HYDRO. DRIVE AND BRAKE SYSTEM

31

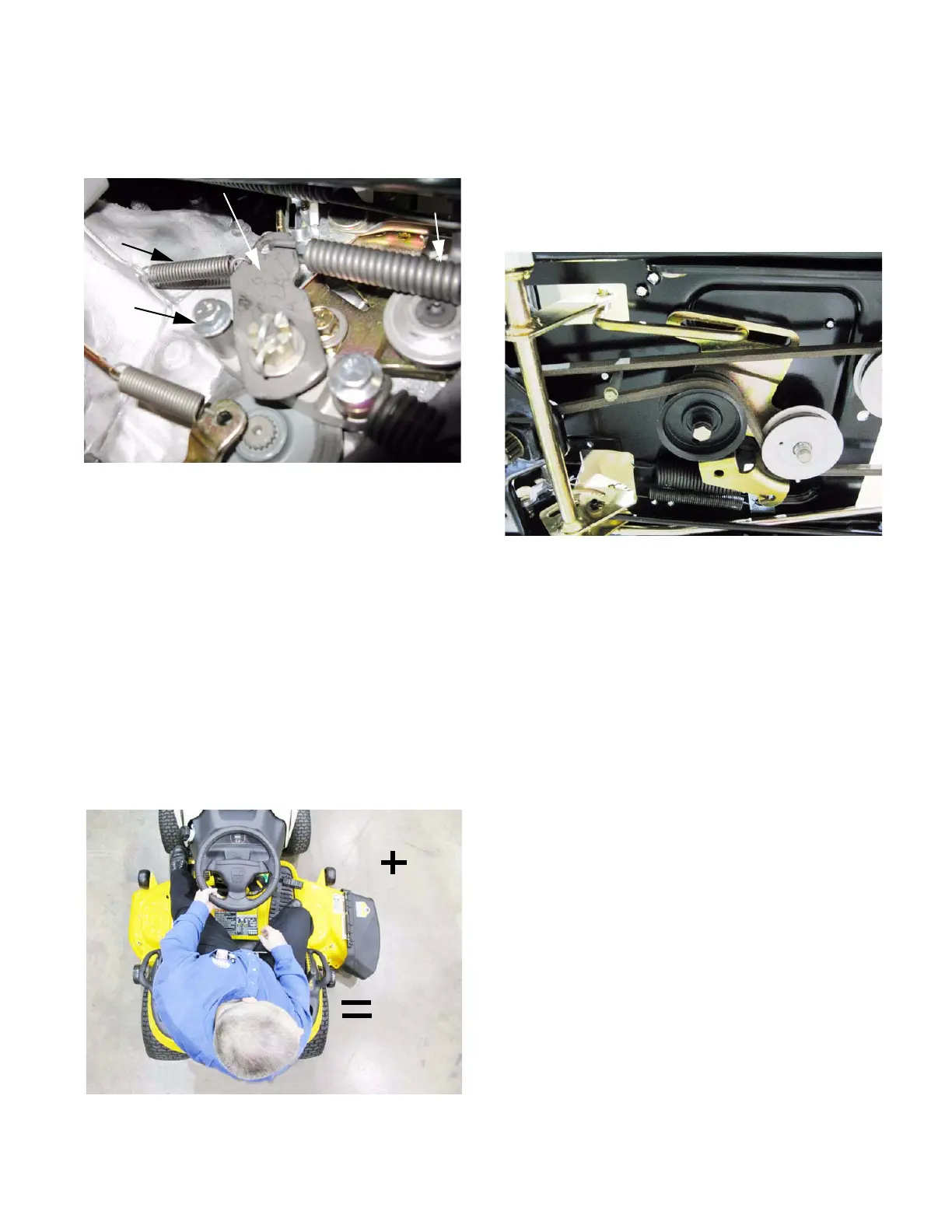

4b. If the linkage is working properly, but the

brakes seem to be dragging, check the cali-

per. See Figure 5.4.

• When the brakes are released, it should be pos-

sible to wiggle the brake rotor within the caliper.

• If the rotor is tight in the caliper, check the caliper

adjustment.

Check the operation of the caliper to confirm that

it is not stuck.

• When the brake pedal is released, the brake arm

on the caliper should fall completely back

against the stop.

