Operation Section

-62-

6. Check to be sure that the LP-Gas warning plate is in

position on the lift truck, and is legible.

7. Check to be sure the replacement tank is of the

correct type.

8. Inspect the replacement tank for damage such as

dents, scrapes or gouges and for indication of

leakage at valves or threaded connections.

9. Check for debris in the relief valve, for damage to

various valves and liquid level gauge.

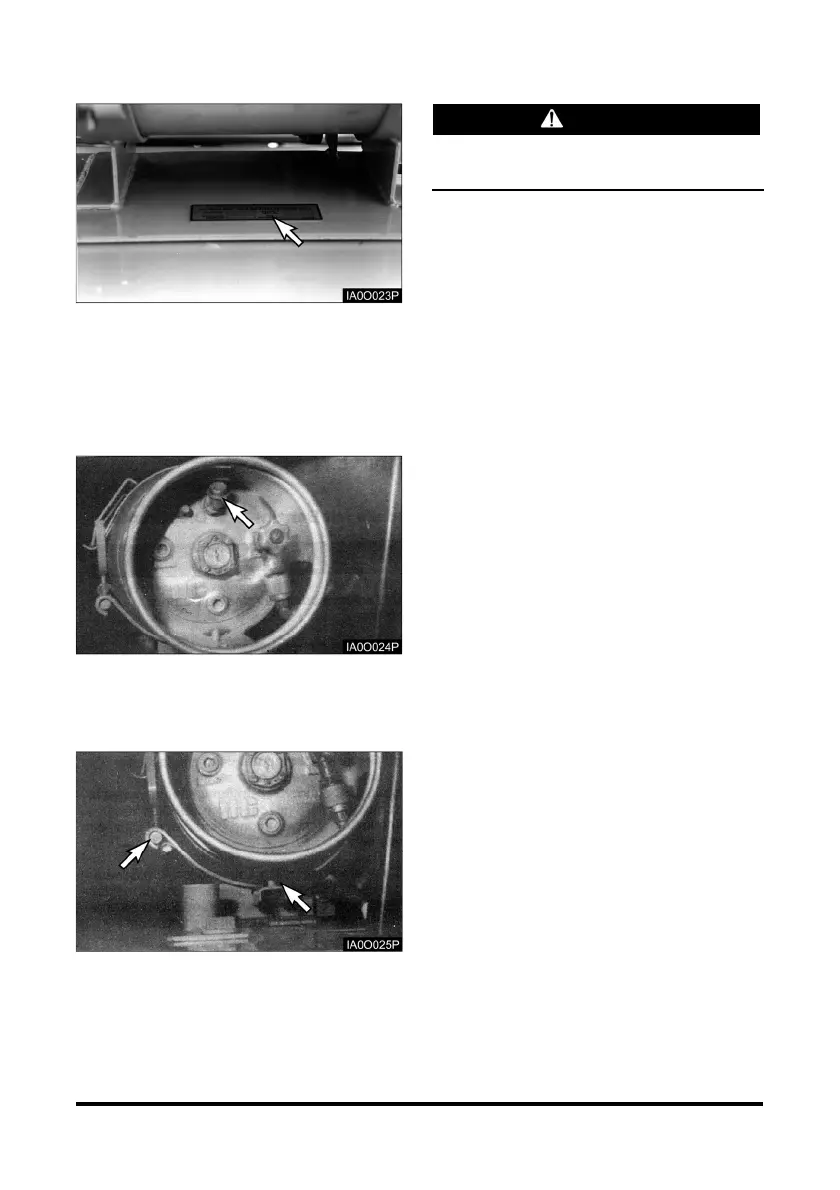

10. Inspect the quick-disconnect couplings for

deterioration, damage or missing flexible seals.

11. Position the replacement tank so that the locating

pin (dowel) is in place.

WARNING

The LP-Gas tank must not extend past the

counterweight.

12. Clamp the tank securely.

13. Connect the fuel supply line.

14. Open the fuel valve by slowly turning the valve

counterclockwise. If the fuel valve is opened too

quickly, a back pressure check valve will shut off the

fuel supply. If this happens, close the fuel valve

completely. Wait five seconds and then open the

fuel valve very slowly.

15. Inspect the LP-Gas fuel lines and fittings with a

soap solution after filling the tank or when looking

for leaks.

Loading...

Loading...