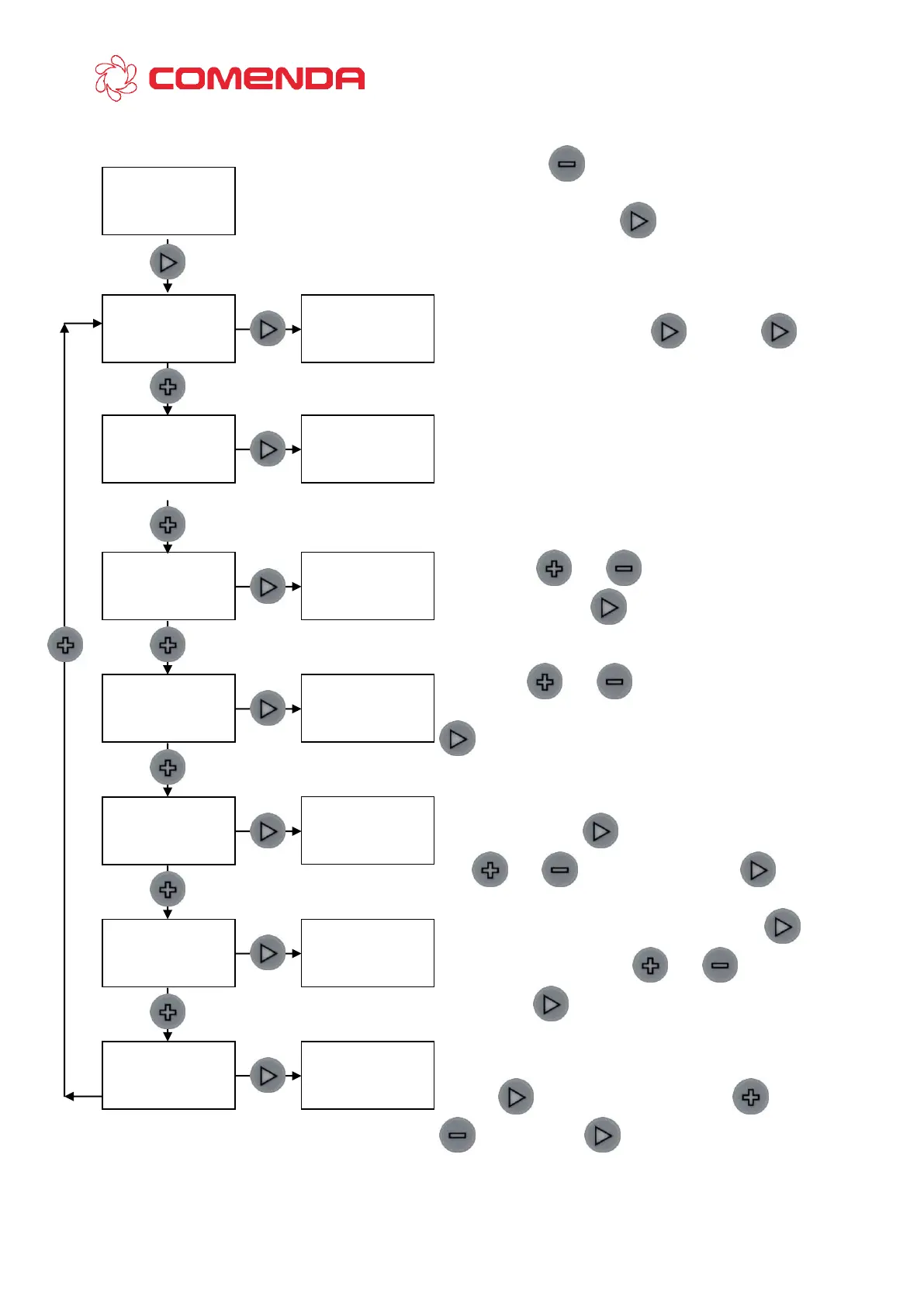

To access programming pages , press the key while connecting the power

plug.

Subsequently, the board requires you to press the key to confirm access to

programming.

The first page resets the hours of operation of the

filter. Enter in the menu with and press to

confirm.

Permits to enable/disable the automatic bypass

operated by the solenoid valve connected to the EV2

outlet, commanded by P.EV2 entrance of pressure

switch.

Use the keys and to select the stored names

and confirm with the key.

Select with and keys time operation or

without no-limits filter depletion and confirm with the

key.

Go to the change of the conversion parameter

liters/hour with the key. Change the value using

the and keys and confirm with

Change the "filter hours " parameter with the key.

Change the value using the and keys and

confirm with

Go to the change of the language conversion parameter

with the key. Change the value using and

keys and press to confirm.

Loading...

Loading...