Chapter 7 - Kohler Engine Service Access and Fuel System

206

24. Reverse the removal process to install the

engine.

• Install the engine mounting bolts loosely, then

tighten them after the heavy plate connecting the

engine to the transfer case is installed.

• Tighten fasteners to the torque specified in the

table.

• If the locking feature on any of the nuts are worn,

replace them or apply a small amount of thread

locking compound such as Loctite®

242 (blue) to

the threads. Exhaust nuts should be replaced if

the locking feature is worn.

• Check the dipstick to confirm that the engine

crankcase contains the correct amount of SAE

10W30 oil before starting it.

• Test the operation of the vehicle, and make any

needed adjustments in a safe area before

returning it to service.

* Install with releasable thread locking compound

such as Loctite®

242 (blue).

** Install with permanent thread locking compound

such as Loctite

® 262 (red).

25. Final assembly:

• Install the front fender

• Install the front spring and damper unit.

• Install the wheels

• Lower the vehicle to the ground

• Test drive the vehicle in a safe area

• Install the hood

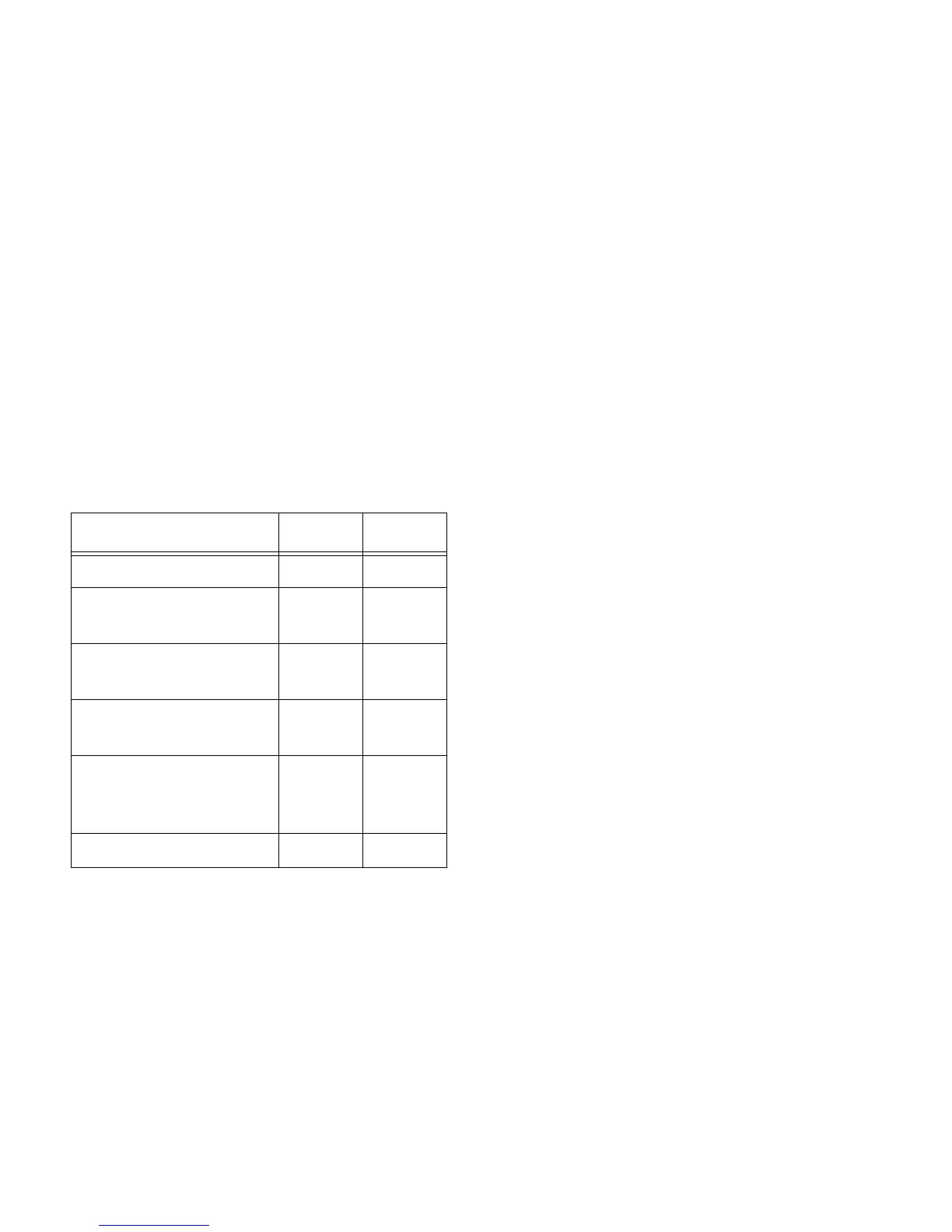

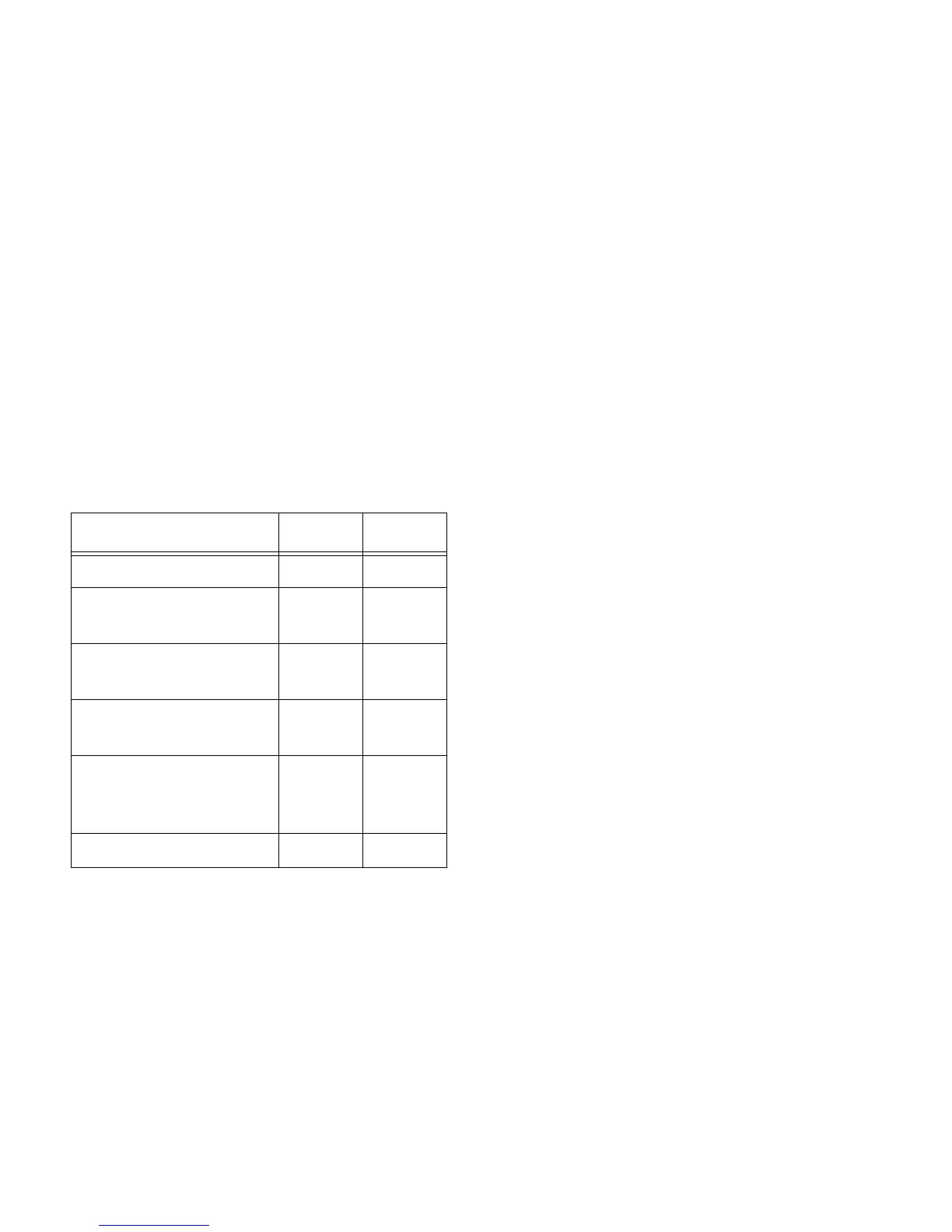

Item ft-lbs N-m

Engine to tray 32-36 43-49

Engine / Transmission

plate to engine

16* 24*

Engine / Transmission

Plate to transfer case

12* 16*

Driving element to

engine crankshaft

32-36** 43-49**

Driven element to

transfer case input

shaft

70-80** 95-

109**

Exhaust port stud nuts 32-36 43-49

Loading...

Loading...