5.9 Checking suction valve

In order to access the intake valve, the air filter has to be removed in accordance with

section 5.5.

Then open the air throttle by hand, ensuring that it has a smooth stroke and can be opened

fu

lly.

If

the air throttle jams or doesn’t operate fully, then replace the valve with a new one.

5.10 Servicing bearings of electric motor

When the compressor is used, fresh viscous lubricant (formulated for rolling bears) should

be added to the motor’s bearings.

Lubricant should be added using a special syringe for viscous lubricants through lubricators

accommodated in the motor’s bearing caps.

The volume of lubricant added can be calculated using the formula:

Do not over-lubricate the bearings beyond the standard level as all excess lubricant will be

squeezed out of the bearings into the motor when the motor is running.

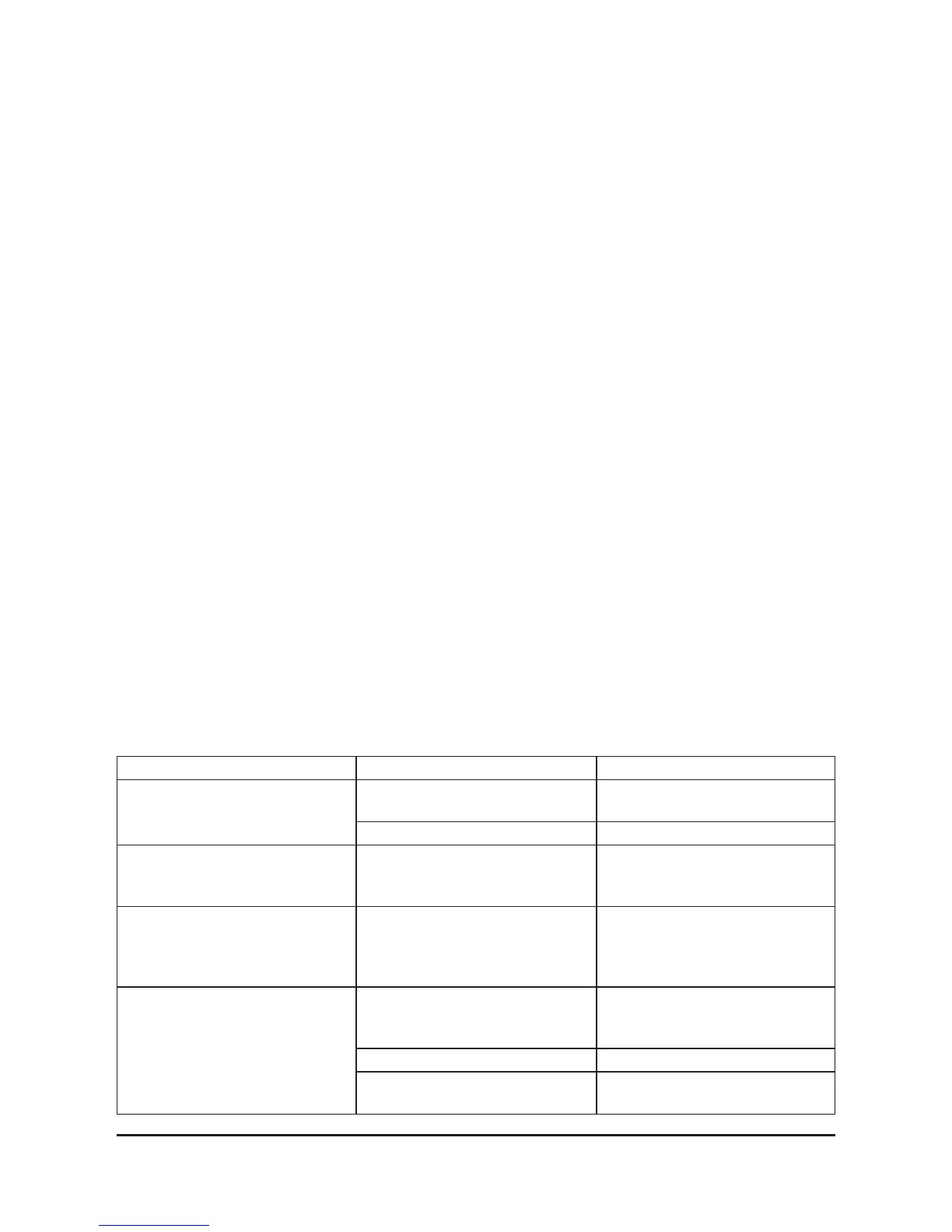

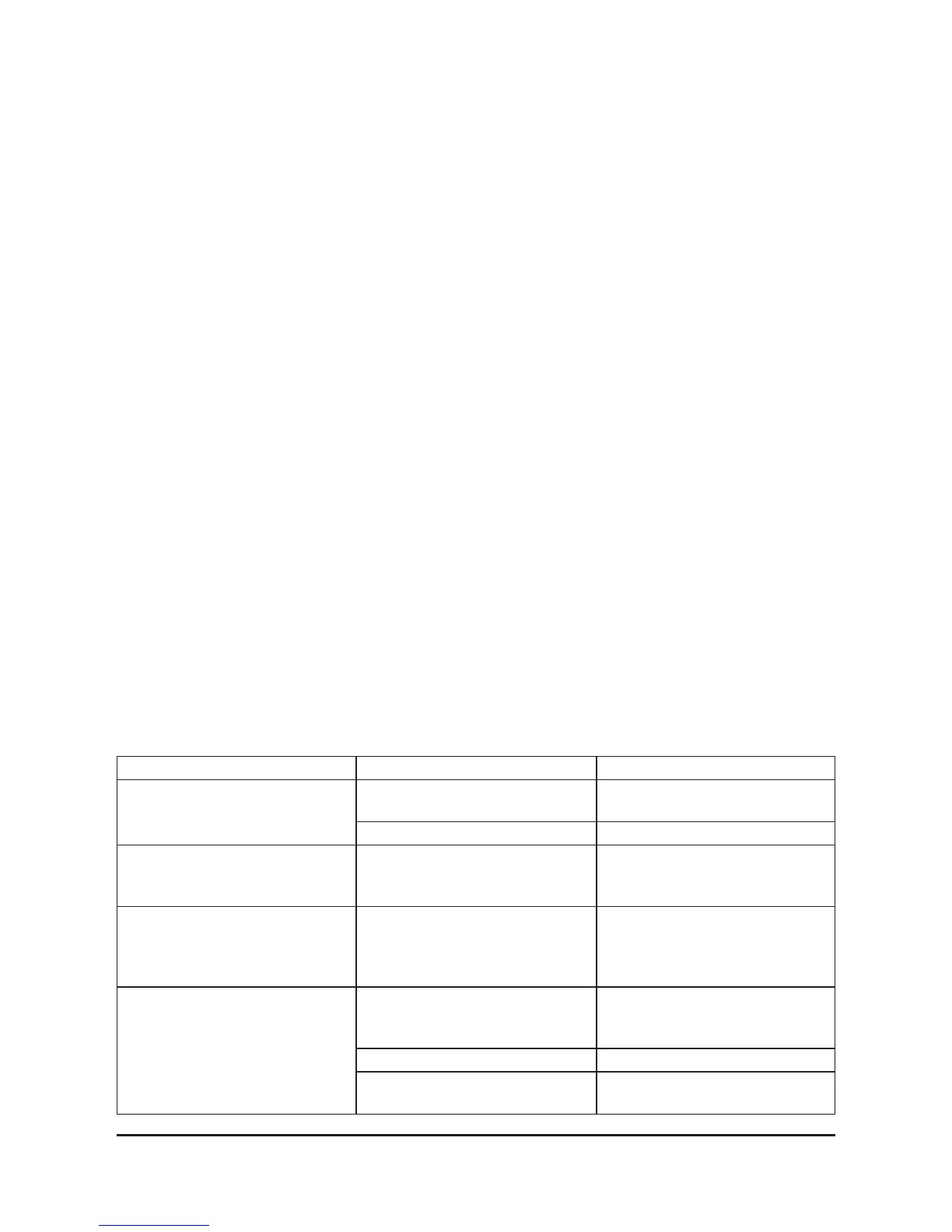

6. Fault handling

6.1 Faults and corrective actions

Problem

Possible faults Corrective actions

The compressor starts up with

lag. There is a slow build up in

the electric motor’s speed.

The belt is overtightened

Tighten the belt with the rel-

evant load.

The oil is thick. Replace the oil.

There’s a whistling during the

compressor’s operation.

The belt is slipping.

Tighten the belt with the appro-

priate tensile force (see section

5.3 Checking drive belt).

The compressor won’t start.

There’s a temperature block on

the control unit’s display.

The ambient air temperature in

the facility does not meet the

required temperature (below

+5 °C or above +40 °C).

Ensure the necessary ambi- ent

air temperature where the com-

pressor is installed.

The compressor is overheating.

There’s insufcient ventilation in

the facility where the compres-

sor is installed.

Increase the air circulation

inside the facility.

The oil level is too low. Top up oil.

The radiator is dirty Blow down the radiator with

compressed air.

D

2

motor

shaft

(mm) х 0,005 = М

(lubricant

mass)

(

g

).

Loading...

Loading...