12. Naked ames must not be used as a light source for inspecting and checking equipment.

13. Never use caustic solvents, which may damage materials of the pneumatic system.

14. After performing installation or other work, ensure that no instruments, rags or spare

parts have been left inside the equipment.

15. Pay particular attention to the safety-relief valves. Thoroughly inspect them and remove

any dust and dirt. They must not be allowed to suffer any loss in function under any circum-

stances. Remember that your safety depends on their functionality!

16. Before beginning work in normal mode after maintenance or repair work, check that the

working pressure, temperature and other characteristics are correctly set. Ensure that all

control devices are installed and functioning properly.

17. When replacing lters, separators etc., wipe away dust, dirt and oil residue from the

area where they are installed with a dry cloth.

18. Protect the motor, air lter, electrical components and control components etc. from

coming into contact with condensate. For instance, blow down with dry air.

19. Use protective gloves during installation and repair work in order to avoid burns and

injury (for instance, during oil change).

2.

Technical data and functional description

Entitlement to free handling of faults arising during the guarantee pe-

riod is forfeited when:

- No warranty service coupon for the compressor or it is

lled

out

incorrectly

- No

records

for the

compressor’s scheduled maintenance

are entered

in the

compressor’s

service book

- Unoriginal parts and

lubricants

are used

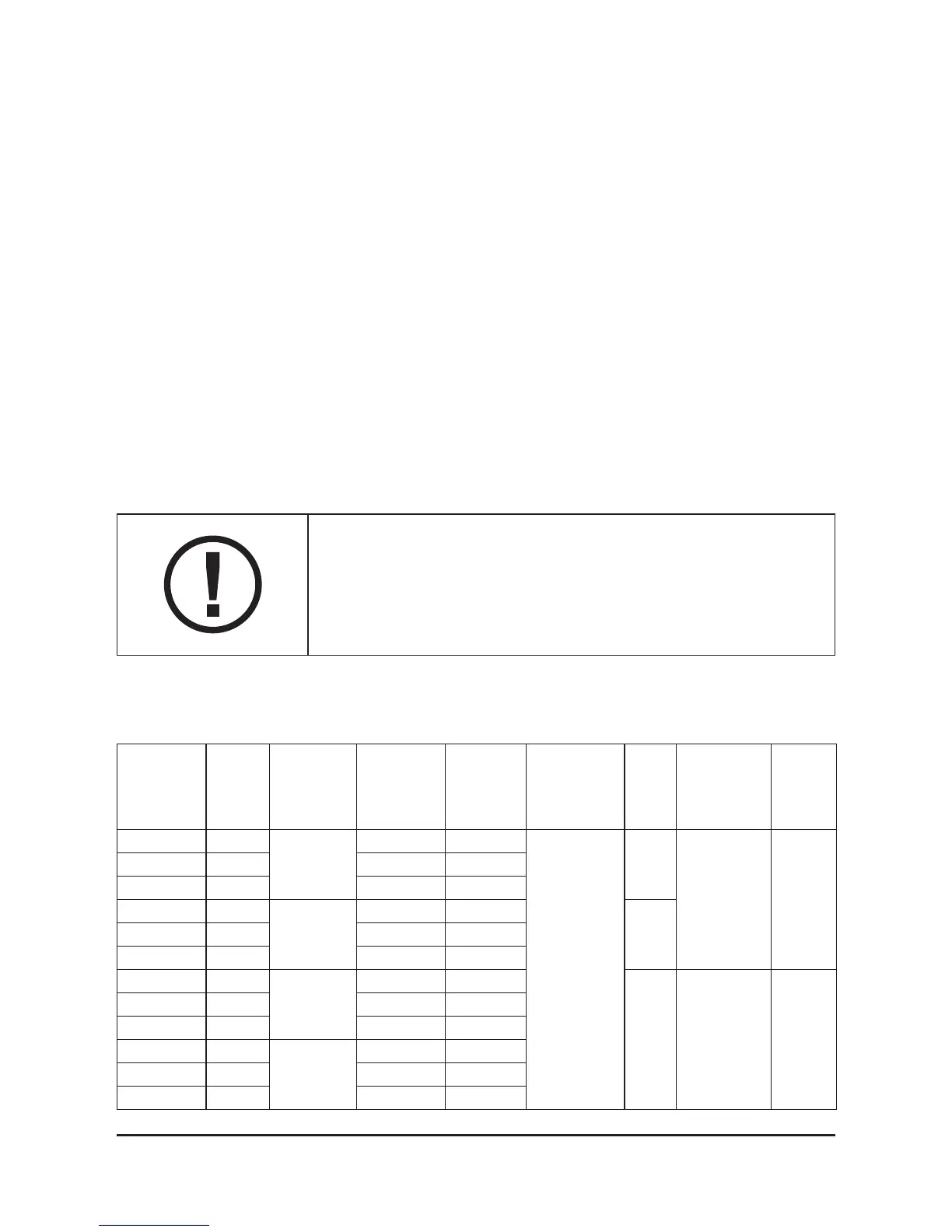

2.1 Technical data

Article Model

Drive

po

w

er

,

compressor

(kW)

Max.

operat-

ing

pressure

(bar)

Output

(m

3

/min)

Rated

v

oltage

,

compressor

(phase/V/Hz)

Noise

(dB)

Screw

connection

Oil

capacity,

liter

11100061 A3008

30

8 4,7

3/380/50

70

1-1/4

15

11100062 A3010 10 4,0

11100063 A3013 13 3,5

11100071 A3708

37

8 5,9

7211100072 A3710 10 5,1

11100073 A3713 13 4,4

11100081 A4508

45

8 7,0

73

1-1/2

20

11100082 A 4510 10 6,2

11100083 A4513 13 5,3

11100091 A5508

55

8 8,7

11100092 A 5510 10 7,7

11100093 A5513 13 6,5

Loading...

Loading...