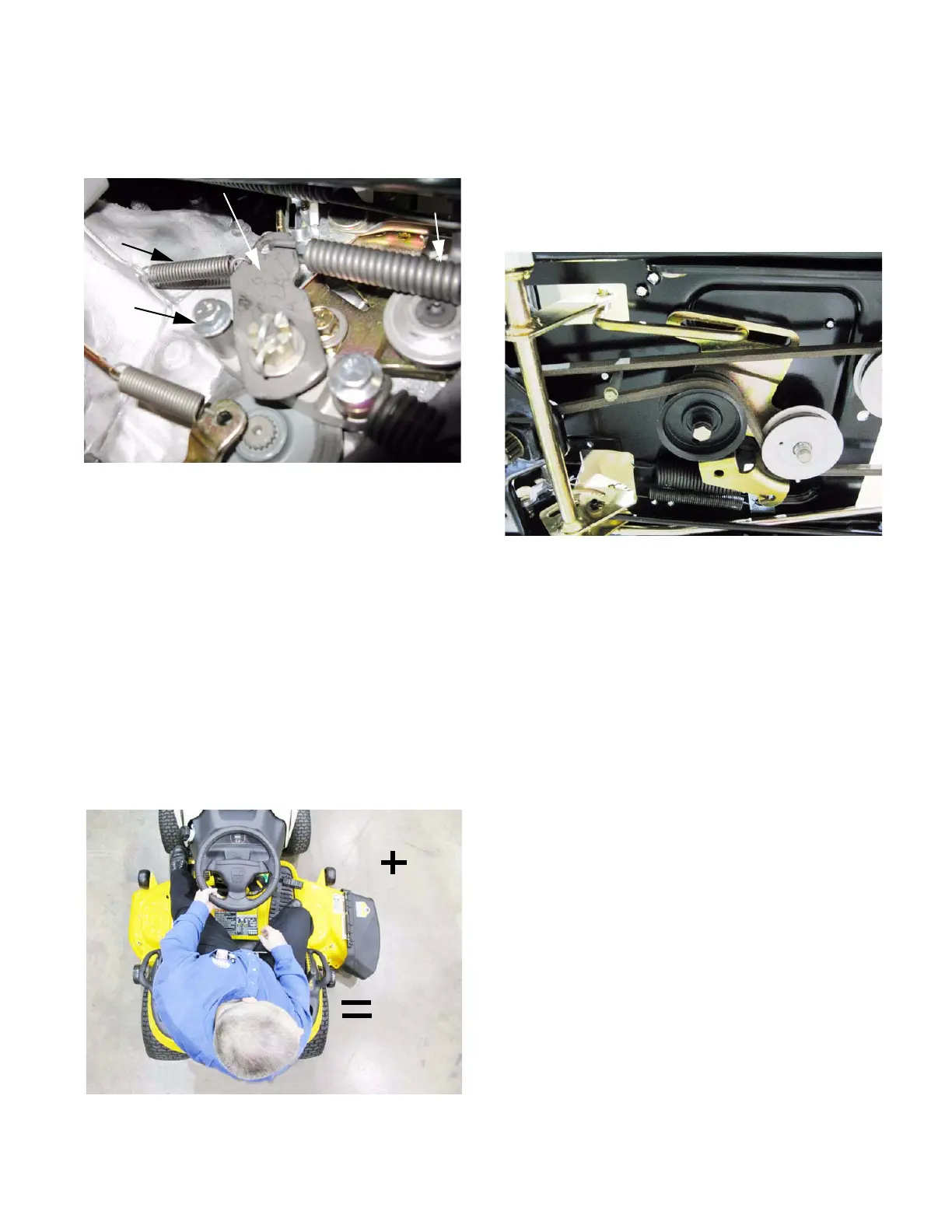

4c. Operator error: See Figure 5.5.

• If the customer complains of symptoms similar to

a brake / clutch linkage problem, yet no mechan-

ical problem is present, check the customer.

Figure 5.4

Brake

return spring

Travel stop

Brake arm

Actuator spring

Figure 5.5

Left foot on clutch

/brake pedal

Right foot on

Reverse

pedal

Operator

error

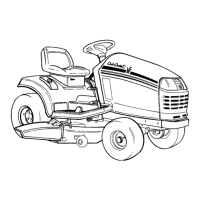

5. Check the drive belt. See Figure 5.6.

• In normal use, drive belts typically last for years

without problems.

• If the belt fails prematurely, identify and correct

the cause of the belt failure before returning the

tractor to service.

5a. Look-up the part number for the belt, and

confirm that the correct OEM belt is on the

tractor.

5b. Check the belt routing.

5c. Check the brake/clutch linkage and belt ten-

sioning pulleys.

5d. Check for foreign objects jammed against

the belt.

5e. Check for missing or out-of-place belt

guides. See the belt replacement section of

this chapter.

5f. Check the engine crankshaft and transaxle

input pulleys.

Confirm that the sheaves are not spread-

out, causing a loose belt fit.

Figure 5.6

Loading...

Loading...